Composition, method for preparing inducing liquid from composition, application of inducing liquid in exciting heartwood formation of lignum dalbergiae odoriferae

A technology of composition and induction solution, which is applied in the application field of composition, preparation of induction solution, and stimulation of the overall aroma formation of baldwood, which can solve the problems of inability to form aromas on the whole trunk, low yield of aromas, and no breakthrough progress, etc. problems, to achieve the effect of shortening the useful life, improving output and quality, and solving technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

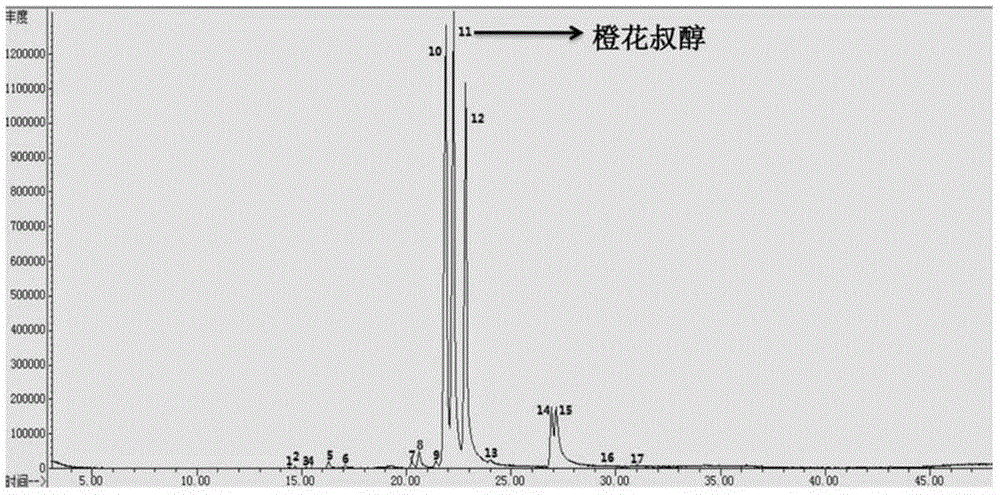

Embodiment 1

[0046] Composition formula: the dosage of the exudate extract of the bark of the balsamic bark is 0.2%, the dosage of the auxin is 0.1%, the penetration enhancer is 0.01%, and the water is 99.69%. The auxin is selected from one of gibberellin, abscisic acid and ethephon; the penetration enhancer is menthol. Menthol adopts commercially available product to get final product.

[0047] The induction solution is prepared from the above composition, step A: select the Alfalfa dalbergia, drill the heartwood of the Alfalfa, crush it, add 1-2% ethanol aqueous solution, leaching for 24 hours, filter, and prepare a mass concentration of 1-10% of the extract of the bark of the balsamic bark; step B: by weight ratio, sequentially add 0.2% of the extract of the bark of the balsamic bark obtained in step A, 0.1% of the auxin dosage, and a penetration enhancer 0.01%, water 99.69%; adjust the pH to 2.

[0048] The application of the above-mentioned inducing solution in stimulating the aroma...

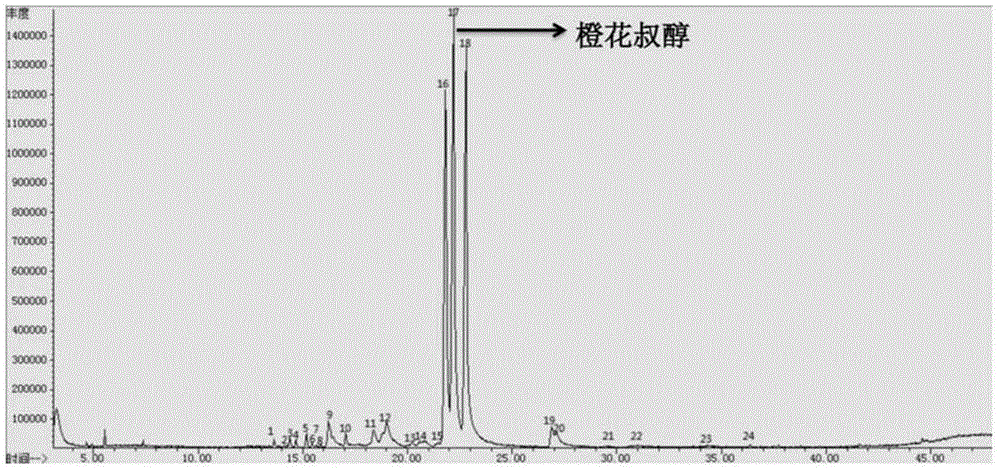

Embodiment 2

[0051] Composition formula: the dosage of the exudate extract of the bark of the balsamic bark is 4%, the dosage of the auxin is 3.5%, the penetration enhancer is 0.05%, and the water is 92.45%. The auxin is selected from one of gibberellin, abscisic acid and sodium naphthalene acetate; the penetration enhancer is menthol.

[0052] The induction solution is prepared from the above composition, step A: select the Alfalfa dalbergia, drill the heartwood of the Alfalfa, crush it, add 1-2% ethanol aqueous solution, leaching for 24 hours, filter, and prepare a mass concentration of 1-10% of the extract of the bark of the balsamic bark; step B: by weight ratio, sequentially add 4% of the extract of the bark of the balsamic bark obtained in step A, 3.5% of the auxin dosage, and the penetration enhancer 0.05%, water 92.45%; adjust the pH to 2.5.

[0053] The application of the above-mentioned inducing solution in stimulating the aroma of balsamic:

[0054] Select 30 balsamic trees th...

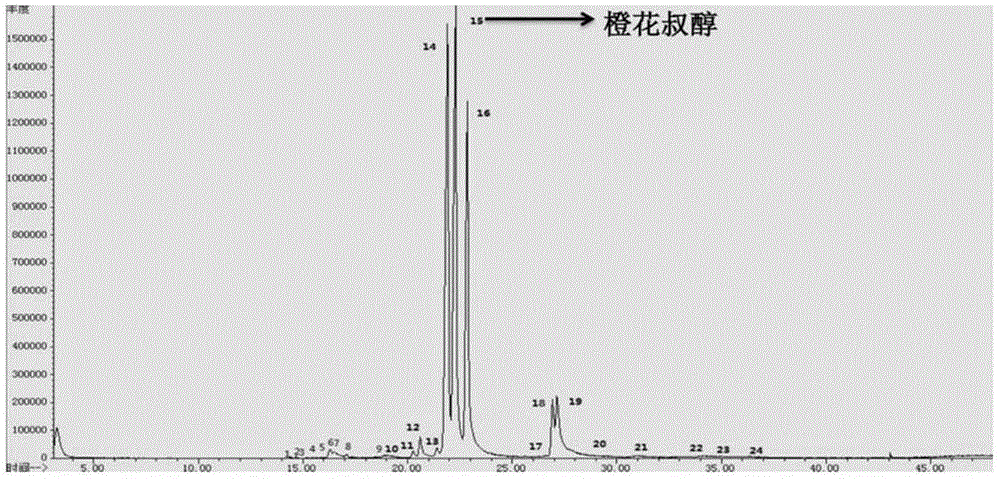

Embodiment 3

[0056] Composition formula: the dosage of the exudate extract of the bark of the balsamic bark is 10%, the dosage of the auxin is 10%, the penetration enhancer is 0.1%, and the water is 79.9%. The auxin is selected from one of abscisic acid and sodium naphthalene acetate; the penetration enhancer is peppermint oil. The peppermint oil can be commercially available.

[0057] The induction solution is prepared from the above composition, step A: select the Alfalfa dalbergia, drill the heartwood of the Alfalfa, crush it, add 1-2% ethanol aqueous solution, leaching for 24 hours, filter, and prepare a mass concentration of 1-10% of the extract of the bark of the balsamic bark; step B: adding 10% of the extract of the bark of the balsamic bark obtained in the step A, 10% of the dosage of the plant auxin, and a penetration enhancer 0.1%, water 79.9%; adjust the pH to 3.

[0058] The application of the above-mentioned inducing solution in stimulating the aroma of balsamic:

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com