Slope clearance adjusting axial rolling device of large ring rolling machine

A technology of axial rolling and ring rolling machine, applied in the field of hot rolling forming equipment for seamless ring parts, can solve the problems of reduced frame stiffness and strength, high machining accuracy requirements, and unsuitable front and rear guide rail loads, etc. The effect of reducing weight, convenient frame processing, and simplified shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

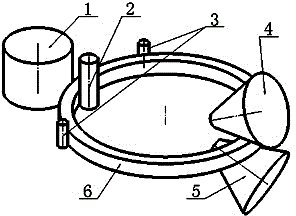

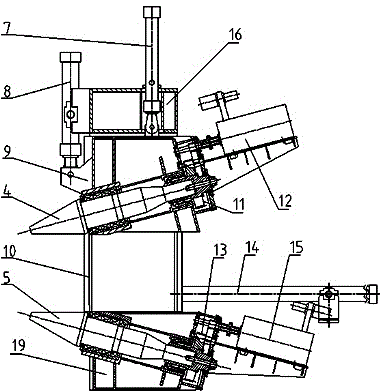

[0023] Such as figure 2 As shown, an axial rolling device of a large-scale ring rolling machine with an inclined plane gap adjustment, the main structure is composed of a frame 10, a slider 9, an upper tapered roller 4, and a lower tapered roller 5, and the axial rolling device is provided in the The mobile oil cylinder 14 for forward and backward movement power on the base of the whole machine, the motors (12, 15) in the rotary power system of the upper and lower tapered rollers, the upper reduction box 11, and the lower reduction box 13 provide the main rolling block for sliding up and down and rolling force. Oil cylinder 8 and balance oil cylinder 7 etc. are formed.

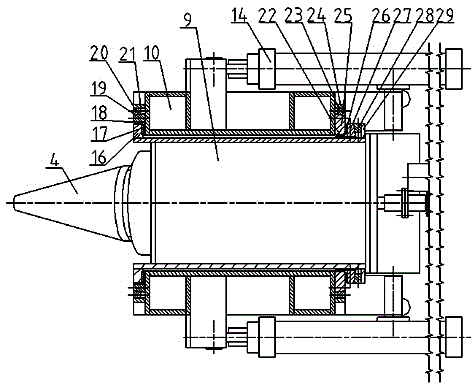

[0024] Such as image 3 As shown, the present invention includes a frame 10 and a slide block sliding along the frame, first to sixth gap adjustment mechanisms are arranged between the frame and the slide block, and the first gap adjustment mechanism and the second gap adjustment mechanism are symmetrical A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com