A liner transfer assembly machine

A conveyor and assembly machine technology, applied in metal processing, grain processing, metal processing equipment, etc., can solve the problems of easy injury of workers and high labor intensity of lining plates, and achieve the effects of reasonable structure, convenient installation and disassembly, and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

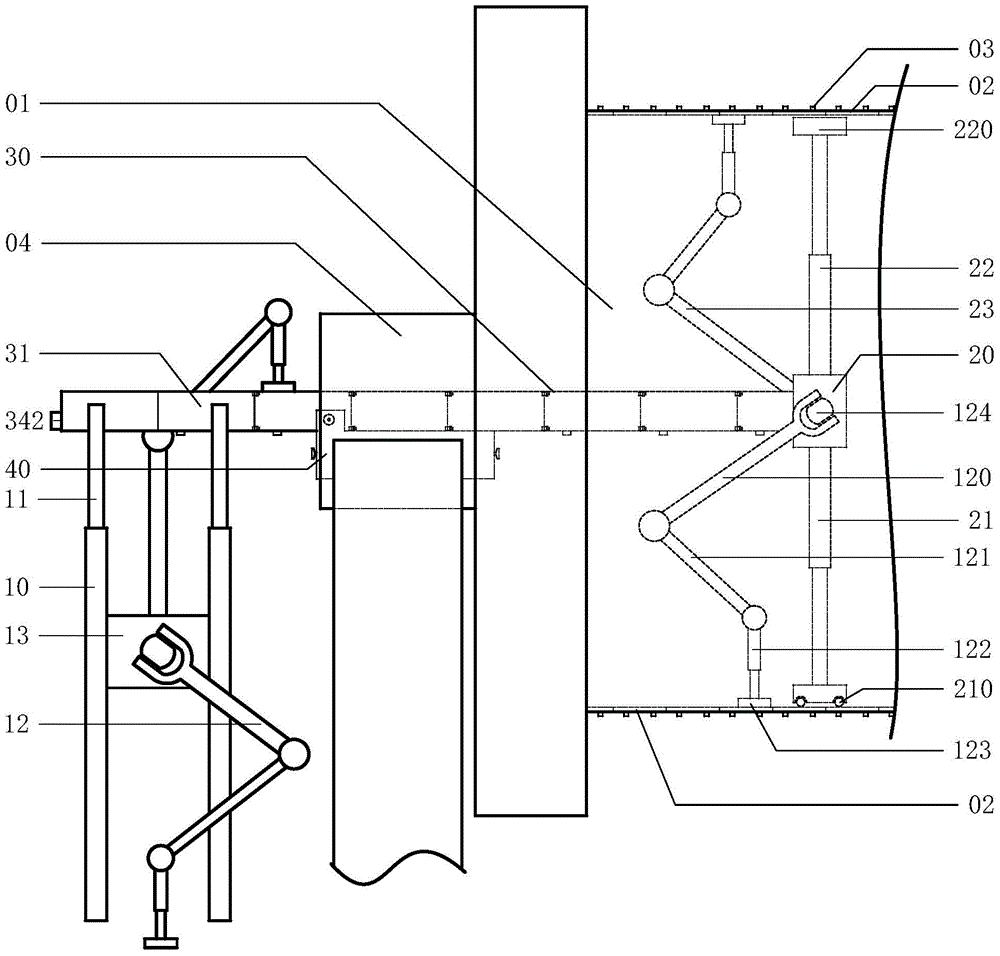

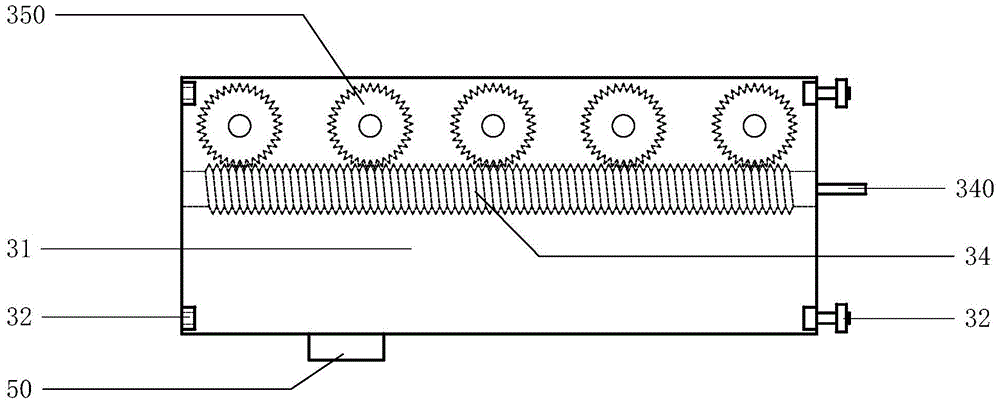

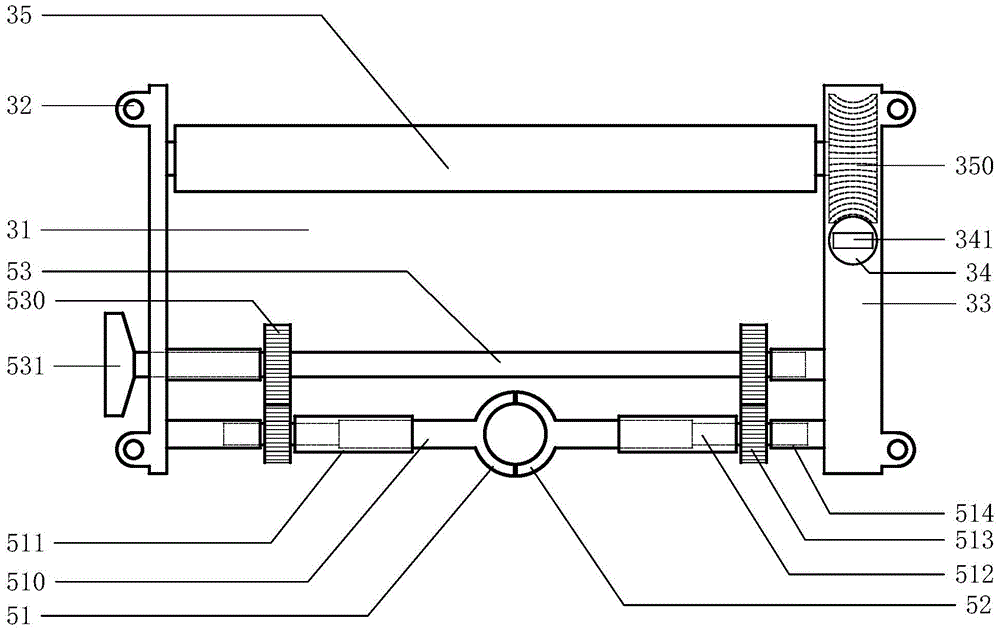

[0021] see figure 1 and combine figure 2 , 3 , 4. The liner plate transmission assembly machine in this embodiment includes a fixed transmission frame 10, a movable transmission frame 20, a combined conveyor 30 and a push-pull bridge erecting machine 40, and the fixed transmission frame 10 is installed on the barrel end of the ball mill The outer side is provided with a lifting bracket 11 and a loading and unloading rocker arm 12. The movable transmission frame 20 is installed in the inner cavity of the ball mill cylinder and is provided with a lifting and moving bracket 21, a telescopic positioning bracket 22 and an assembly rocking arm 23. The moving bracket 21 is provided with laterally moving rollers 210, and the combined conveyor 30 is formed by interconnecting multi-section roller transfer boxes 31 and erected between the fixed transfer frame 10 and the movable transfer frame 20. The end and side of 31 are respectively provided with bolt-type movable joint 32 and tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com