Double-ball-pair two-freedom-degree inclinable working table

A workbench and degree of freedom technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large vertical size, insufficient rigidity of the workbench, limited capacity, etc., and achieve accurate and controllable inclination angle , the contact area is large, the effect of reducing the space in the vertical direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

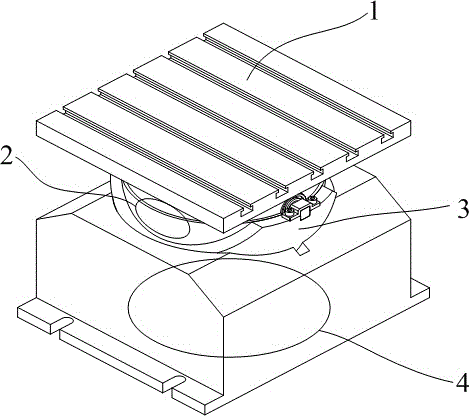

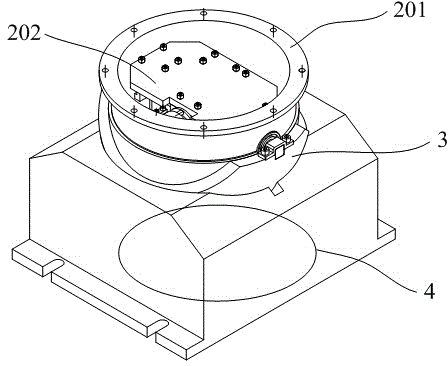

[0026] The present invention is a high-rigidity double-ball pair two-degree-of-freedom tiltable workbench, which consists of four parts: a workpiece fixing table 1, an upper table 2, a double-ball middle table 3, and a lower table 4.

[0027] See figure 1 , figure 2 , the workpiece fixing table 1 is a fixing plate with a T-shaped groove, which is used to cooperate with T-shaped bolts to fix the workpiece. The workpiece fixing table 1 and the upper ball sub-housing 201 of the upper table 2 are fixedly connected by screws.

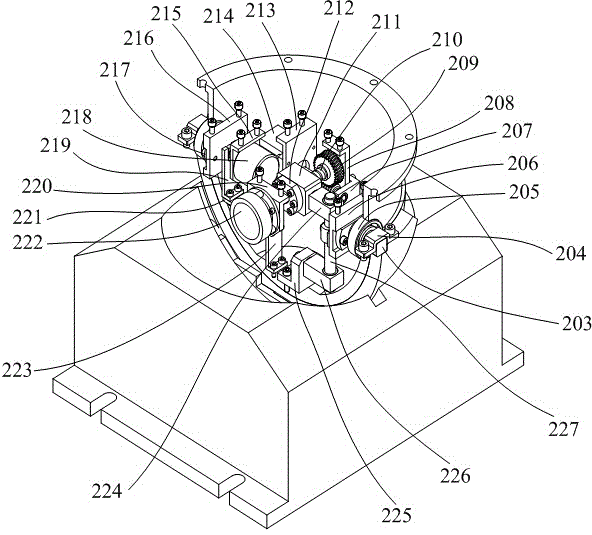

[0028] See Figure 1 ~ Figure 3 The left and right rotation shafts 217 and the right rotation shaft 203 respectively equipped with bearings 205 are installed in the left and right holes of the upper ball sub-housing 201 of the upper stage 2 part, and the left rotation shaft 217 and the right rotation shaft 203 pass through the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com