PFA shrinkage-prevention injection molding device

An anti-shrinkage, injection molding machine technology, applied in the field of valve injection molding, to achieve good injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is further described:

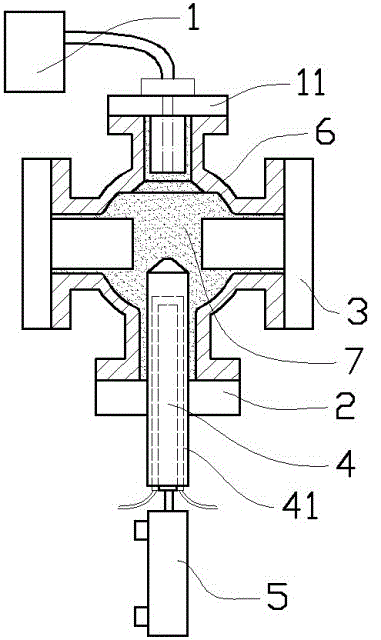

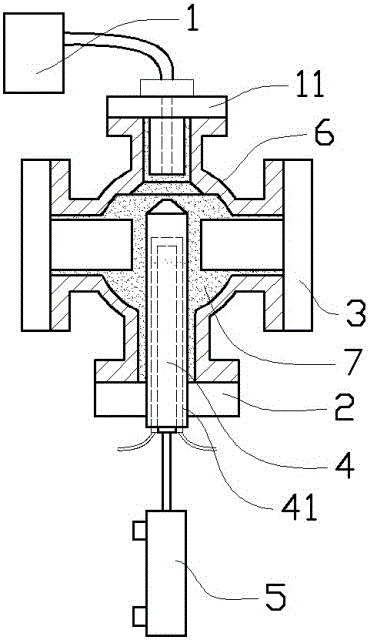

[0017] Such as figure 1 and figure 2 As shown in the embodiment, the PFA anti-shrinkage injection molding device is mainly used in the injection molding production process of the valve body 6 of the cone valve. The valve body 6 has four symmetrical openings up, down, left, and right. It includes an injection molding machine 1, a lower flange 2, Side head 3, telescopic shaft 4, cylinder 5; the injection molding machine 1 is fixed on the upper opening of the valve body 6 through the injection molding head 11. In this embodiment, the injection molding machine 1 usually uses granular PFA as the veteran, and heats and melts Afterwards, it is sent to the injection head 11, and then the melted PFA raw material 7 is sent into the valve body 6 by the injection head 11. Described lower flange 2 is assembled on the lower opening of described valve body 6, and described valve body 6 is fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com