Aluminium-foil paper conveying terminal positioning device

A technology of terminal positioning and aluminum foil paper, which is applied in the directions of transportation packaging, transportation and packaging, and packaging material feeding devices, etc., can solve the problems of increased shutdown rate, decreased equipment operation rate, and increased consumption of aluminum foil paper, etc., to save manufacturing costs , the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

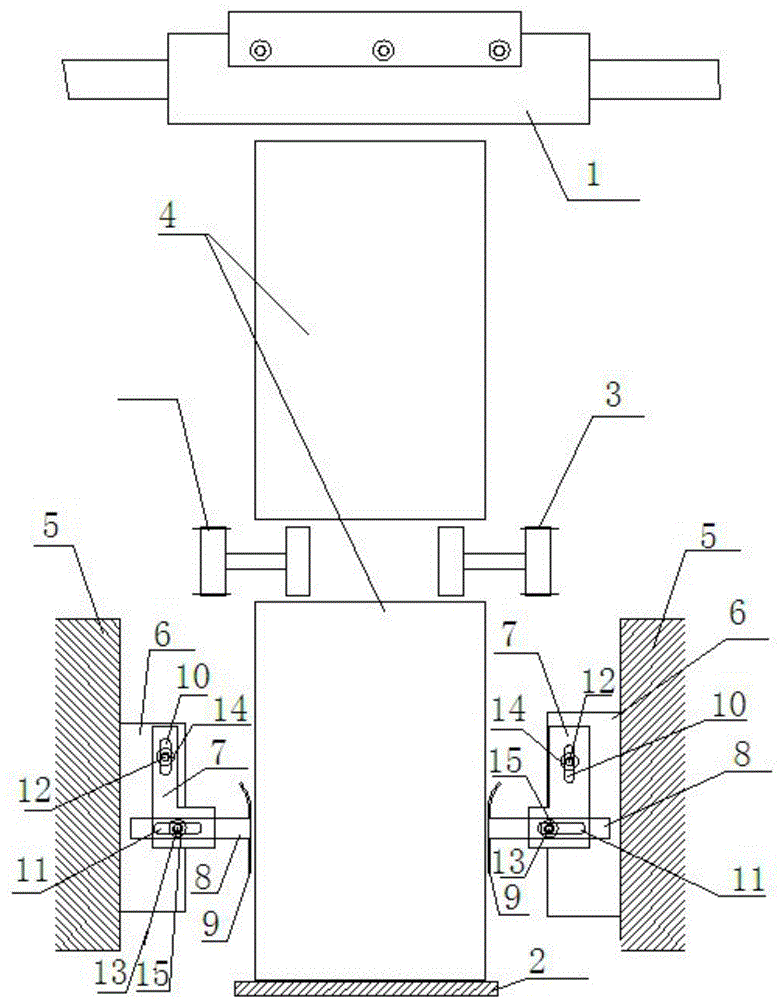

[0014] Such as figure 1 As shown, the present invention provides an aluminum foil conveying terminal positioning device, which includes an aluminum foil output end 1, a conveying wheel 3, and a lower paper arrival reference 2 that cooperates from top to bottom to form an aluminum foil output path. A cantilever 6 is provided on the base 5 of the machine, and a baffle mount 7 is symmetrically arranged on the two cantilevers 6, a baffle bracket 8 is arranged on the baffle mount 7, and a baffle 9 is arranged at one end of the baffle bracket 8, Both baffles 9 are arranged at one end of the baffle bracket close to the output path of the aluminum foil paper. The height of the two baffles 9 is the same, parallel to each other and parallel to the conveying direction of the conveying wheel 3, and the two baffles 9 are located between the convey...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap