Sapphire single growth furnace heat preservation device capable of conveniently regulating temperature gradient

A technology for adjusting temperature and heat preservation device, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of easy deformation of materials, change of temperature gradient, increase production cost, etc., to enhance heat preservation effect, reduce power consumption, The effect of improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

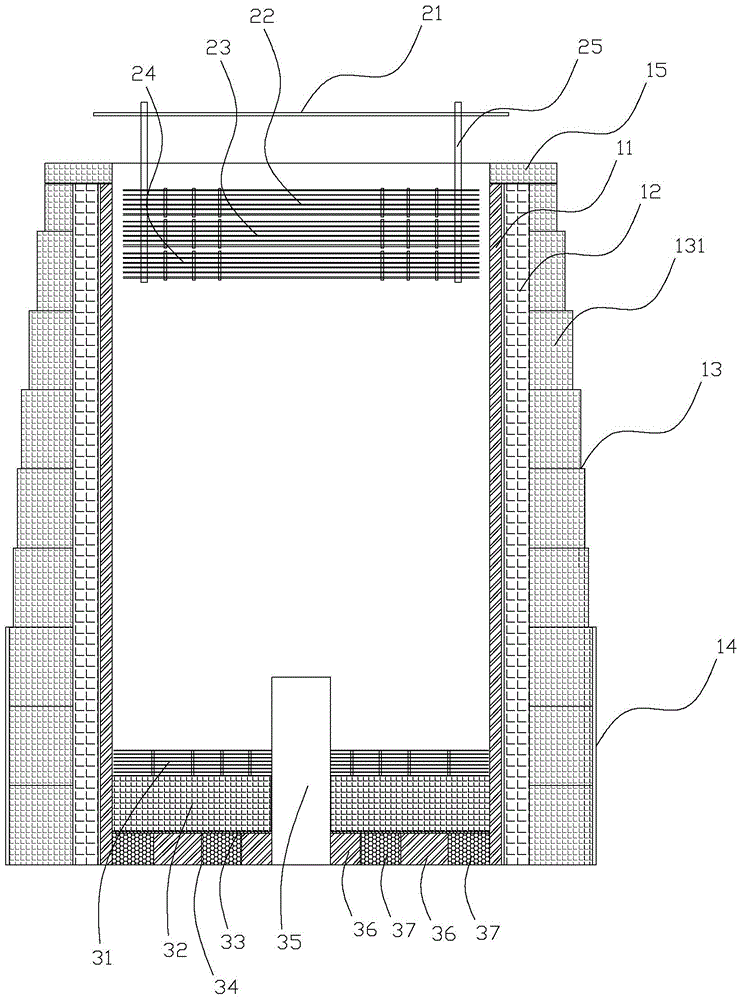

[0028] Such as figure 1 The shown sapphire single growth furnace heat preservation device for convenient adjustment of temperature gradient includes an upper heat shield, a side temperature control system, and a lower heat preservation system. The side walls of the side temperature control system are set with different thicknesses in the height direction to adjust Temperature gradient in the growth furnace.

[0029] The side temperature control system includes a tungsten barrel 11, a heat preservation barrel 12, a temperature adjustment barrel 13, and a fastening barrel 14, and the tungsten barrel 11, the heat preservation barrel 12, the temperature adjustment barrel 13, and the fastening barrel 14 are sequentially integrated from the inside to the outside. The side temperature control system also includes a thermal insulation cover plate 15,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap