Control method for automatic memory polishing of rail grinding train main line

A technology for grinding trains and automatic memory. It is applied in electrical program control, program control in sequence/logic controllers, tracks, etc. It can solve the problems of increasing the labor intensity of operators, affecting the grinding effect, and increasing the grinding time. The effect of simple operation, high grinding accuracy and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

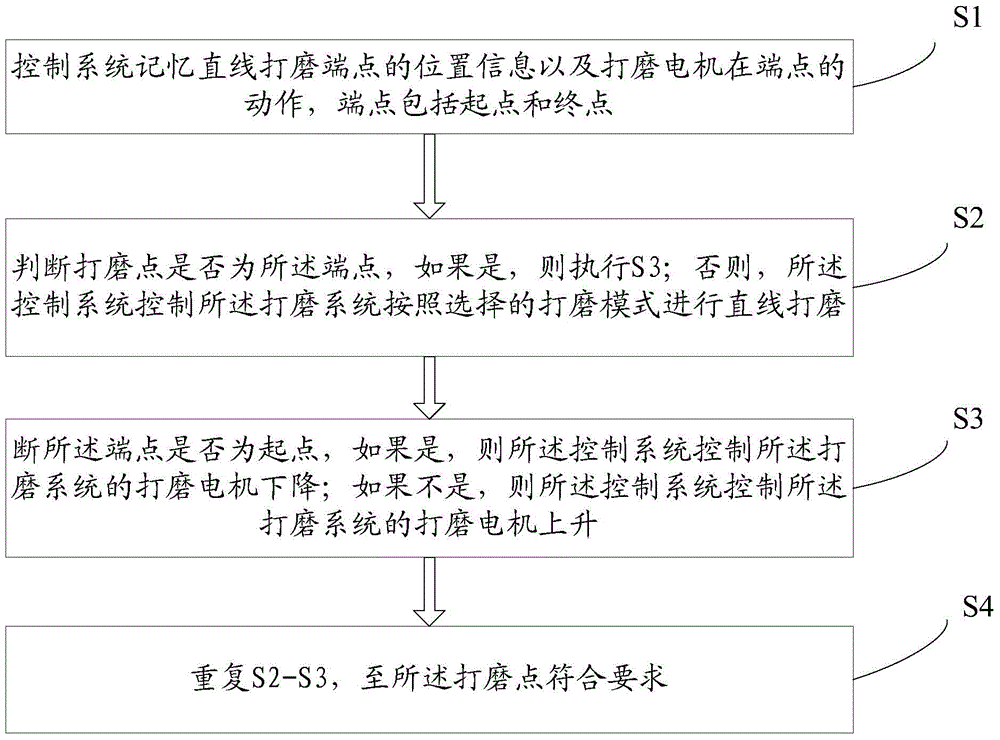

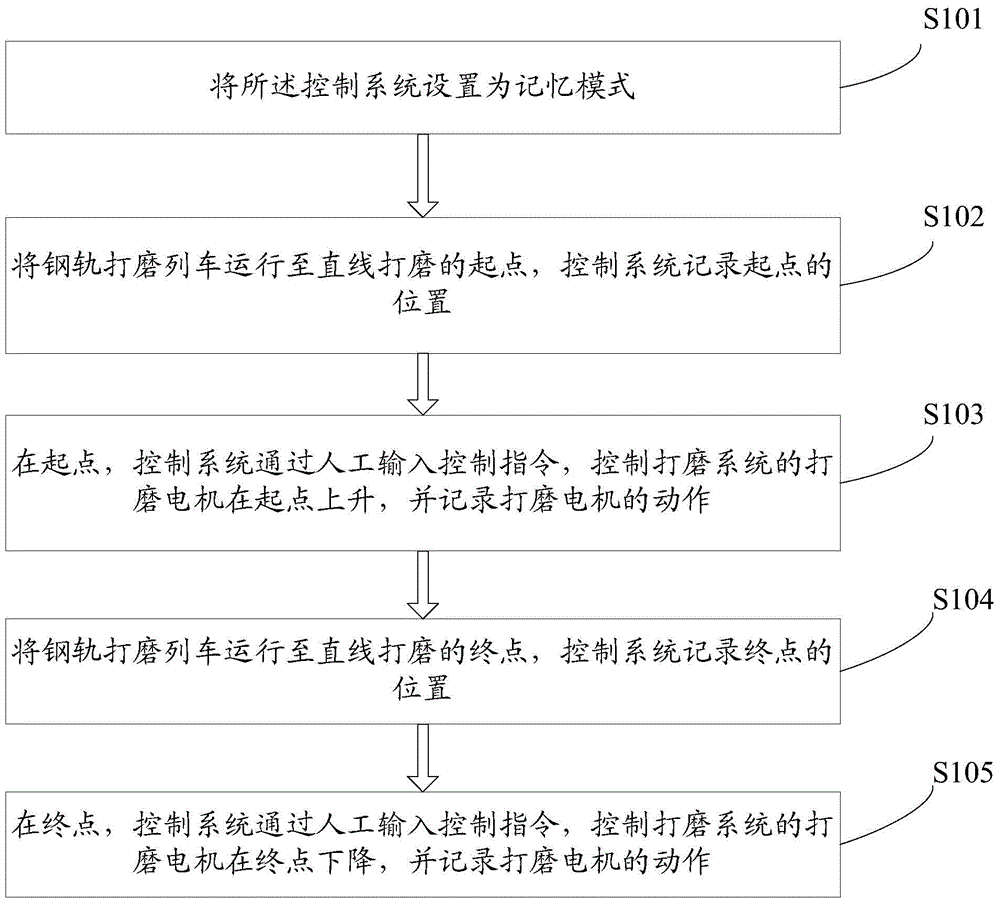

[0047] Such as figure 2 As shown, S1 includes the following steps:

[0048] S101, setting the control system to a memory mode;

[0049] S102, running the rail grinding train to the starting point of the linear grinding, and the control system records the position of the starting point;

[0050] S103, at the starting point, the control system controls the grinding motor of the grinding system to rise at the starting point by manually inputting a control command, and records the movement of the grinding motor;

[0051] S104, running the rail grinding train to the end point of the straight line grinding, and the control system records the position of the end point;

[0052] S105, at the end point, the control system controls the grinding motor of the grinding system to descend at the end point by manually inputting a control command, and records the action of the grinding motor.

[0053] By adopting the above method, the memory of the position information of the starting poin...

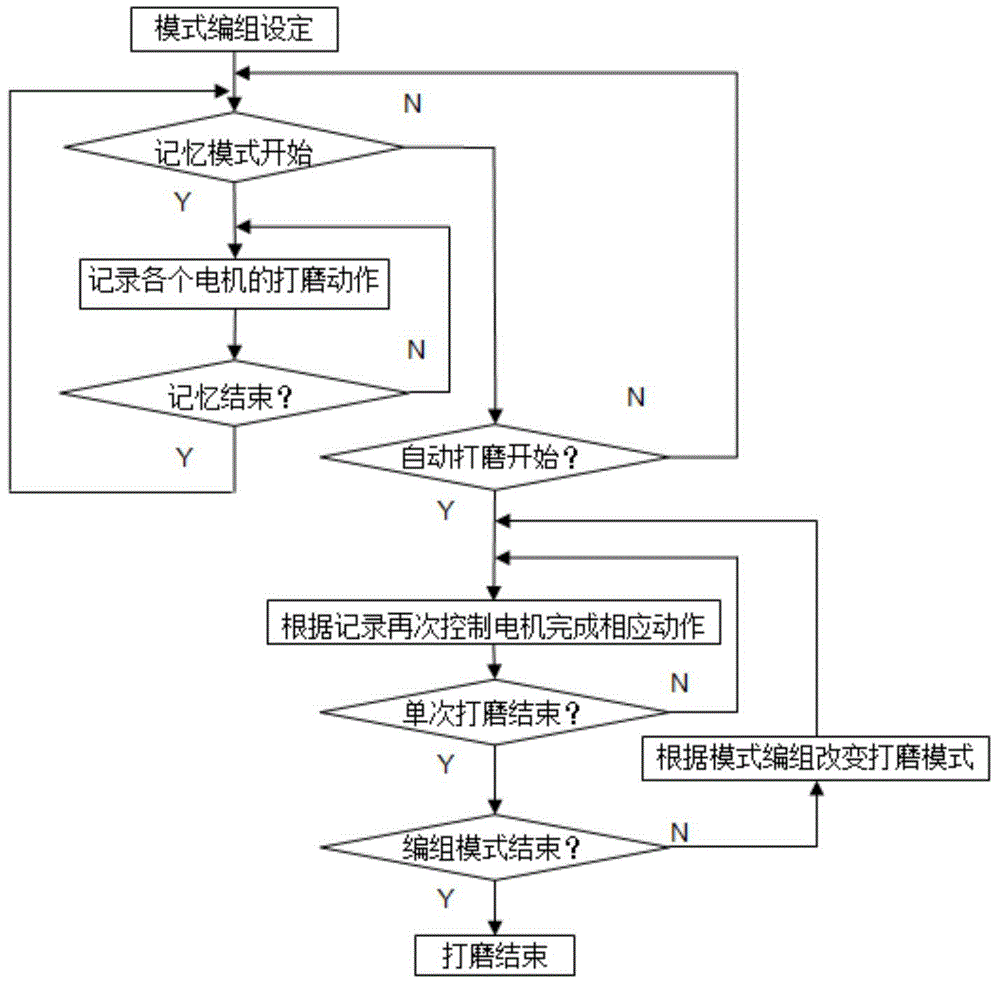

Embodiment 3

[0063] Such as Figure 4 As shown, the control method for automatic memory grinding of rail grinding train main line provided by the embodiment of the present invention can adopt a control system with the following structure, including: a main CPU unit 1, a slave CPU unit 2 and a switch 3, and the main CPU unit 1 is arranged on In the driver's cab 4 of the subway rail grinding train, the slave CPU unit 2 is arranged in the grinding control cabinet 5 of the subway rail grinding train, and the slave CPU unit 2 and the main CPU unit 1 are connected by Ethernet through the switch 3, and the slave CPU unit 2 and the The switch grinding device 6 of the subway rail grinding train is connected to the data.

[0064] The actual working process of the control system is: (1) The master CPU unit transmits control instructions to the slave CPU unit through Ethernet; Action execution instructions for control; (3) collect and obtain state data from the detection mechanism of the grinding sys...

Embodiment 4

[0074] Such as Figure 5 Shown, in the embodiment of the present invention, main CPU unit 1 can comprise main communication module 8 and PLC host 9, and PLC main unit 9 is connected with main communication module 8 data; From CPU unit 3 can comprise from communication module 10 and PLC slave 11 , the PLC slave 11 is connected to the data from the communication module 10, and the PLC slave 11 is connected to the switch grinding device 6; the master communication module 8 and the slave communication module 10 are connected through the switch 3 via Ethernet.

[0075] In the actual working process of the control system, the main communication module and the slave communication module are mainly used for data transmission, the PLC host is mainly used for information memory, status information display, receiving and sending of control instructions, and the PLC slave is mainly used for Send execution instructions to the grinding system to control the grinding system to complete the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com