Incision slitting disk grinding machine

A grinding machine and saw disc technology, which is applied to metal sawing equipment, tool dressing of sawing machine devices, metal processing equipment, etc. Simple, guaranteed grinding angle, ingenious effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

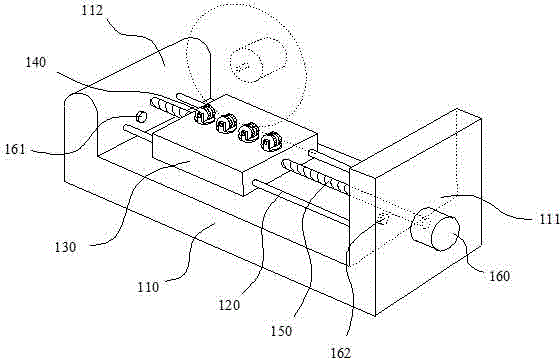

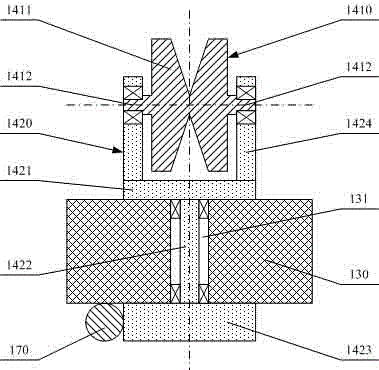

[0015] The invention provides a cutting saw disc grinder, such as figure 1 As shown, the cutting saw disk grinder includes a base support 110, on which two slide rails 120 and a screw rod 150 are horizontally erected, and the screw rod 150 is located between the two slide rails 120 and connected to the two slide rails. Parallel to each other; a sliding block 130 is slidably sleeved on two slide rails 120 through its two sides, and the middle part of the sliding block 130 is transversely provided with a screw through hole for the screw 150 to pass through, and the screw through hole has a 150 threaded sections, so that the sliding block 130 can slide along the slide rail 120 under the drive of the rotation of the screw rod 150; the two ends of the two slide rails 120 are respectively fixed on both sides of the base bracket 110, and one side has a block that can block the sliding block. 130 slides out of the stop wall 111 of the slide rail, and the other side has a block 112 cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com