Dust removing method

A technology of dust and dust hood, applied in cleaning methods, road cleaning, construction, etc., can solve problems such as affecting the appearance and travel of other vehicles, increasing the burden on urban drainage systems, and easily blocking sewer pipes, and can solve the problems of primary and secondary Dust, simple and ingenious design, eliminate the effect of primary dust and secondary dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

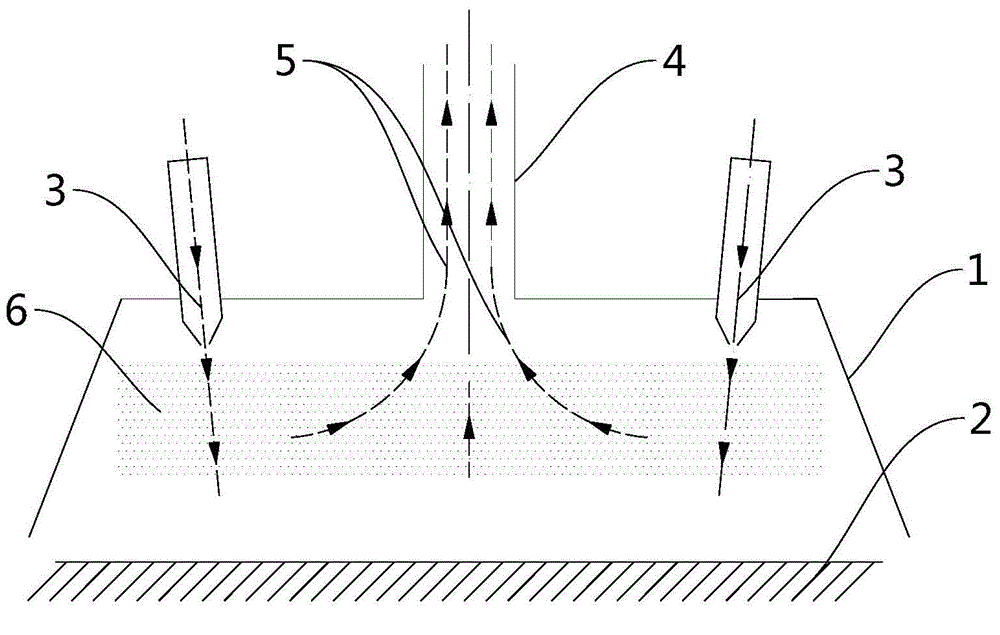

[0022] Such as figure 1 Shown, the dedusting method that the present invention designs is characterized in that comprising the following steps:

[0023] 1. Use the dust collection cover 1 to cover the area 2 to be dust collected;

[0024] 2. From the outside of the dust collection hood 1 to the area 2 covered by the dust collection hood 1, multiple compressed air streams 3 are sprayed to make the dust particles 6 in the dust collection hood 1 into a suspended state;

[0025] 3. A negative pressure pipeline 4 communicating with the inside of the dust collection hood 1 is provided inside the dust collection hood 1, and the dust particles 6 in a suspended state in the dust collection hood 1 are removed from the dust collection hood by the negative pressure airflow 5 passing through the negative pressure pipeline 4 1 Internal suction collection device.

[0026] Preferably, the negative pressure air flow 5 and the multiple compressed air flows 3 work synchronously.

[0027] Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com