Intelligent wall brushing machine driven by crank sliding block and capable of adjusting angles of rolling brushes in fixed-step-size mode

A technology of intelligent wall brushing machine and crank slider, which is applied in the direction of construction and building construction, can solve the problems of wasting paint, paint material, cost increase, and paint waste, so as to save paint, increase the speed of wall painting, reduce the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

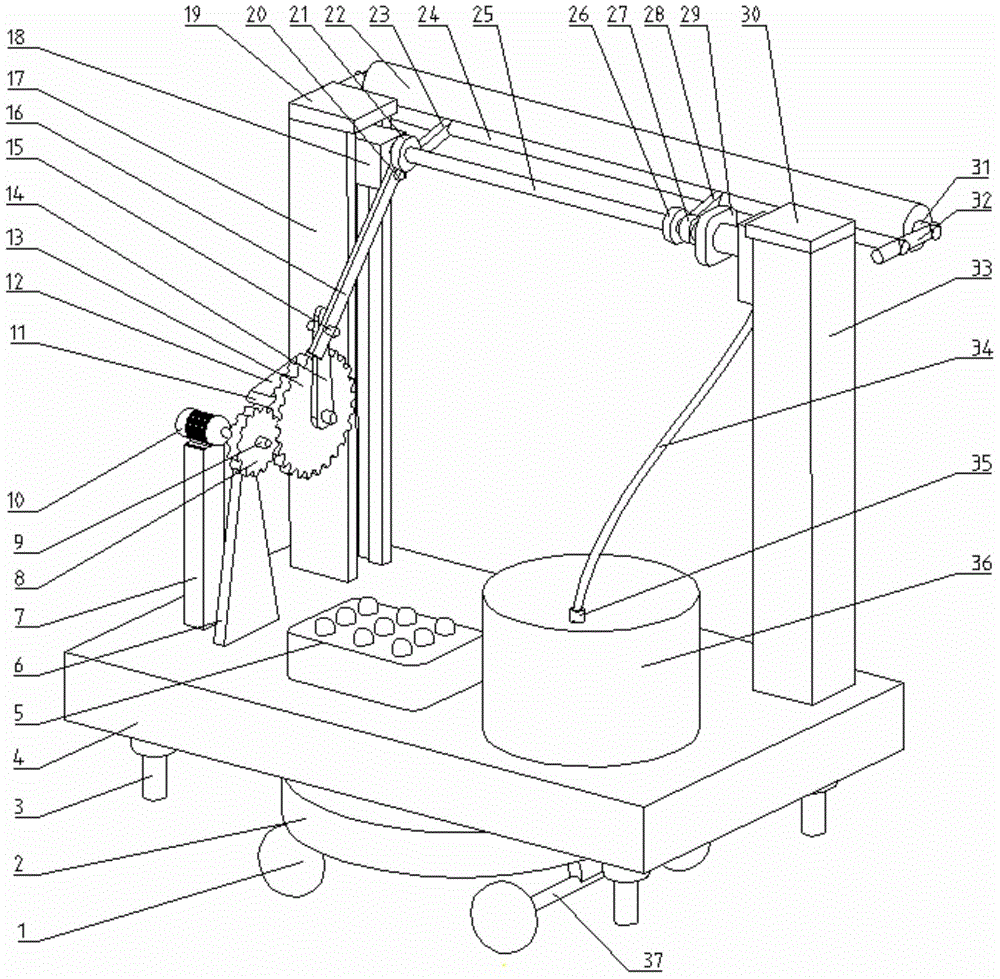

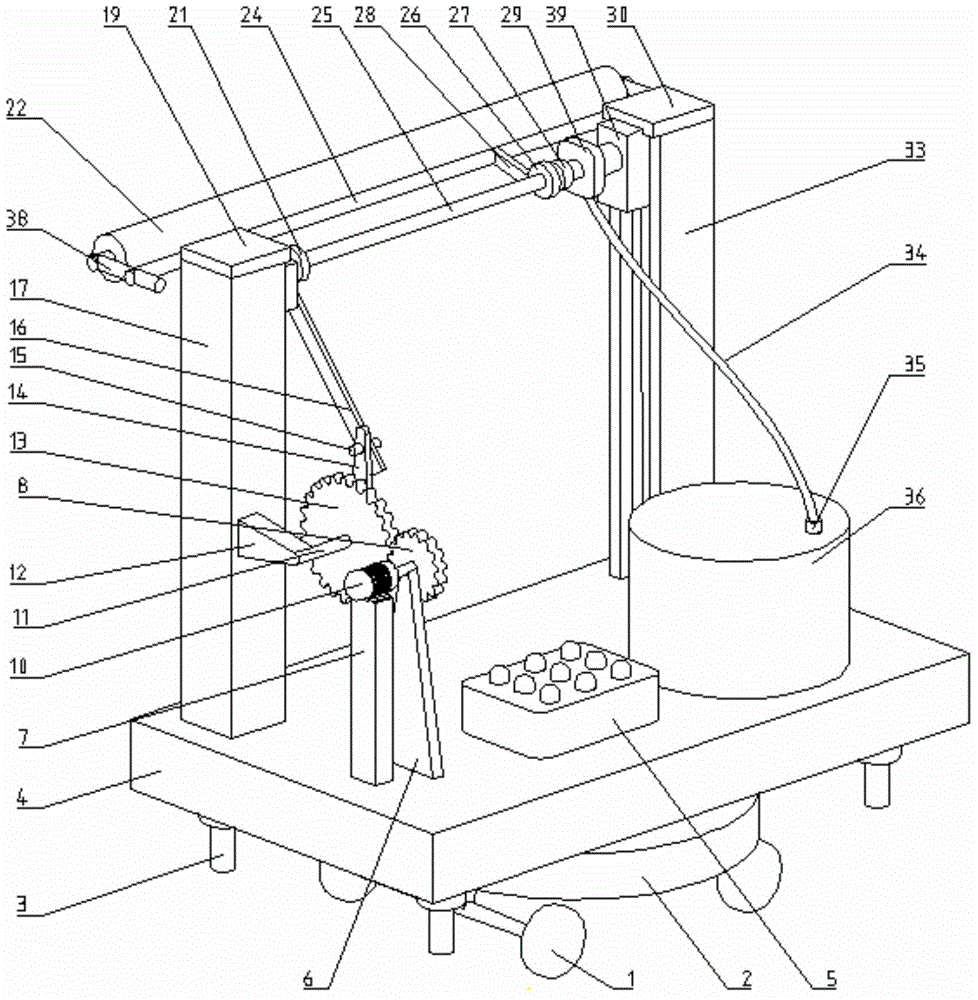

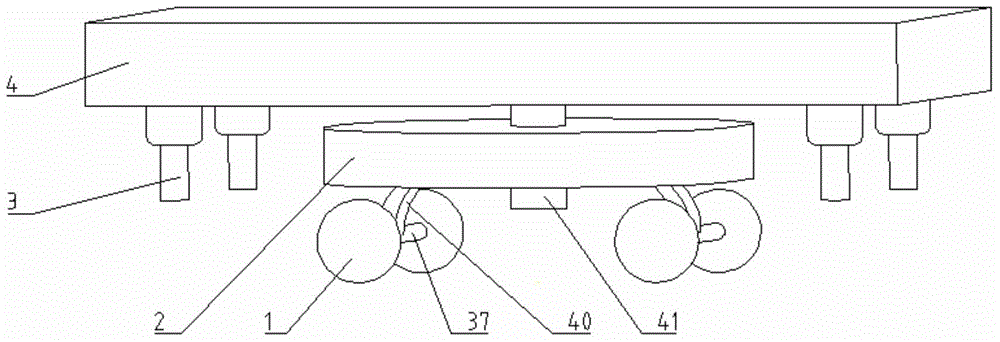

[0017] Below in conjunction with accompanying drawing, the smart wall brushing machine of the present invention, which is driven by the crank slider and has a fixed-step length, and the angle can be adjusted, will be further described.

[0018] Such as figure 1 and figure 2 As shown, two symmetrically arranged left uprights 17 and right uprights 33 are fixed on the base 4, and the left uprights 17 and right uprights 33 are respectively provided with slidingly fitted left sliders 18 and right sliders 39 on the opposite inner sides. The motor 10 is installed on the second fixed block 7, the active fixed gear 8 is installed on the first shaft 9, the first shaft 9 is installed on the first fixed block 6 through a bearing, and the second fixed block 7 and the first fixed block 6 are fixed On the base 4, the first shaft 9 is connected with the output shaft of the motor 9 through a coupling; On the three fixed blocks 12, the third fixed block 12 is fixed on the column, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com