Mining environment-reconstructing mobile pumping filling artificial pillar shrinkage mining method

An artificial ore pillar, mobile technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of high mining cost, high ore loss rate, roof falling in goaf, etc., to solve the problem of high mining loss rate , the effect of improving resource recovery rate and reducing mining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

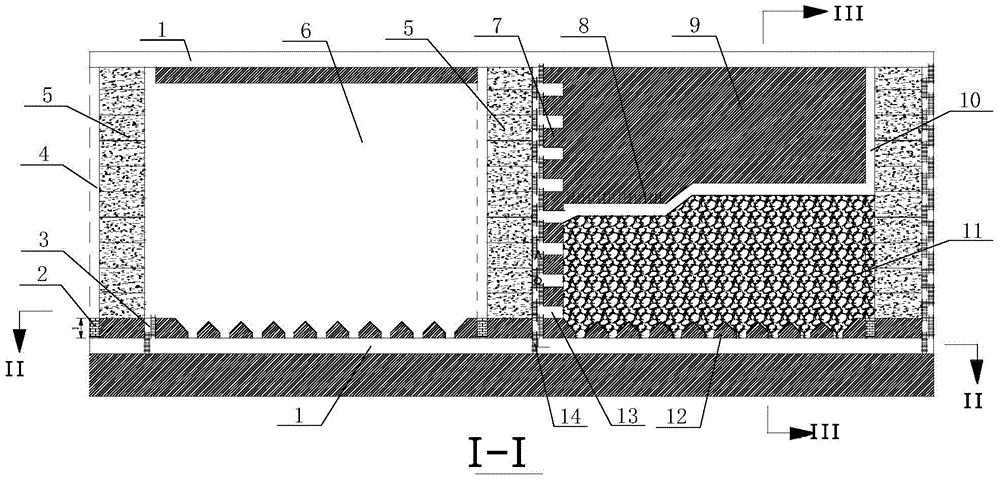

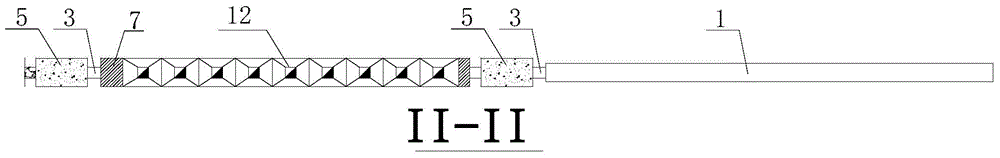

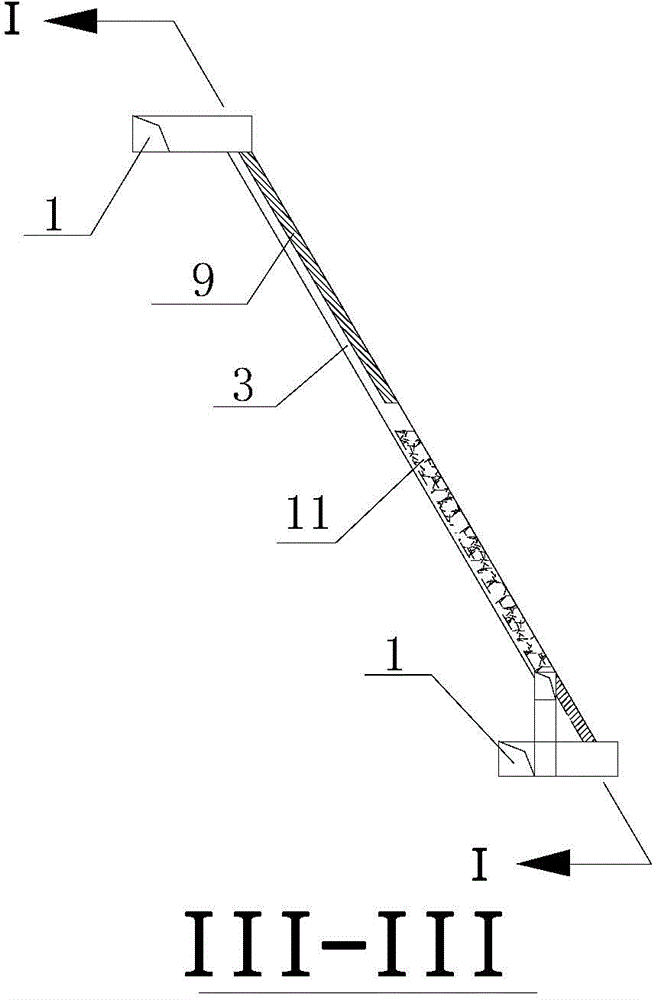

[0014] see figure 1 , figure 2 and image 3 , in the picture: 1. Middle transportation roadway, 2. Artificial false bottom, 3. Pedestrian inclined shaft, 4. Slide shaft, 5. Artificial pillar, 6. Goaf, 7. Reserved pillar, 8. Blasting hole, 9. Unmined ore body, 10. Stope return air shaft, 11. Caving ore, 12. Funnel, 13. Pedestrian contact roadway, 14. Pedestrian ladder, when mining inclined or steeply inclined thin ore body without filling system, according to mining The ore body is divided into ore houses and pillars along the strike direction. First, the upward layered filling mining technology is used to mine the ore pillars, and the mobile pumping filling system is used for layered filling operations. Inclined shafts and slide shafts are used to reconstruct the mining environment; after the pillars are mined and filled to form artificial pillars, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com