Quick opening-closing pneumatic system of gas-saving low-noise valve

A fast switch and pneumatic system technology, applied in the field of pneumatic systems, can solve the problems of affecting the service life of air compressors, high air noise in air consumption, and affecting fitability, etc., and achieve low instantaneous air supply requirements, reduced air noise, The effect of air consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

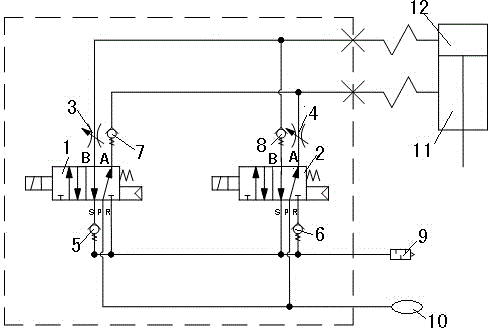

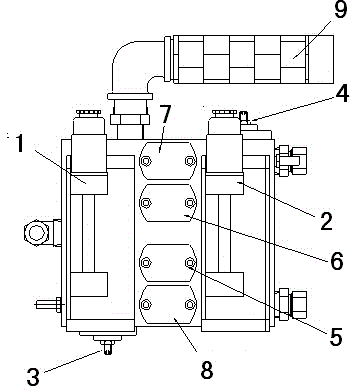

[0014] like figure 1 As shown, a gas-saving and low-noise valve quick switch pneumatic system includes two two-position five-way electromagnetic reversing valves A and B, four check valves with different opening pressures and two throttle valves, of which the check valve And throttle valve adopts cartridge valve, and the whole system is realized in the form of integrated valve block.

[0015] The air inlet and outlet of the rodless chamber 12 of the cylinder are connected to the air source 10 through the first throttle valve 3 and the two-position five-way electromagnetic reversing valve A1, or through the first throttle valve 3 and the two-position five-way electromagnetic reversing valve A1 It communicates with the muffler 9 with the first one-way valve 5; the other way communicates with the muffler 9 through the fourth one-way valve 8 and the two-po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com