Drive and control circuit for fast solenoid valve

A technology for driving control circuits and solenoid valves, applied in the direction of valve operation/release devices, valve details, valve devices, etc., can solve problems such as unsatisfactory control accuracy and low stability, and achieve improved response speed, control accuracy, and power The effect of reducing power consumption and reducing friction hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Combined with the test of this circuit in an electronic controller project, the implementation mode and use effect of this circuit will be explained in detail.

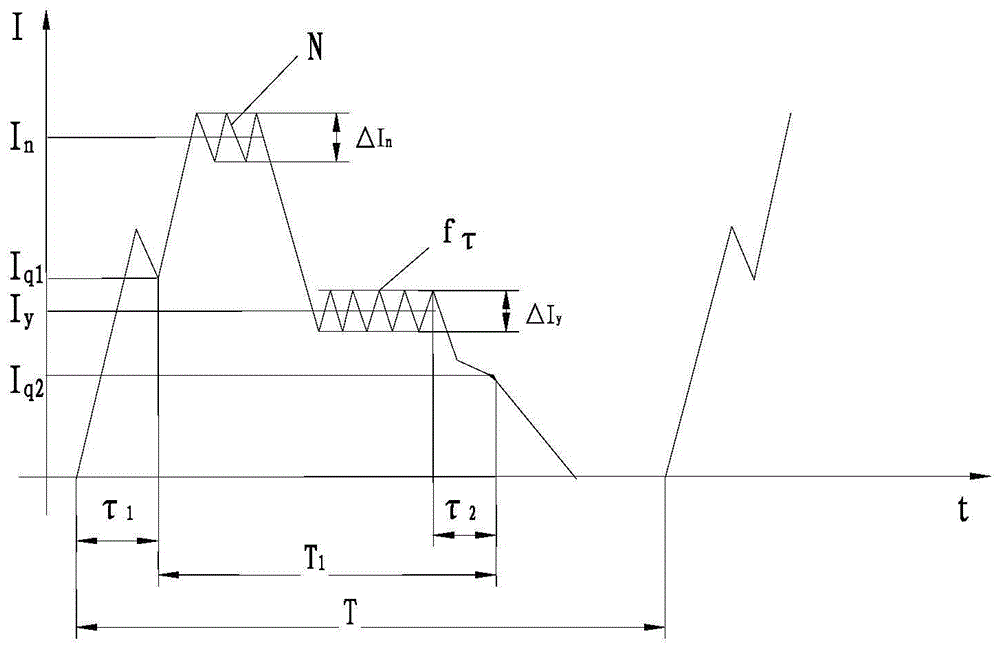

[0043] The RST1 and RST2 signals that control the general-purpose timer D1 are generated by the event manager of the DSP. The two control signals RST1, RST2 and the final pulse waveform are as follows: Figure 6 As shown, 10ms to 40ms in the figure corresponds to a complete pulse cycle.

[0044] RST1 and RST2 are respectively controlled by peripheral function pins PWM1 and PWM3 belonging to the DSP event manager. These two control signals are generated by comparison unit 1 and comparison unit 2, and use general-purpose timer 1 together. 10-40ms is general-purpose timer 1 A counting period of the counting cycle, the comparison match of comparison unit 1 is generated at 20ms, and RST1 is flipped; the comparison match of comparison unit 2 is generated at 30ms, and RST2 is flipped; the period match of general-purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com