Liquid carbon dioxide supplementing and supercharging device

A technology of liquid carbon dioxide and carbon dioxide, which is applied to equipment loaded into pressure vessels, gas/liquid distribution and storage, container filling methods, etc., can solve the impact on the service life of electrical components, the impact of pressure fluctuations on the accuracy of blowing agent metering injection systems, Problems such as pressure fluctuations at the outlet of the pressurized buffer tank, to reduce maintenance times and costs, reduce change sensitivity, and overcome large outlet pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

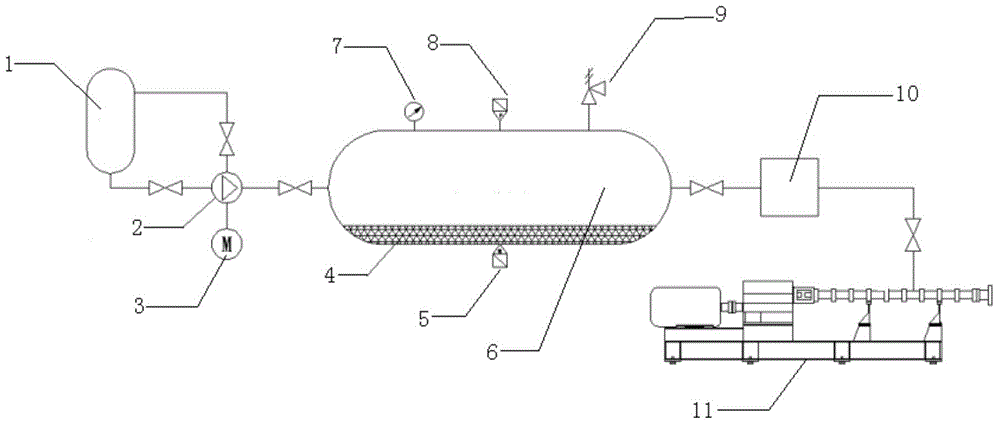

[0014] Such as figure 1 , as shown in the structure schematic diagram of the present invention, a kind of liquid carbon dioxide replenishment pressurization device of this scheme comprises carbon dioxide storage tank 1, reciprocating booster pump 2, pressurization buffer tank 6, foaming agent metering injection system 10 and extruding machine 11, the top and bottom ends of the carbon dioxide storage tank 1 are respectively connected to the reciprocating booster pump 2 through pipelines, the reciprocating booster pump 2 is provided with a hydraulic motor 3, and the double booster pump 2 is connected to the booster buffer tank 6 through pipelines connection, the top of the pressurized buffer tank 6 is provided with a pressure sensor 8, the two sides of the pressure sensor 8 are respectively provided with a pressure sensor 8 and a safety valve 9, the inner bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com