A charging device for high-viscosity liquid charge

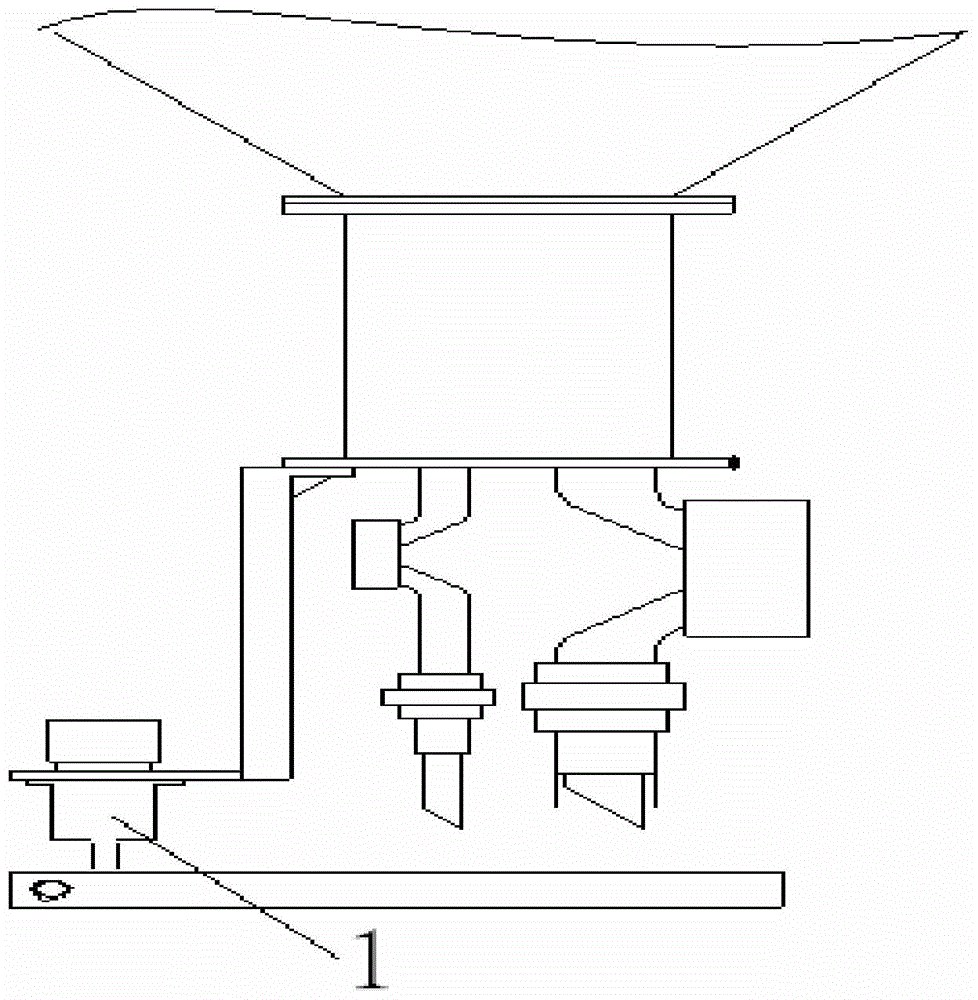

A material receiving device and high-viscosity technology, which is applied in the field of solid rocket motor charging, can solve the problems of practical application in the field of liquids that have not yet flowed, and achieve the effects of avoiding occupational health hazards, saving time, and ensuring weighing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

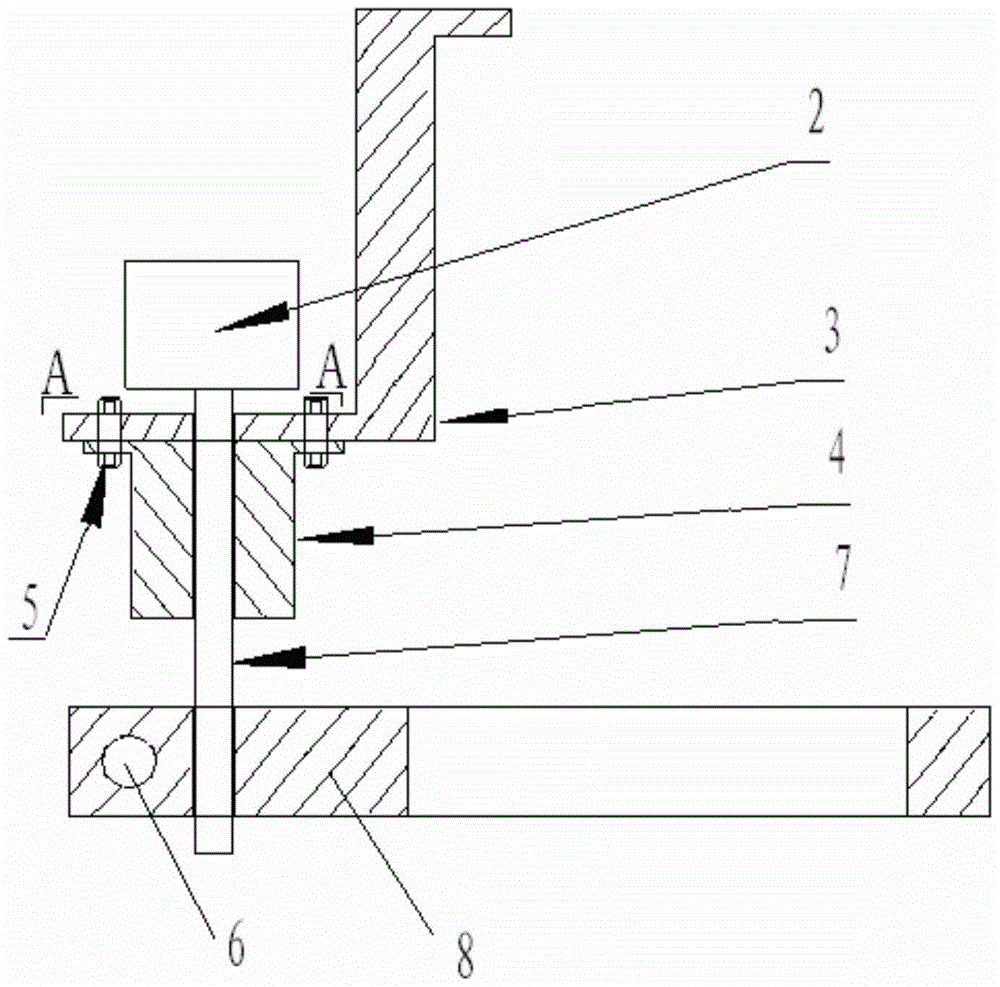

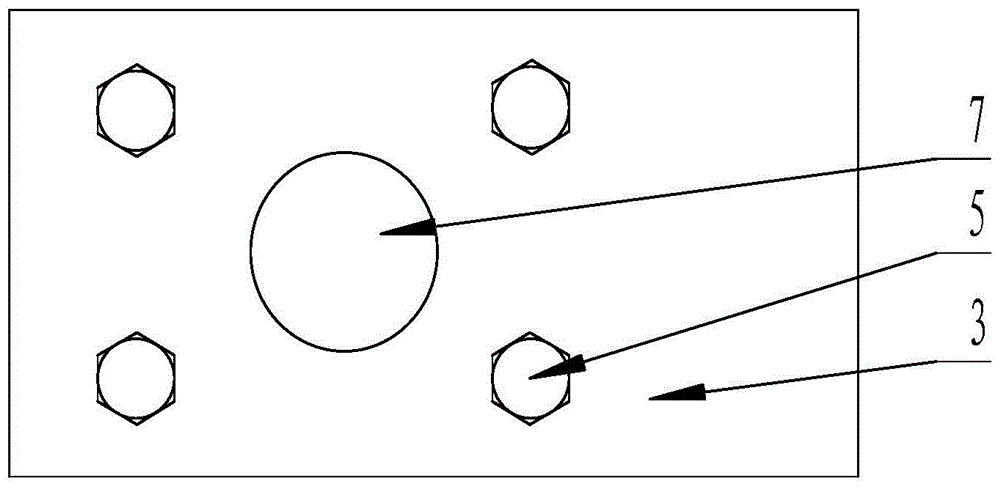

[0019] This embodiment is an auxiliary device for automatic weighing of mucus—a feeding device, which includes a rotary cylinder 2 , a mounting plate 3 , a shaft sleeve seat 4 , a shaft 7 and a rotary basin frame 8 . The mounting plate 3 is the carrier of this embodiment: the bushing seat 4 is fixed on the lower surface of the mounting plate 3 through a flange, and the center hole of the bushing seat 4 is concentric with the shaft through hole on the mounting plate 3 . The rotary cylinder 2 is installed on the upper surface of the mounting plate 3 ; the output end of the rotary cylinder 2 is fixedly connected with one end of the shaft 7 . The other end of the shaft 7 passes through the shaft hole on the mounting plate 3 and the sleeve seat 4 fixed on the lower surface of the mounting plate, is put into the shaft hole on the rotating basin frame 8, and is fixedly connected with the rotating basin frame 8 .

[0020] There is a connecting plate on one side of the mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com