Method for automatically calibrating scanning type infrared temperature measuring system deviating from preset monitoring point

A technology of infrared temperature measurement and calibration method, which is applied in the direction of measuring devices, radiation pyrometry, optical radiation measurement, etc., can solve the problems of point thermometer deviation and temperature measurement accuracy drop, so as to avoid the consumption of manpower and material resources and improve Efficiency and accuracy, solving the effect of deviation from preset monitoring points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

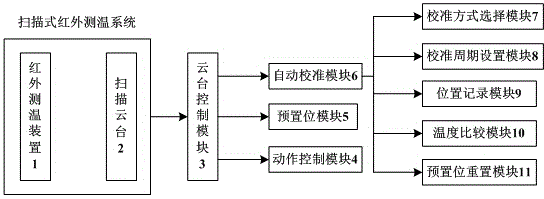

[0019] Such as figure 1 The structural block diagram of the scanning infrared temperature measurement system is shown, and the scanning infrared temperature measurement system is composed of two parts: an infrared temperature measurement device 1 and a scanning cloud platform 2 . The pan-tilt control module 3 is composed of a motion control module 4 , a preset position module 5 and an autonomous calibration module 6 . Among them, the autonomous calibration module 6 is composed of a calibration mode selection module 7 , a calibration cycle setting module 8 , a temperature comparison module 9 , a position recording module 10 , and a preset position reset module 11 .

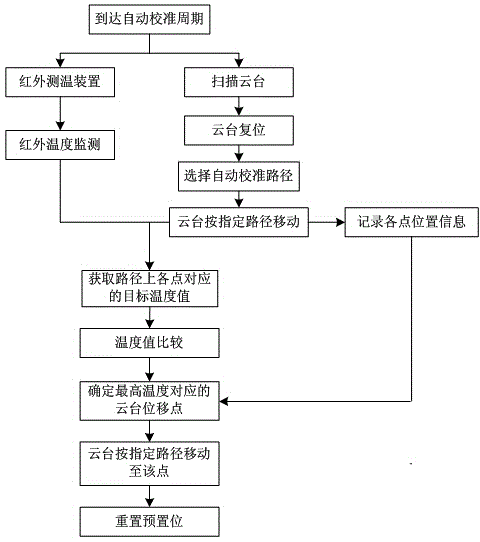

[0020] After the gimbal runs for a long time, the mechanical deformation of the fixed end (such as thermal expansion and contraction) will cause a short-distance and small-angle deviation between the gimbal and the preset position. However, due to factors such as the insulation conditions of electrical equipment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com