Micro-differential pressure measuring device for detecting airflow of pipeline

A technology for detecting pipes and measuring devices, applied in the field of detection, can solve the problems of high cost, poor repeatability, unstable airflow in exhaust pipes, etc., and achieve the effects of simple structure, high measurement accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

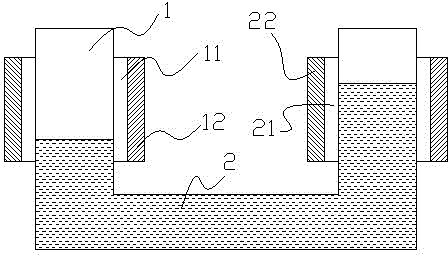

[0011] Such as figure 1 As shown, a differential pressure measurement device for detecting pipeline airflow includes a U-shaped tube 1 loaded with a magnetic liquid 2, one end of the U-shaped tube 1 is wound with a first inner coil 11, and the first inner coil 11 is wound outside The first outer coil 12 coaxial with it, the other end of the U-shaped pipe 1 is wound with a second inner coil 21, the second inner coil 21 is wound with a second outer coil 22 coaxial with it, the first inner coil 11 and the second inner coil 11 The two inner coils 21 are connected in series to the AC input end, and the first outer coil 12 and the second outer coil 22 are reversely connected in series to serve as data output ends.

[0012] Principle of the present invention is:

[0013] Assuming that the turns of the first inner coil 11 and the second inner coil 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com