Vertical driving mechanism for slide rail testing machine

A driving mechanism and testing machine technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of low production efficiency, large space occupation, and dense personnel, so as to reduce input costs and improve The effect of work efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

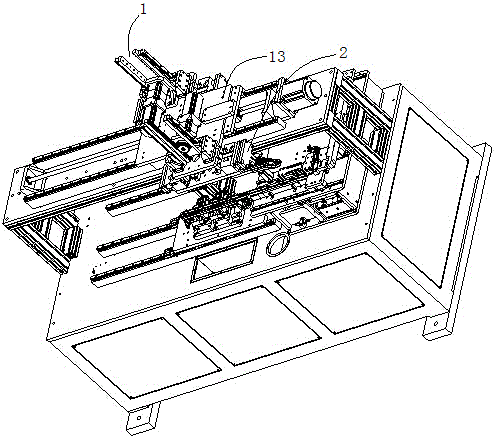

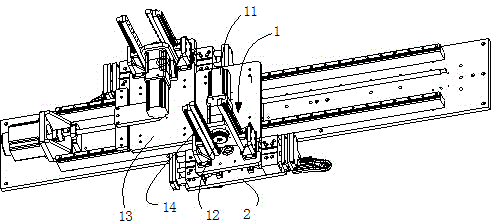

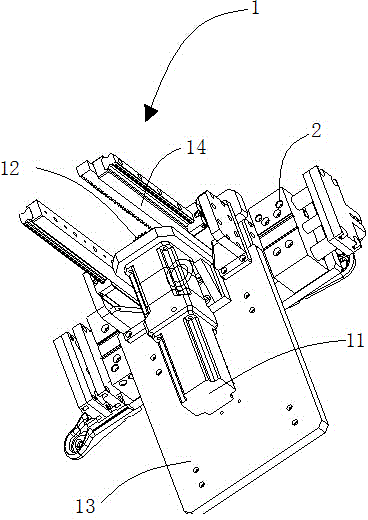

[0012] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0013] like Figure 1 to Figure 3 As shown, in the vertical drive mechanism of a slide rail testing machine disclosed in the present invention, the vertical drive mechanism 1 for vertically moving the pressing mechanism 2 includes a second motor 11 and a gear 12 connected to the second motor 11 , the drive plate 13 and the guide rail 14, the gear 12 is fixedly connected with the second motor 11, the gear 12 is fixed on the drive plate 13 by a fixture, the guide rail 14 is perpendicular to the drive plate 133 and is fixedly connected with the pressing mechanism, and the guide rail 14 is provided with The teeth meshed with the teeth on the gear 12, the second motor 11 drives the gear 12 to rotate forward and reverse, and the driving guide rail 14 moves vertically up and down with the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com