Full-automatic frequency modulation machine for columnar crystal

A technology of columnar crystals and frequency modulation machines, which is applied in the direction of grinding drive devices, grinding machine parts, grinding machines, etc., can solve the problems of reducing the labor intensity of the operator, high labor intensity, and low production efficiency, so as to improve work efficiency and Product qualification rate and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

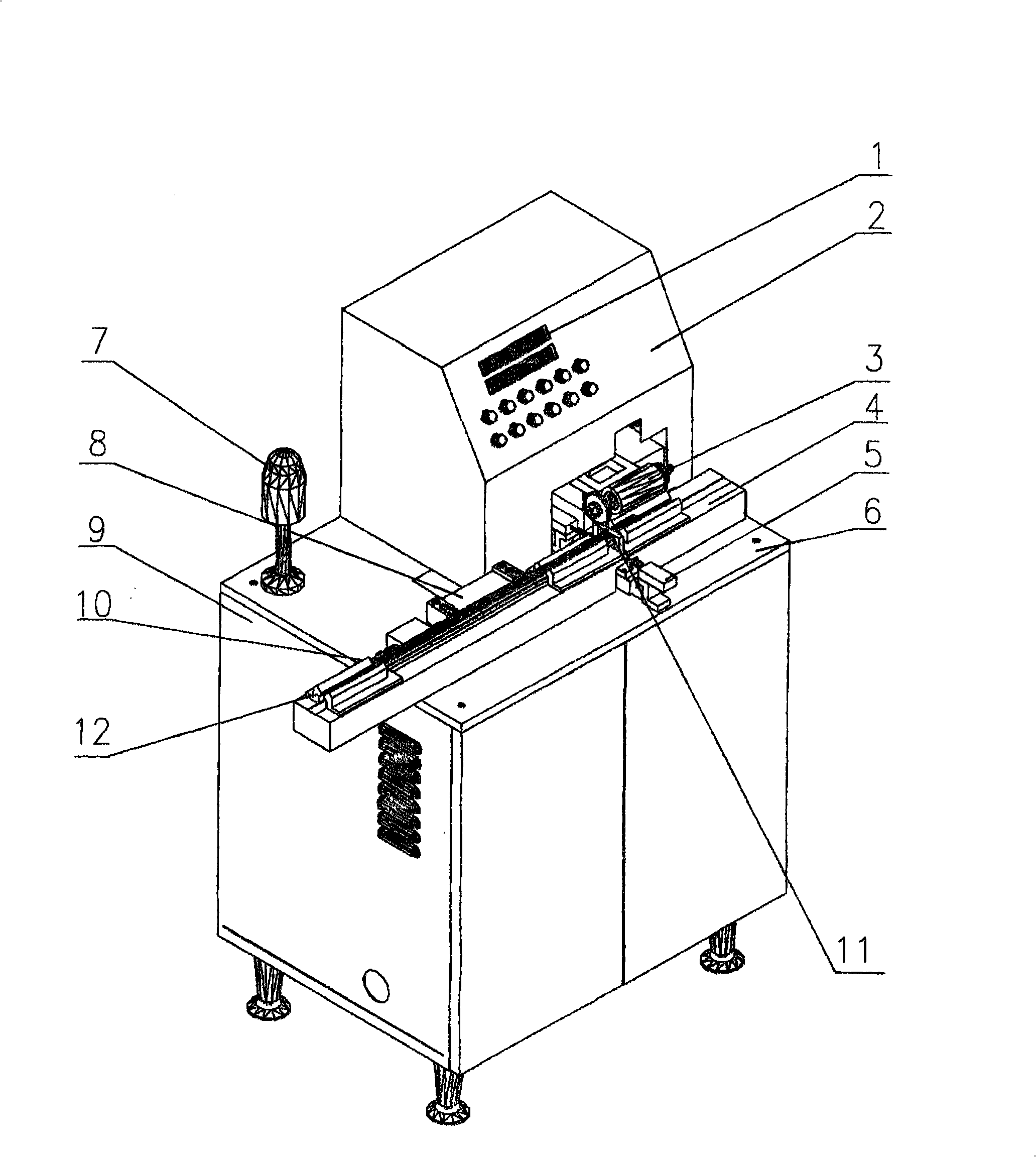

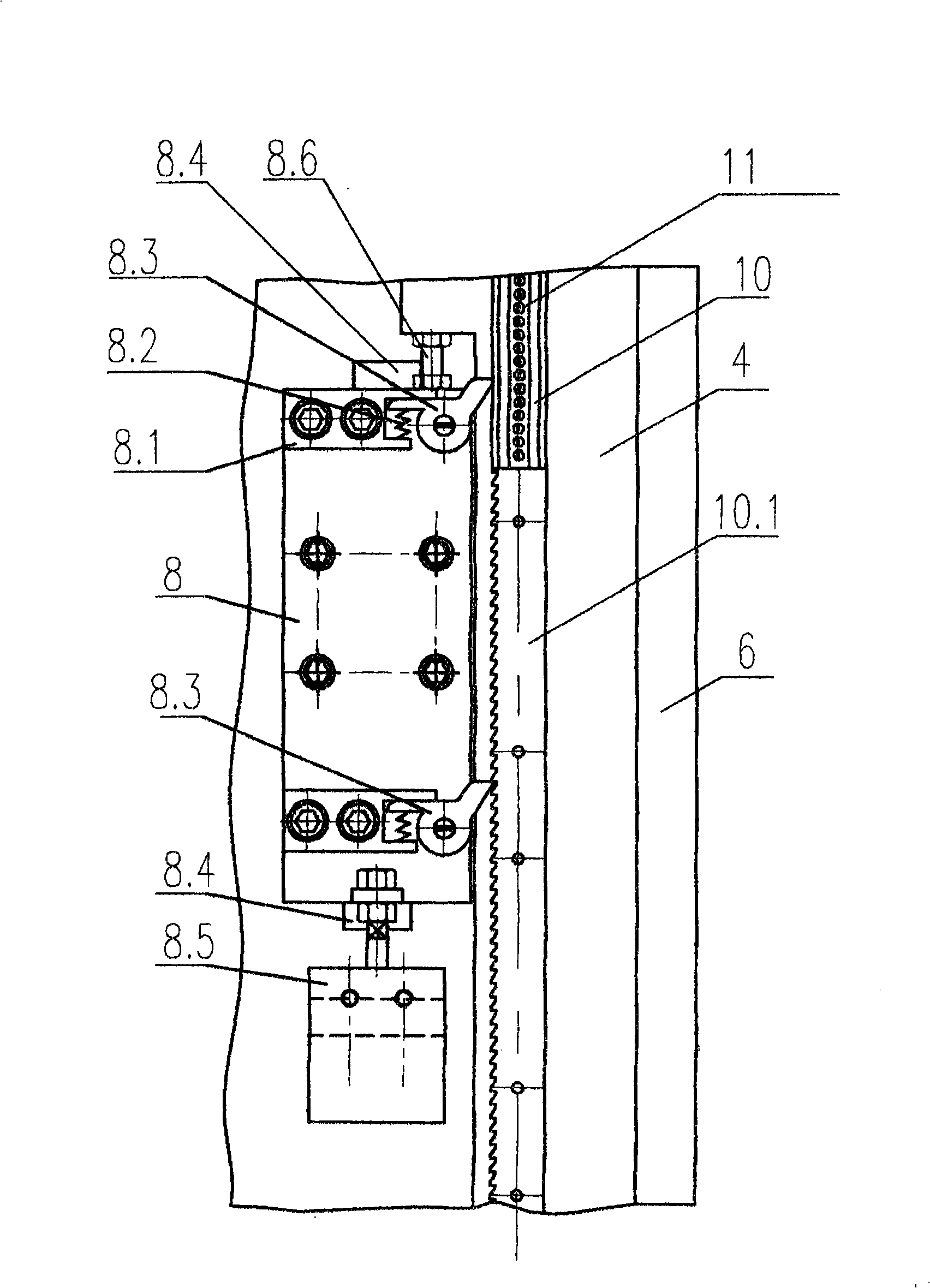

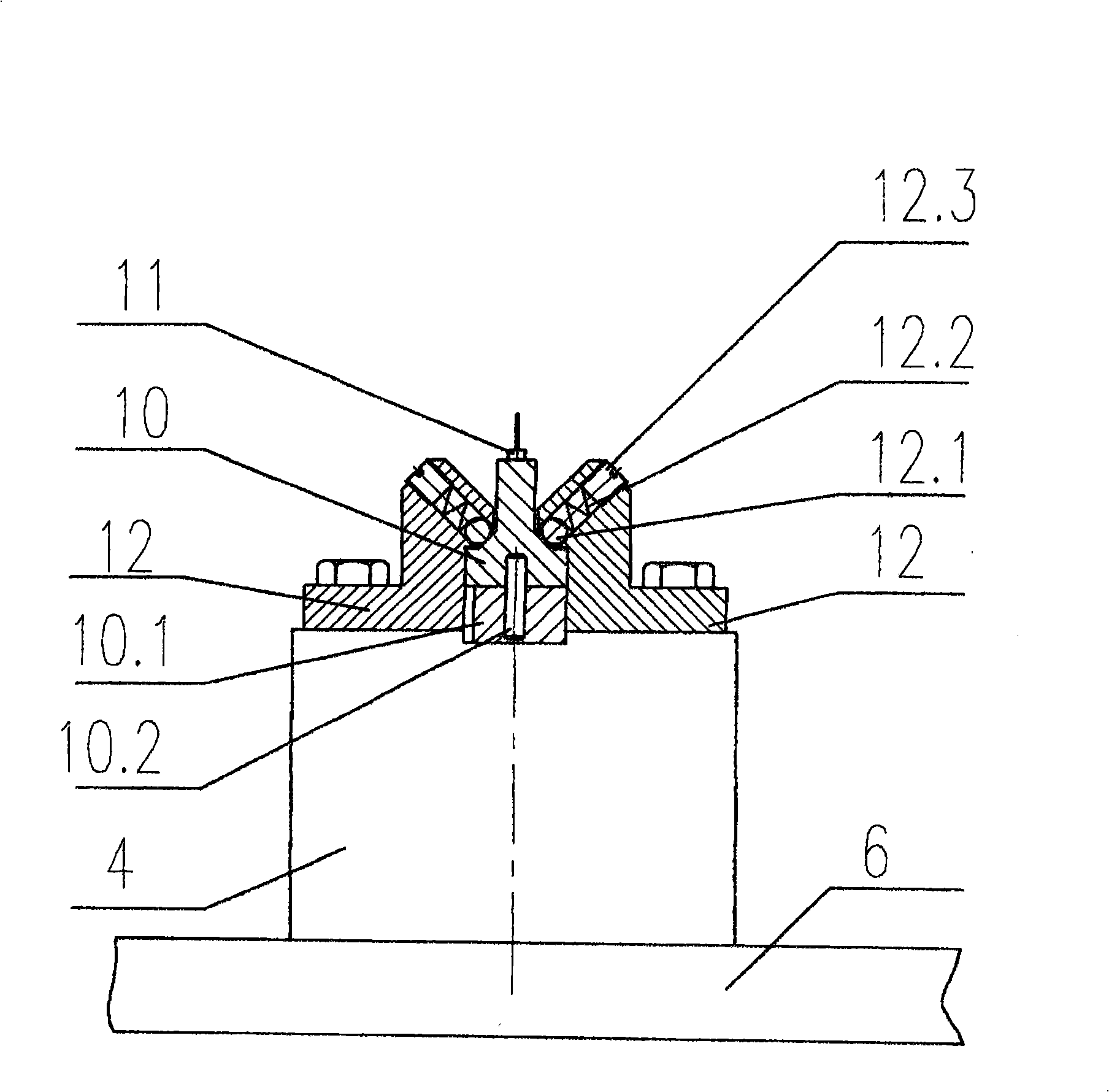

[0018] Such as figure 1 , 2 , 3, 4, 5, and 6, which will be further explained below in conjunction with the accompanying drawings:

[0019] The columnar crystal automatic frequency modulation machine of the present invention mainly includes figure 1 The appearance structure of the machine in, figure 2 The automatic feeding assembly in image 3 The automatic feeding buffer system in Figure 4 The automatic clamping and frequency measurement assembly in Figure 5 automatic grinding FM system in and Image 6 In the intelligent control platform, its working characteristics are as follows: 2 movable ratchets 8.3 are installed on the ratchet fixed plate 8, under the action of the feeding cylinder 8.5, the rack is automatically pushed forward along the guide rail 8.4 on the installation base plate 6 10.1 is connected with the crystal positioning seat 10 equipped with the columnar crystal 11 of the workpiece to be processed. Between the crystal positioning seat 10 and the rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com