Test system for feeder automation system

A feeder automation and testing system technology, applied in the field of feeder automation, can solve problems such as heavy burdens and difficulties, and achieve the effect of reducing burdens and solving signal isolation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

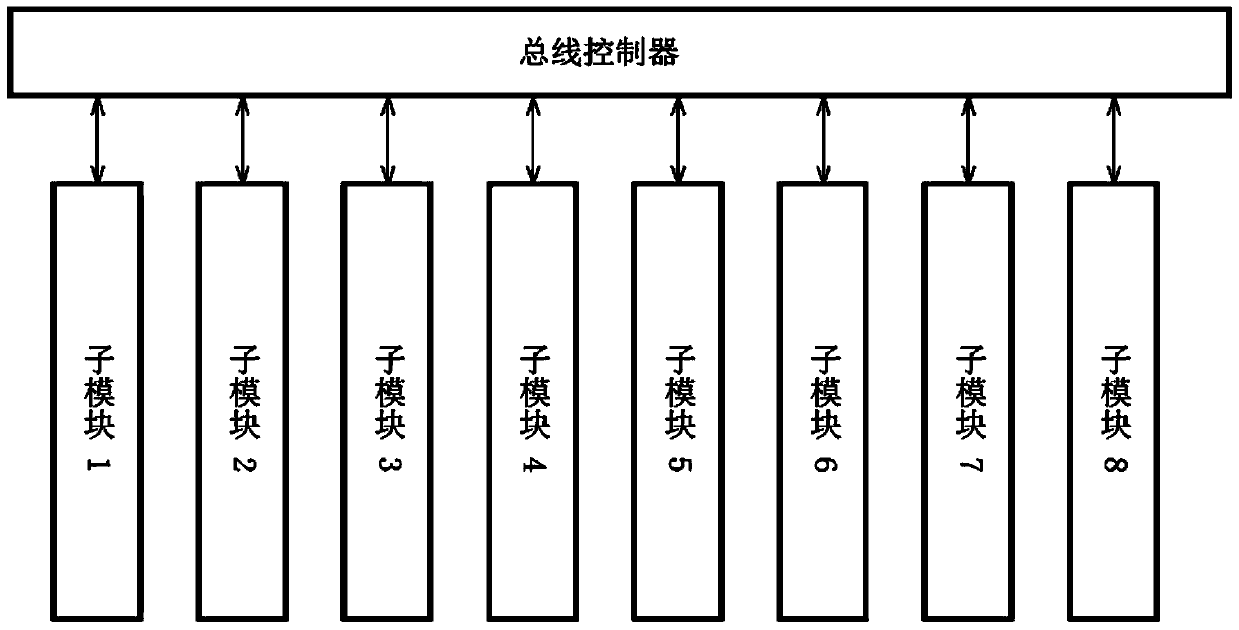

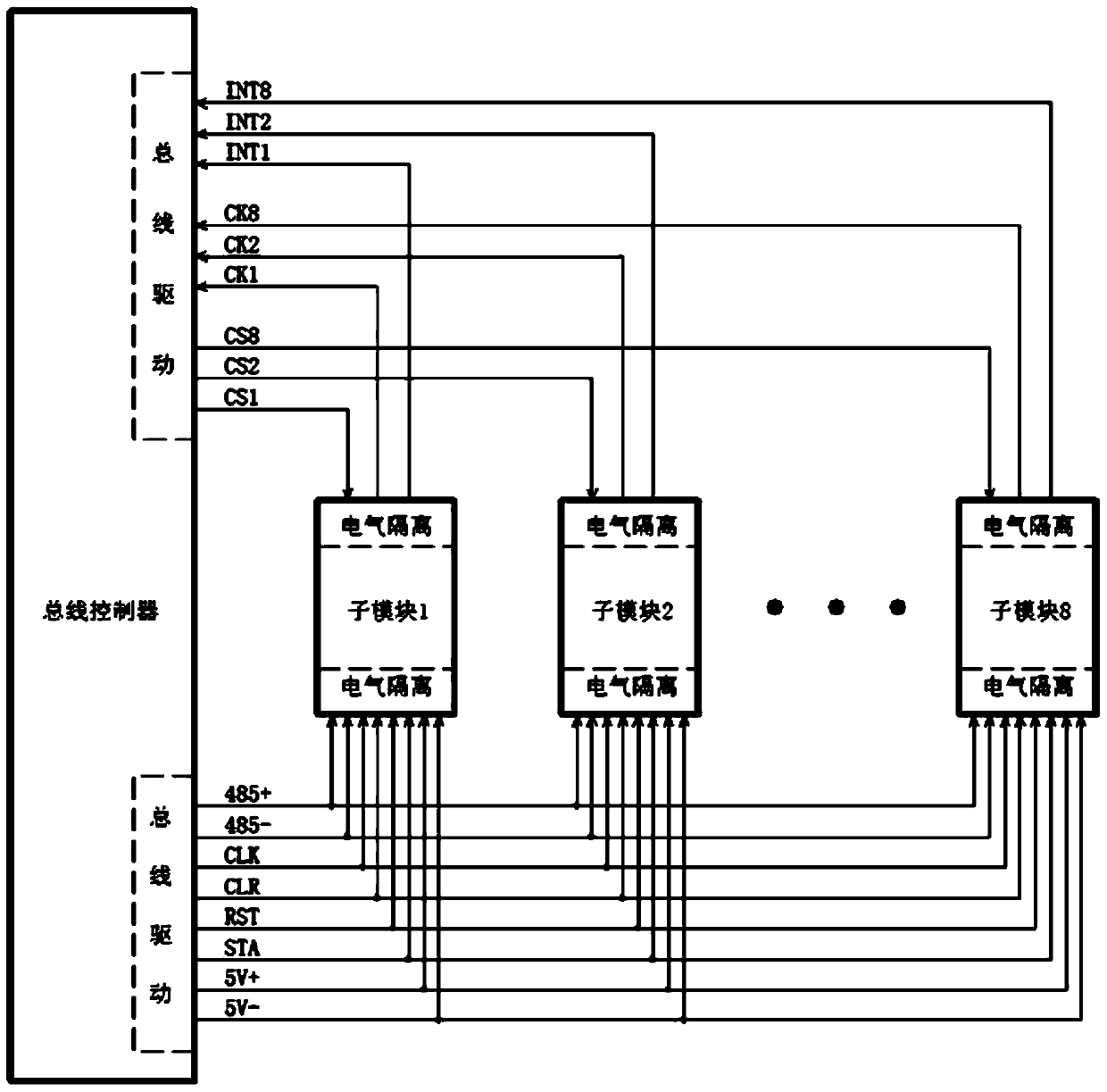

[0029] The following will combine figure 1 and figure 2 The test system of the feeder automation system provided by the present invention is described in detail, which is an optional embodiment of the present invention, and it can be considered that those skilled in the art can modify it within the scope of not changing the spirit and content of the present invention and polish.

[0030] This embodiment provides a test system for a feeder automation system, including several sub-modules and a bus controller; in this embodiment, the number of the sub-modules is eight; each of the sub-modules is configured with a sub-module MCU, The bus controller can be configured with a main MCU;

[0031] The communication signal transmission is realized between the bus controller and each of the sub-modules through the first type of connection line;

[0032] The transmission of control signals between the bus controller and each of the sub-modules is realized through the second type of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com