Polarizing plate and manufacturing method thereof and display screen

A polarizer, polarizer technology, applied in polarizing elements, optics, optical elements, etc., can solve the problems of uneven brightness, random defects, and increased products of displays, so as to reduce the probability of defective products, reduce static electricity, and facilitate The effect of process production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

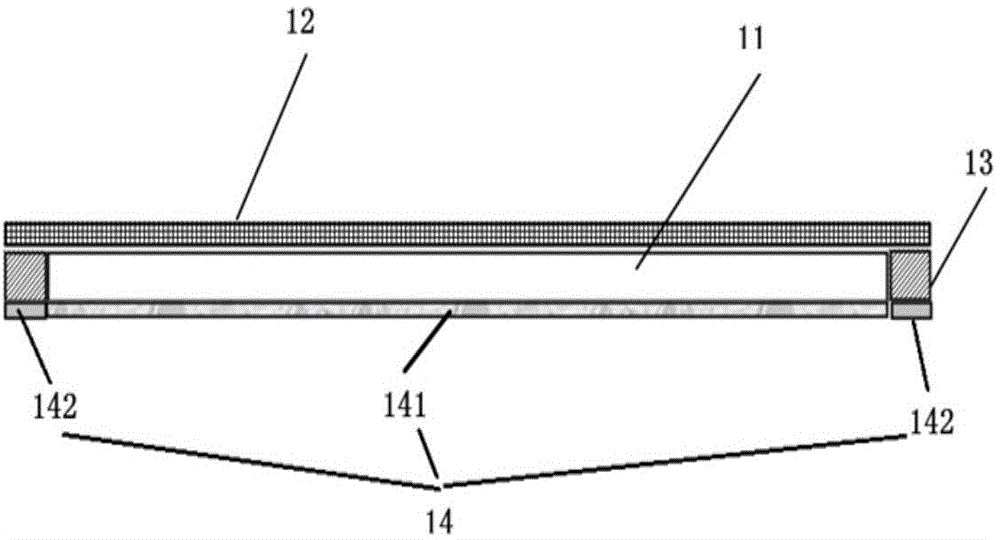

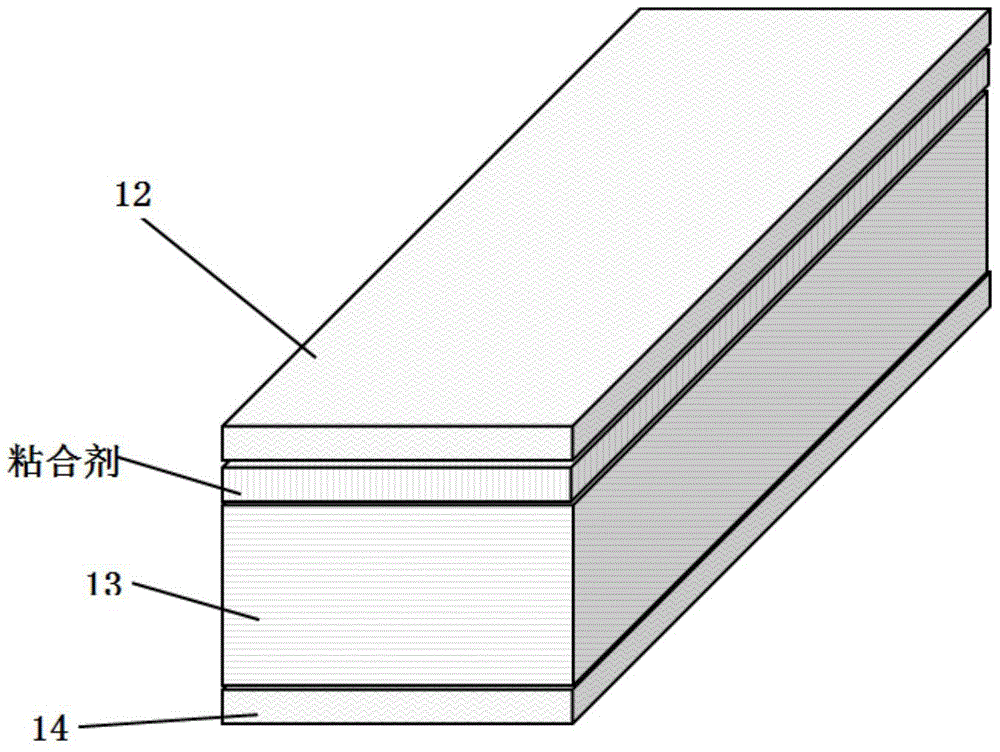

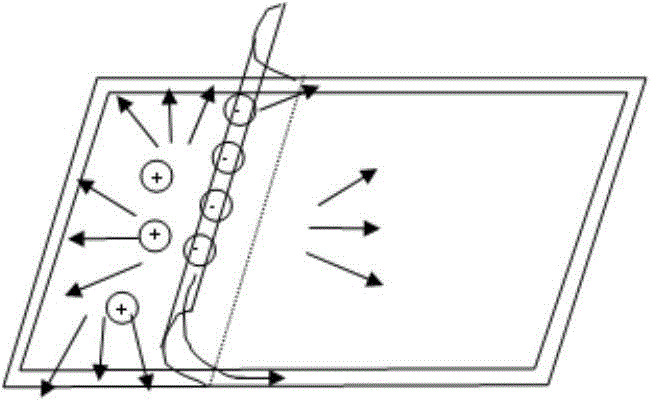

[0039] The polarizer provided by the embodiment of the present invention includes a polarizer main layer 11, a protective film layer 12, a conductive layer 13 and a release film 14, wherein: the first outer surface of the polarizer main layer 11 is coated with a protective film layer 12 ; The second outer surface of the polarizer main layer 11 is coated with a release film 14 ; the periphery of the polarizer main layer 11 is coated with a conductive layer 13 . Such as Figure 1a As shown, it is a schematic diagram of the basic structure of the polarizer provided by the embodiment of the present invention. From bottom to top, it is a release film 14, a polarizer main layer 11, a conductive layer 13 located on the periphery of the polarizer main layer 11, and a protective film layer 12. . Wherein, the release film 14 may include two parts, one part is the release film 141 in contact with the main body layer 11 of the polarizer, and the other part is the release film 142 in conta...

Embodiment 2

[0044] The polarizer provided by the embodiment of the present invention increases the conductivity of charges and increases the release path of charges through structural design. Preferably, during specific implementation, the protective film layer 12 is pasted on the main body layer 11 of the polarizer through a pressure-sensitive adhesive layer. In order to further improve the conductivity of charges, the pressure-sensitive adhesive layer of the protective film layer 12 can be a specially treated adhesive layer with good conductive diffusivity, and the adhesive layer whose conductive diffusivity parameter is greater than a preset threshold can be selected. For example, the pressure-sensitive adhesive layer can be, but not limited to, conductive polymer material, electrical network, material doped with carbon black or doped with conductive particles.

Embodiment 3

[0046] In order to further improve the conductivity of charges, a metal film is vapor-deposited on the surface of the polarizer provided in the embodiment of the present invention in contact with the protective film layer 12 . During specific implementation, any general metal film is acceptable. The metal film not only has good electrical conductivity, but also can generate polarized light through the grid structure. The grid structure of the metal film refers to a strip-shaped light leakage structure like a grating. Usually, the slits of the grating are on the order of mm (millimeters). During specific implementation, considering the difficulty of processing, preferably, the metal film may be a copper film or an aluminum film. More preferably, the polarization direction generated by the metal film grid is consistent with the polarization direction of the main layer 11 of the polarizer.

[0047] In practice, the thickness of the conductive layer 13 is the same or close to tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com