DOE (design of experiments) method for controlling surface holes when aluminum alloy precision die-casting fittings are machined

A surface hole, aluminum alloy technology, applied in the direction of comprehensive factory control, digital control, electrical program control, etc., can solve the problem of high scrap rate, achieve the effect of improving pass rate, reducing cost, and reducing hole leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

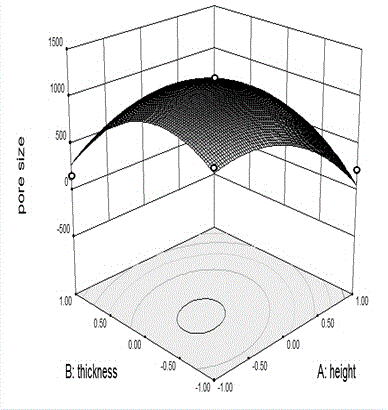

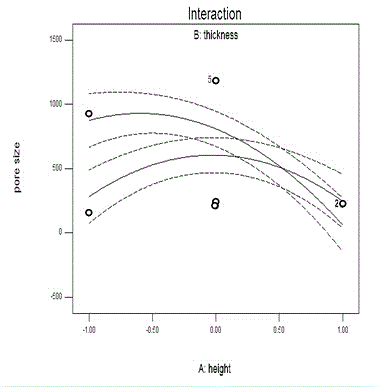

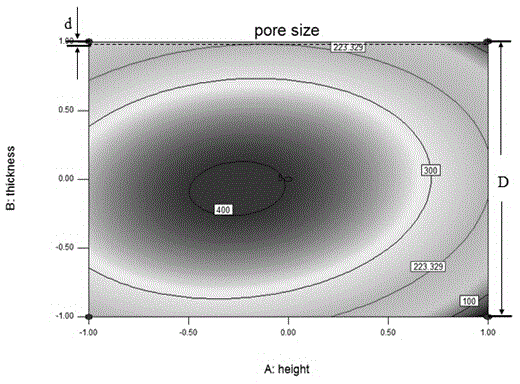

Method used

Image

Examples

Embodiment 1

[0055] In the process of precision die-casting for the production of auto parts for the object of ADC12 aluminum alloy air-conditioning compressor, due to the limitation of production process parameters, there are too many casting holes on the surface of some parts after machining, and the product quality is reduced. The return of goods due to the buyer's request not only increases the scrap rate and production cost, but also affects the reputation of the supplier. After adopting the process of the present invention, since the distribution of holes inside most castings can be grasped more accurately, the phenomenon of parts being scrapped due to the randomness caused by the lack of machining allowance standards in the previous machining process has been improved, and the previous relatively low cost has been reduced. High scrap rate of parts reduces production cost while improving product quality.

[0056] Table 1 Coordinates of selection points determined by alpha value in De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com