Control Method of Dual Motor Servo System Based on Segmented Neural Network Friction Model

A dual-motor servo and friction model technology, which is applied to motor generator control, electronic commutation motor control, control systems, etc., can solve problems that have not been mentioned in any invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

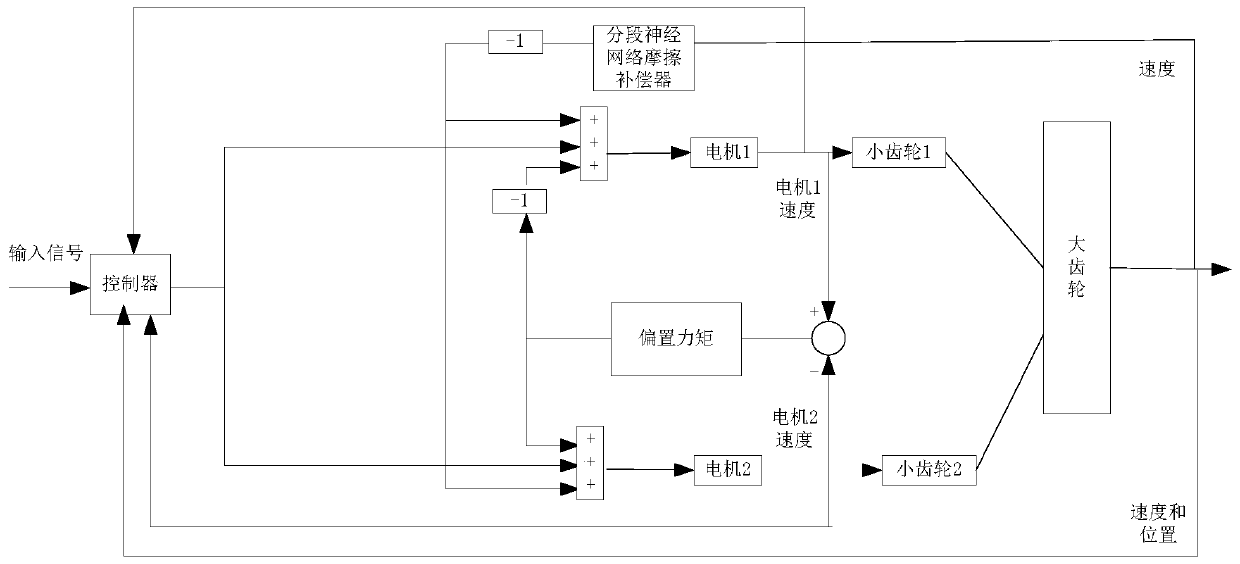

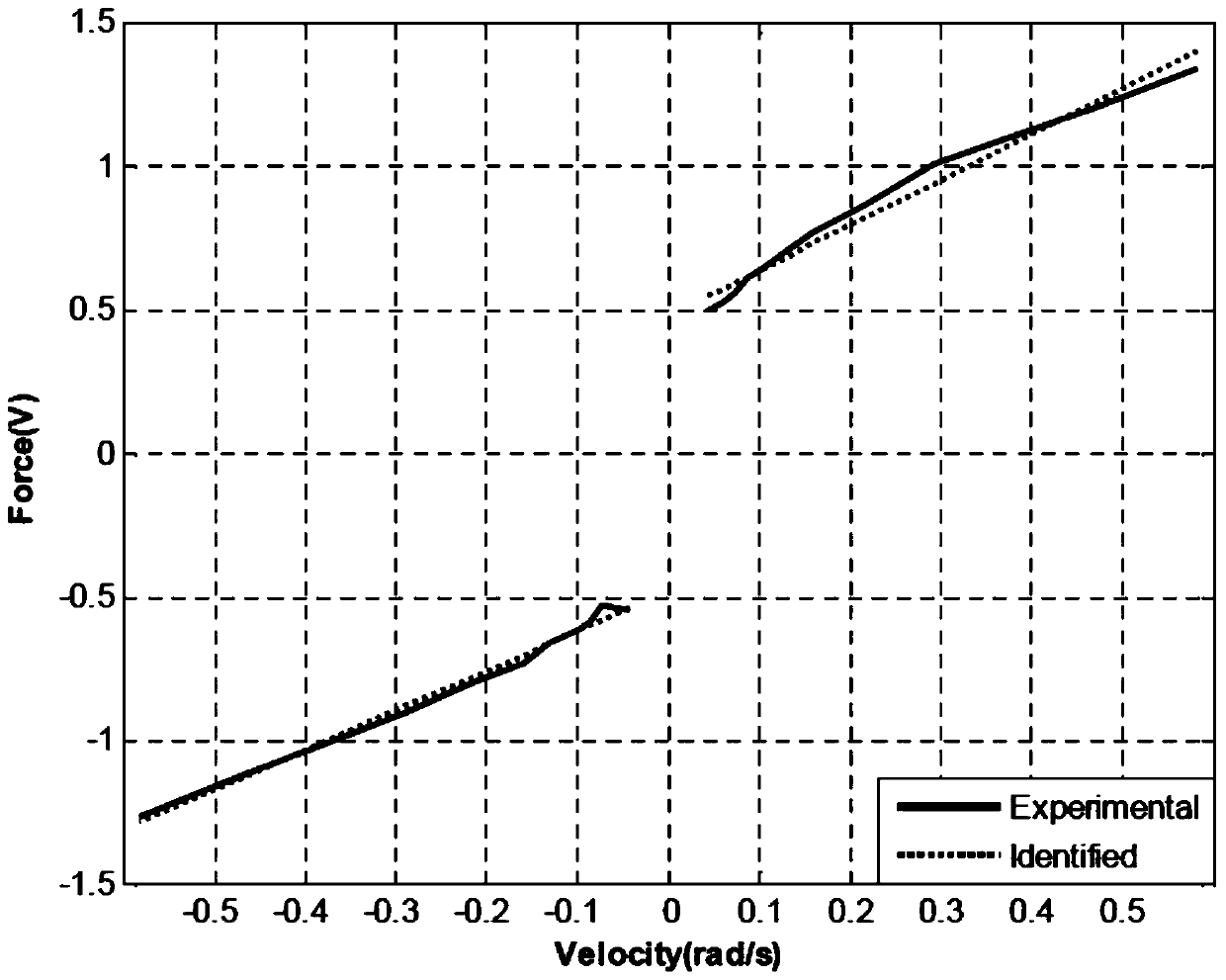

[0090] A method for controlling a motor servo system based on a segmented neural network friction model, comprising the following steps:

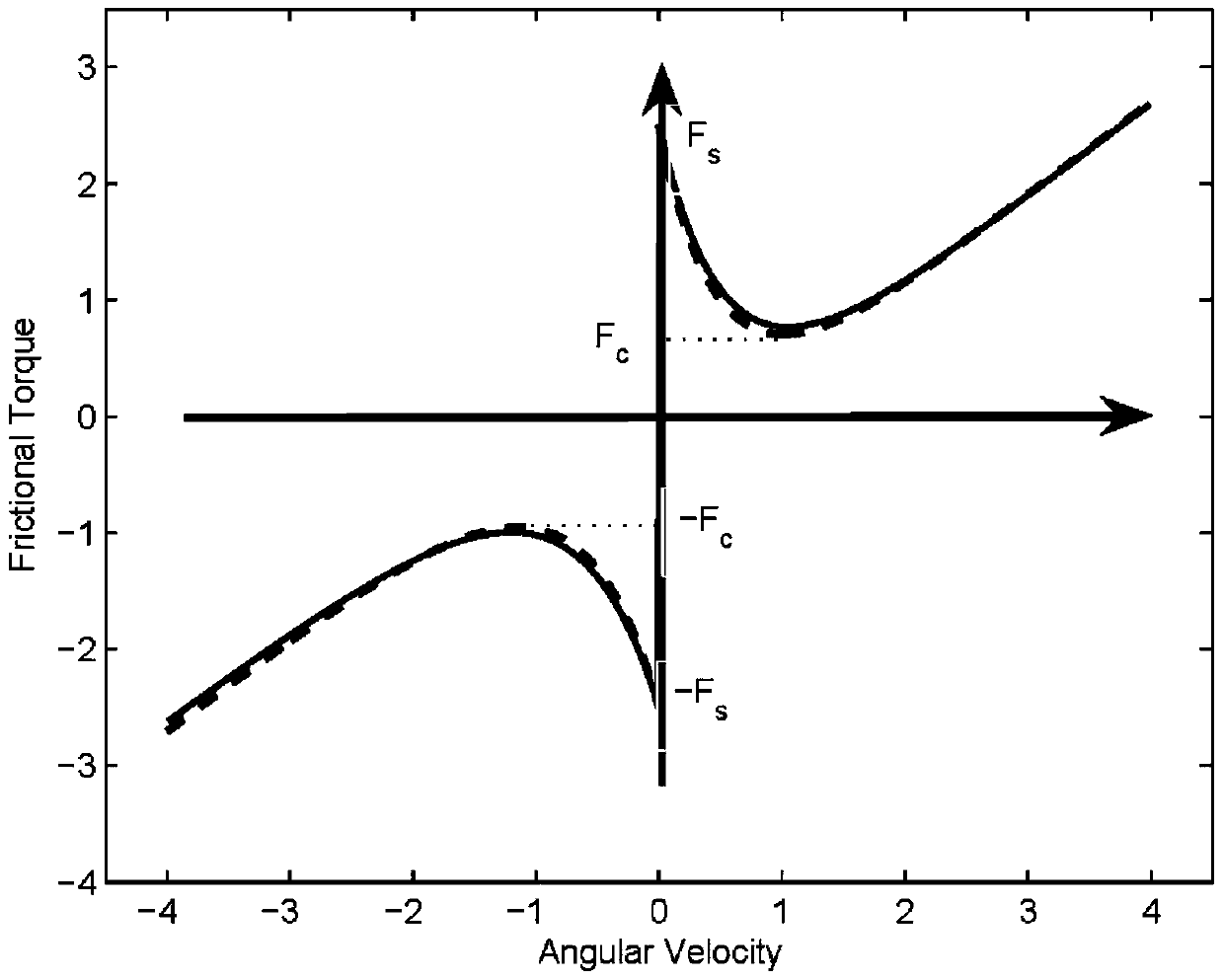

[0091] Step 1. Analyze the friction-containing dual-motor drive servo system, and establish a mathematical model of the friction-containing dual-motor drive servo system according to the mechanism modeling method, according to the structure and physical laws of the motor, as follows:

[0092]

[0093] in,

[0094]

[0095]

[0096] In formula (24), formula (25) and formula (26), θ i (i=1,2) and θ m represent the rotation angles of the driving end and the load end, respectively; and Respectively represent the rotational speed of the drive end and the load end; and Respectively represent the acceleration of the driving end and the load end; J represents the moment of inertia o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com