Cage for inclined ball bearing

A technology for cages and rolling bearings, applied to ball bearings, bearings, bearing components, etc., can solve the problems of increased waste, logistics problems, etc., and achieve the effect of high load capacity and small axial width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

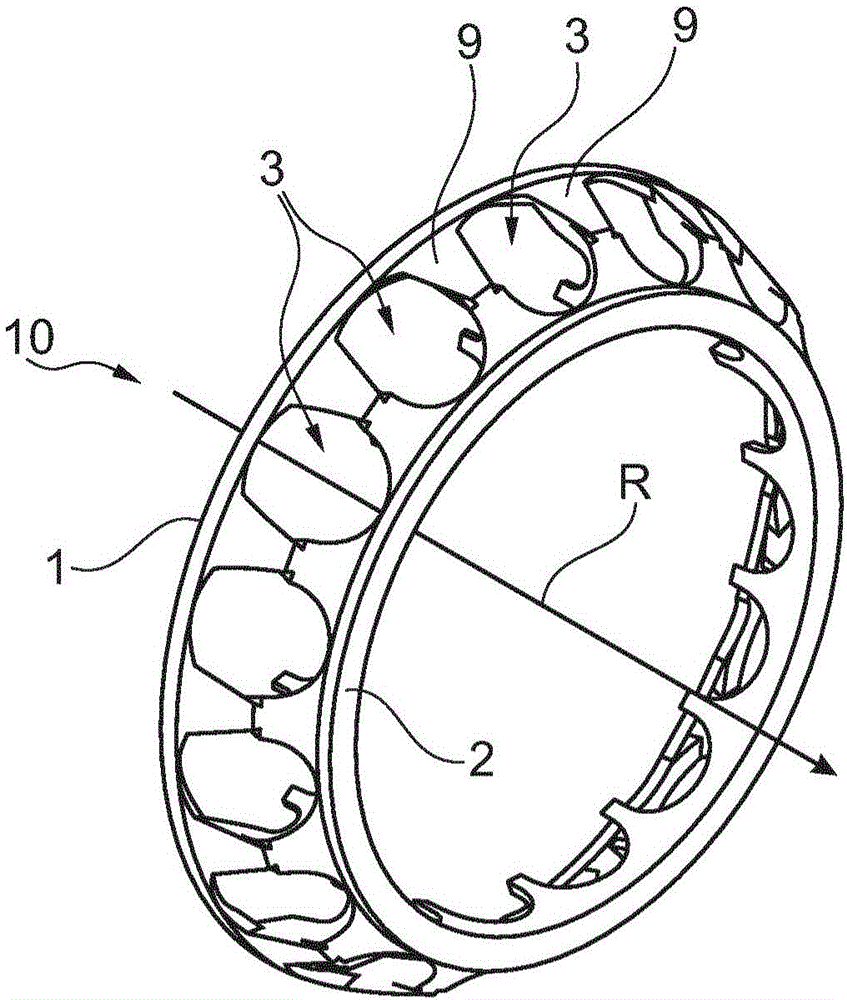

[0025] figure 1 A radial thrust ball bearing cage 10 with an axis of rotation R is shown. The ball pockets 3 are separated by webs 9 , wherein the webs 9 also connect the rings 1 , 2 to each other and provide sufficient stability.

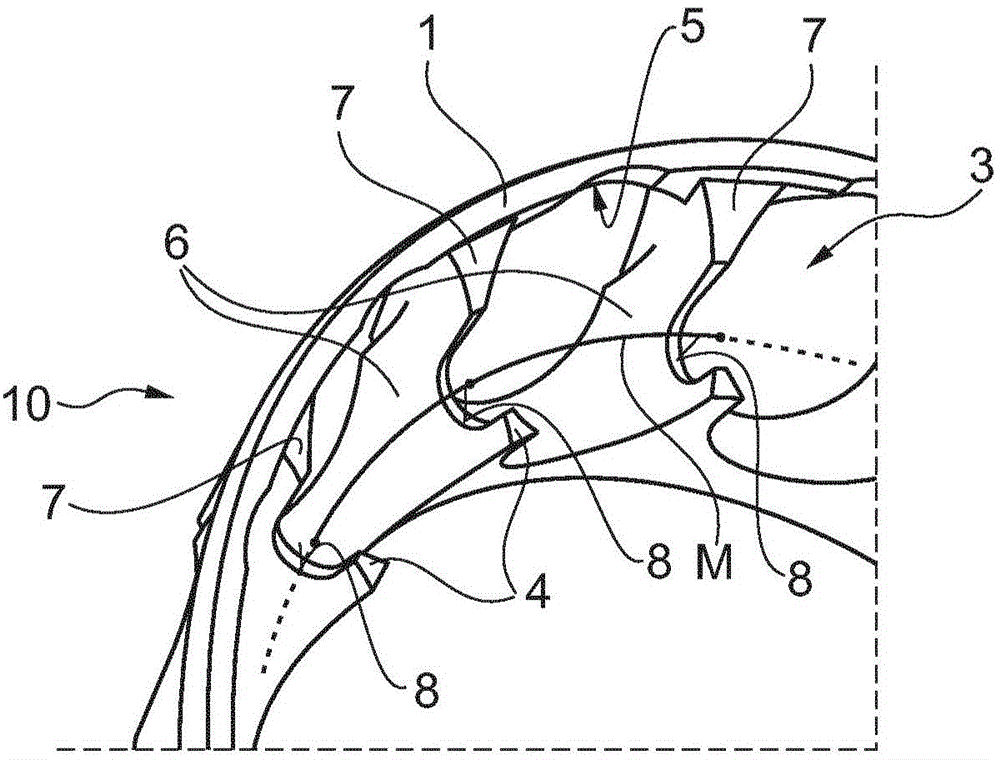

[0026] figure 2 A section of the radial thrust ball bearing cage 10 is shown, wherein the region of the fork 8 around the three webs 9 can be seen more precisely. The free end 4 together with the first end 7 of the web 9 forms the desired fork 8 . The fork 8 is open in an axial direction directed towards the first ring 1 . This characteristic leads to the logistical advantage that cages of the same size can be stacked in a staggered manner, wherein the second ring 2 of the cage is inserted into the fork 8 of the adjacent cage.

[0027] Furthermore, the rings are overall designed in such a way that they do not catch on each other and can therefore be easily detached. This characteristic is mainly based on the construction of the first ring.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com