Chain connecting element with security connector piece

A technology of chain connection and components, applied in the direction of chain buckles, shackles, etc., can solve problems such as increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

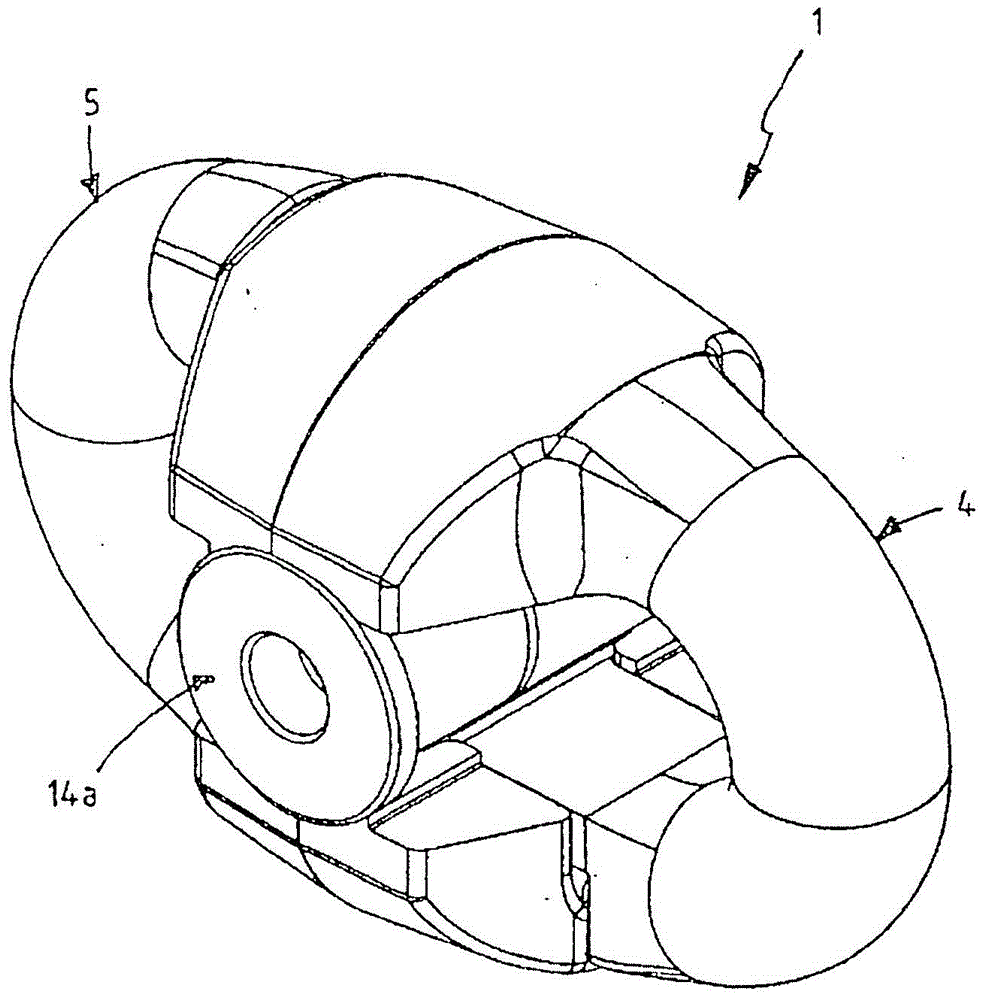

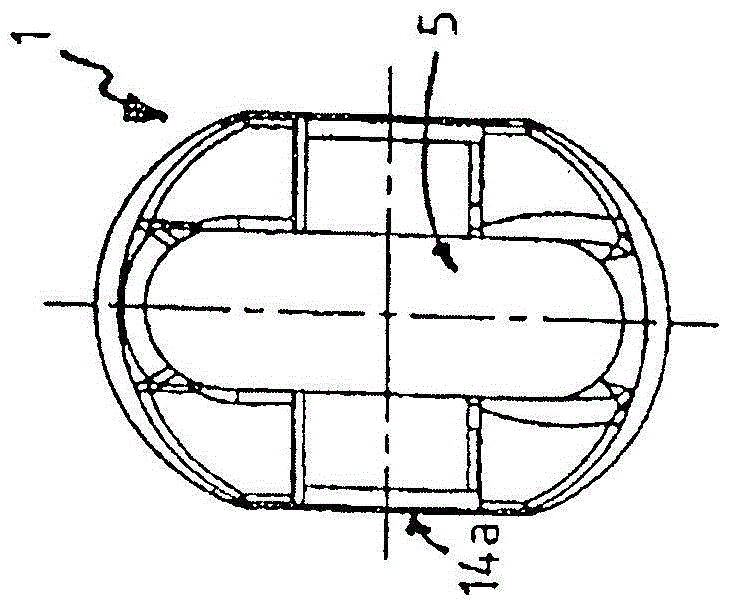

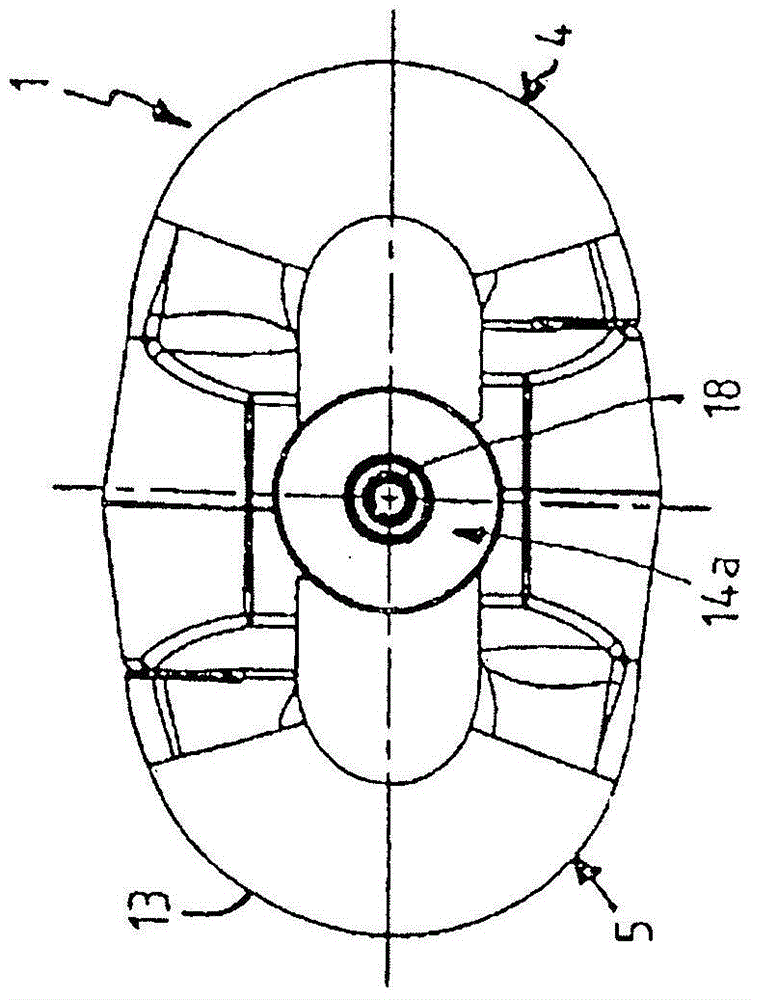

[0029] In the various figures, the same or similar components are provided with the same reference numerals, even if a repeated description is omitted for reasons of simplification.

[0030] FIGS. 1 a to 3 f each chain link element 1 - 3 has two identical chain link brackets 4 , 5 coupled via their side legs, which are of identical design in all the figures. A side leg 6 of each chain link bracket 4 , 5 now has a neck section 7 and a tenon 8 thickened relative to the neck section. A neck recess 10 and a tenon recess 11 are correspondingly provided on the other side leg 9 of the link bow 4 , 5 . According to the invention, on each tenon 8 and on each tenon recess 11 there is provided a side surface 12 conically formed with respect to the longitudinal mid-plane MLD of the tenon 8 (see also Figure 4 and Figure 5). Furthermore, the length L of the leg 6 is dimensioned such that the transverse mid-plane MQE of the chain connection elements 1 - 3 intersects the tenon 8 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com