Gearbox device, in particular for actuators in motor vehicles

A technology of transmission mechanism and adjustment device, which is applied in the direction of power control mechanism, wing control mechanism, hoisting device, etc., which can solve the problems of inability to suppress axial impact, and achieve the effect of simple connection and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

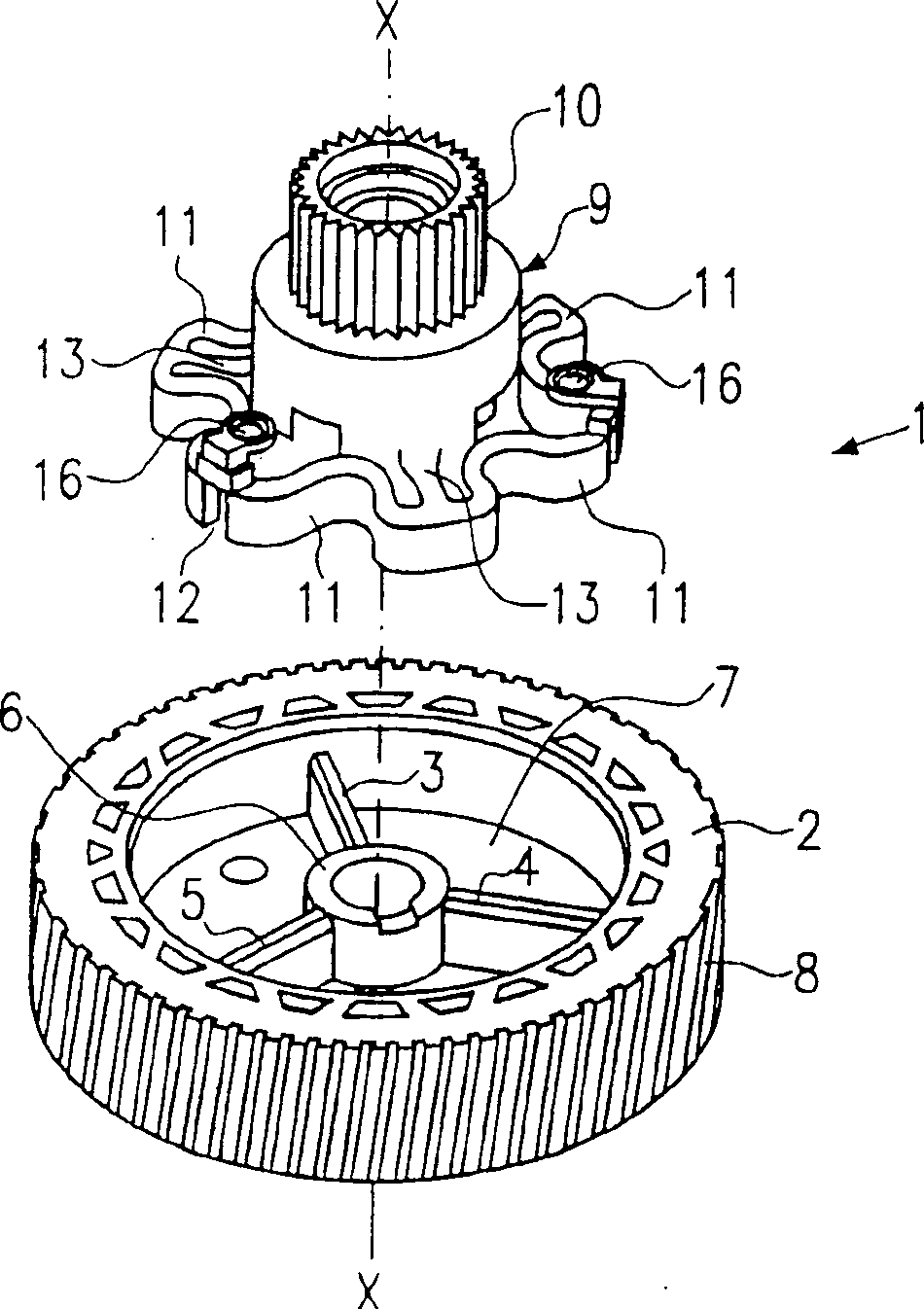

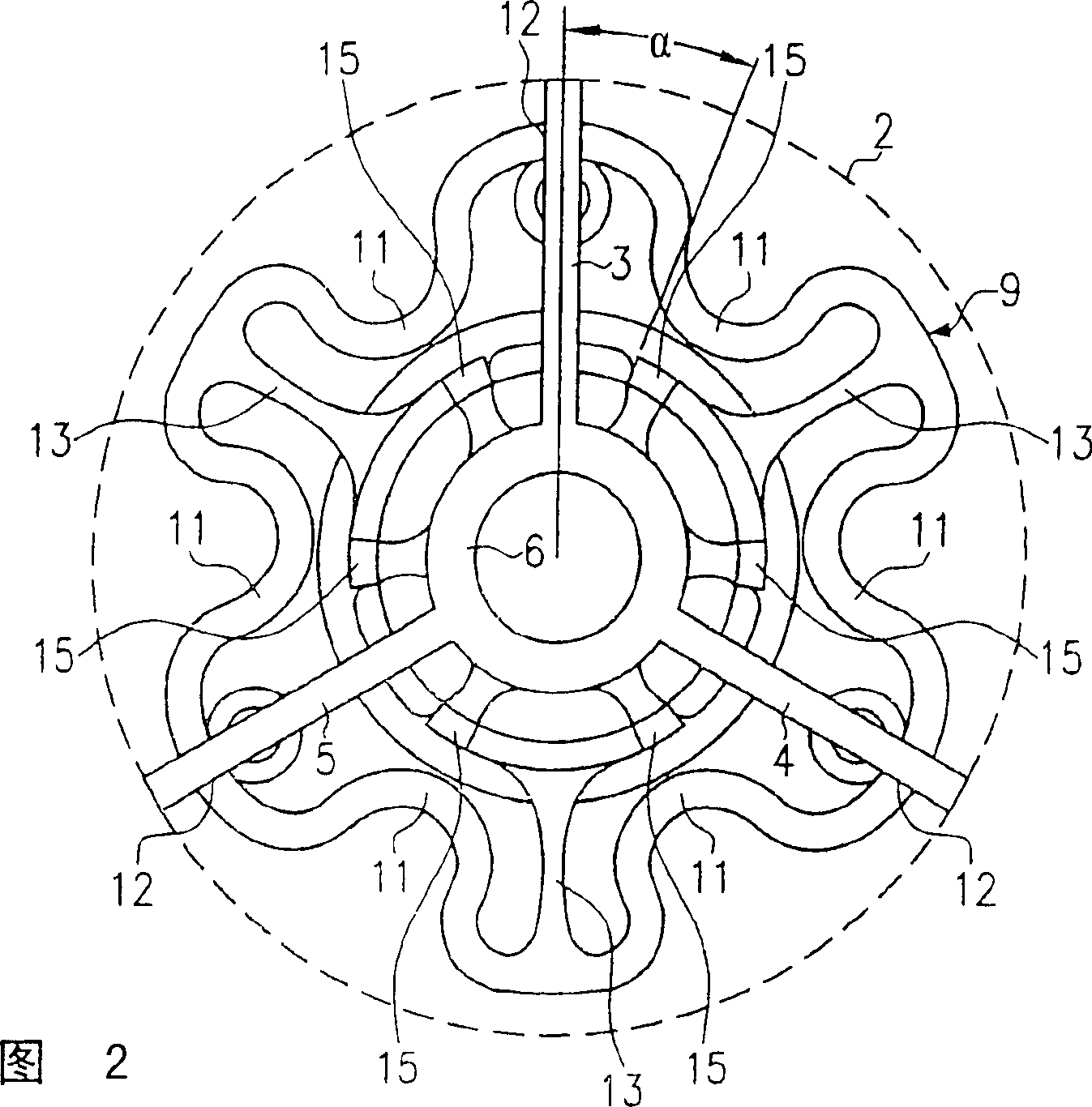

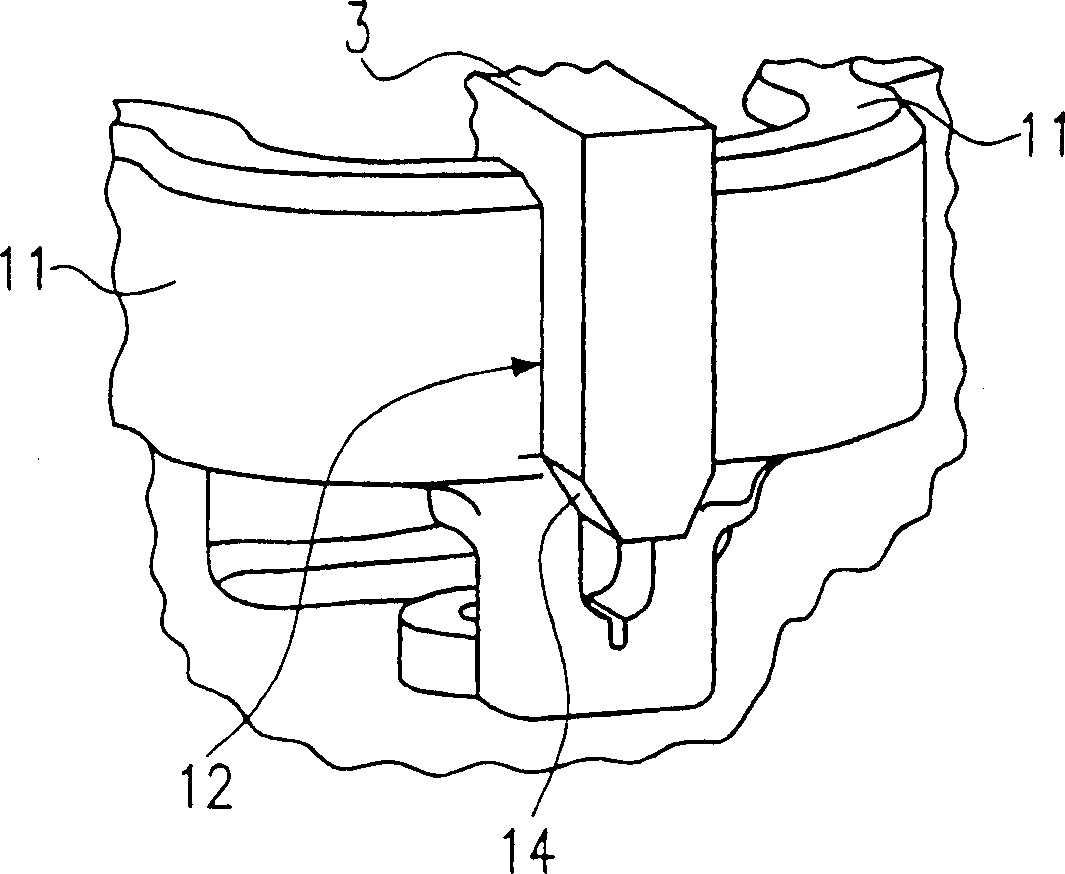

[0019] Below, refer to Figures 1 to 3 A transmission mechanism according to a first embodiment of the present invention will be described.

[0020] Such as figure 1 It is shown that the transmission mechanism 1 comprises a first transmission member in the form of a spur gear 2 and a second transmission member in the form of a synchronizer 9 . The spur gear 2 is designed essentially as a ring gear and has ribs 3 , 4 , 5 which are connected to a central bore 6 for supporting the spur gear 2 on a bearing pin not shown superior. On the outer circumference of the spur gear 2 is formed a gear tooth 8 in the shape of a helical tooth, which is driven by an electric motor via a worm. Furthermore, the spur gear 2 has a base 7 at its end in the axial direction.

[0021] Synchronizing element 9 includes a pinion 10 and is likewise supported on the bearing pin, not shown. Furthermore, an integral damping element is formed on the synchronization element 9 in the form of a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com