Combined type material package and material feeding method thereof

A technology of combining materials and combining material boxes, which is used in cooking utensils, household appliances, applications, etc., can solve the problems of raw material boxes that cannot be automatically or semi-automatically reset, are polluted, and are large in size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

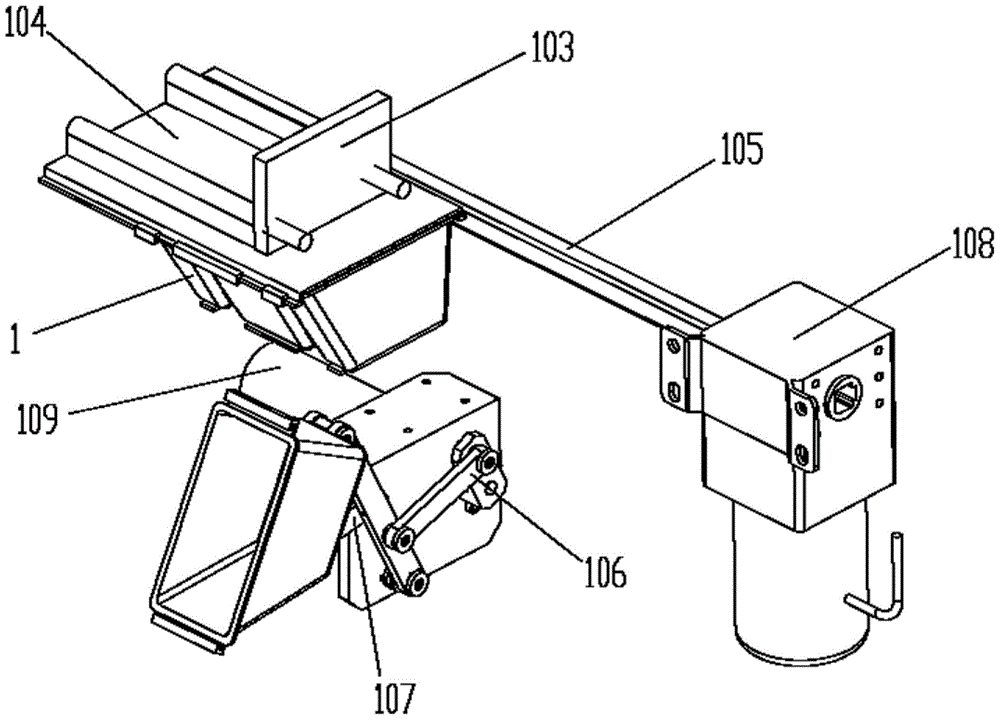

[0081] Please refer to figure 1 , the combined material box includes four material packaging units (hereinafter referred to as sub-material boxes). What the sub-material box 1 adopts is the free combination type, and its sealing device and the connection device of each sub-material box 1 are the same sealing plate 104, and the sealing plate 104 has a fixing device. The longitudinal feeding of the sub magazine is driven by the motor 108 through the rack 105 . When feeding, the sealing plate 104 is fixed on the support 103, and the longitudinal drive of the motor 108 drives the sub-material box 1 to slide on the sealing plate 104, and the sliding distance is the width of the sub-material box 1. When the sub-material box 1 slides, its front end slides into the grasping mechanism 107, and the rear end just comes off from the sealing plate 104. After falling off, the overturning feeding of the sub-material box 1 is driven by the motor 109 through the crank-link rocker mechanism 1...

Embodiment 2

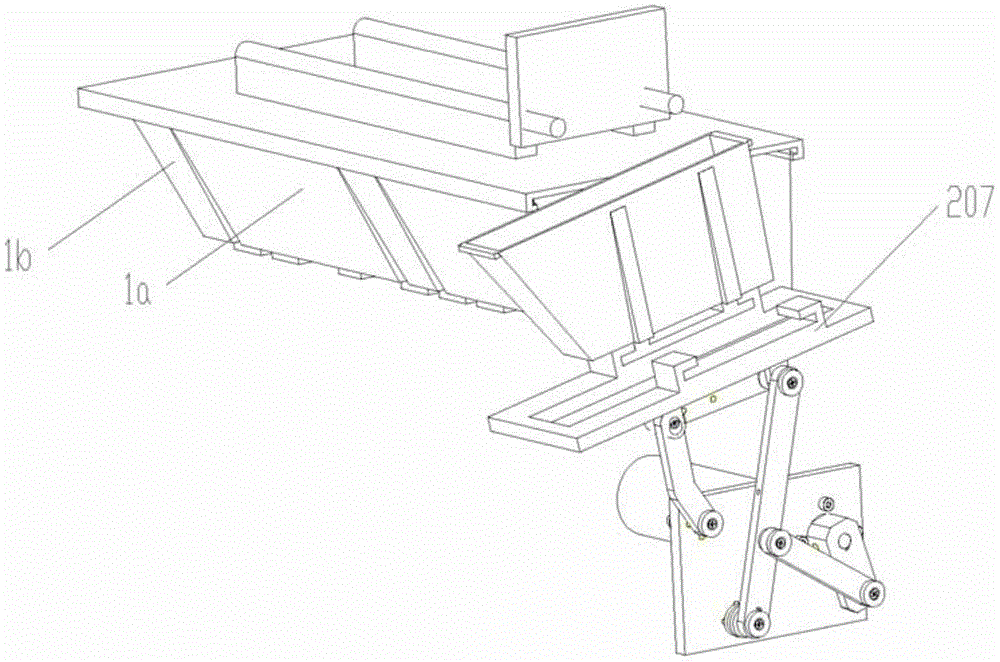

[0083] Please refer to figure 2 , The improvement of this embodiment relative to Embodiment 1 lies in the structure of the box cover and the grabbing mechanism. There is a groove at the front of the material box in Example 1, and the material may accumulate in the groove when feeding, making it difficult to clean; since the width of the main material box 1a and the auxiliary material box 1b are very different, if a single claw is used to grab , for the main material box 1a, only one side of the bottom surface of the main material box 1a can be grasped, so that the main material box 1a itself will have a relatively large torque. In order to solve this problem, a grabbing mechanism 207 with two claws is adopted: when When grabbing the auxiliary material box, use the claw on the left in the figure to grab it. When the auxiliary material box is finished feeding and resets, under the action of the rear thrust, the auxiliary material box 1b falls from the gap in the middle of the g...

Embodiment 3

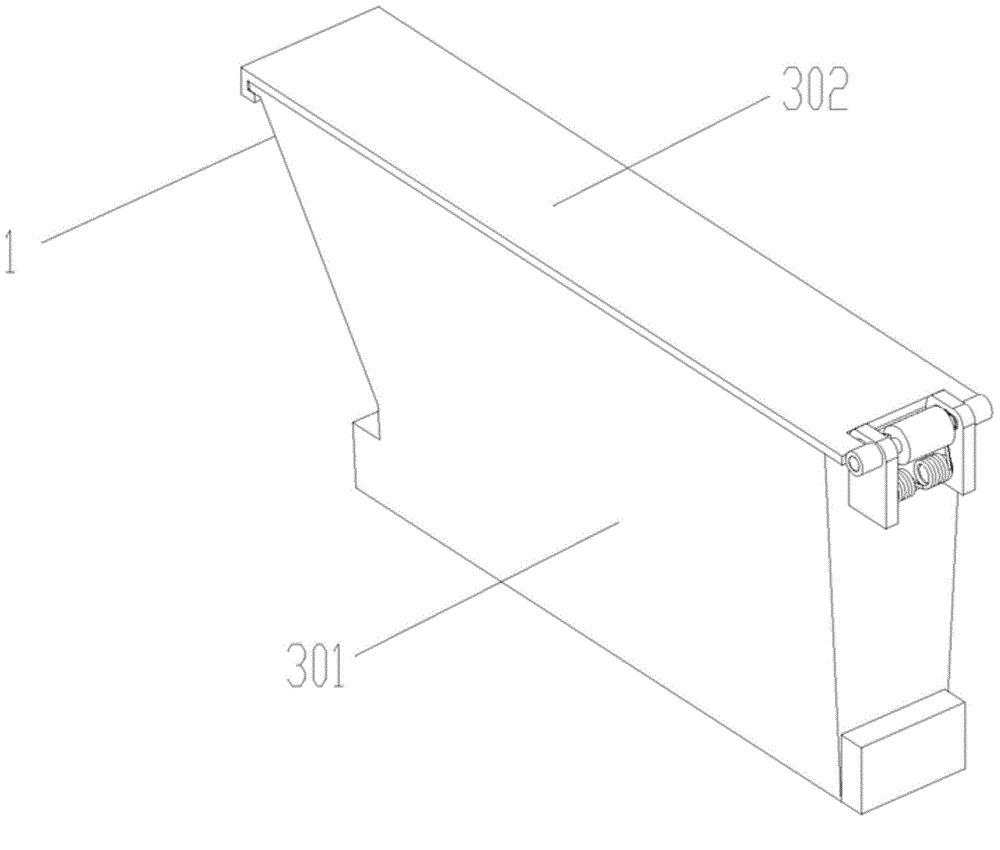

[0085] Please refer to Figure 3 to Figure 7 , each sub-box 1 is installed in a frame 32 through a clamping strip 31, thereby forming an integral combined magazine 2.

[0086] The sub-cartridge 1 includes a box body 301 and a box cover 302 , and the box cover 302 is connected to the box body 301 through a rotating shaft 303 . In the sealed state, the buckle 308 is buckled on the box body 301 by the force of the torsion spring 304. When opening the cover, the rotating shaft 303 is moved forward along the chute 306 by the force exerted on the roller 305, thereby opening the box cover 302 .

[0087]The cover opening mechanism 300 of the sub-material box 1 includes a crank slider mechanism 3001, a rocker 3002, a moving shaft 3003 and a fixed shaft 3004. When the sub-material box 1 is turned down, the crank slider mechanism 3001 is driven to move, that is, the moving shaft 3003 Rotate around the fixed shaft 3004, thereby driving the rocker 3002 to rotate and push the roller 305 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com