Emulsified liquid circulating apparatus

A technology of emulsion circulation and circulation pool, which is applied in the field of lubrication and cooling equipment of steel processing production line, can solve the problems of blocked emulsion circulation channel, large emulsion flow resistance, complex structure, etc., and achieves reduction of evaporation loss, low cost, and increased The effect of equipment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

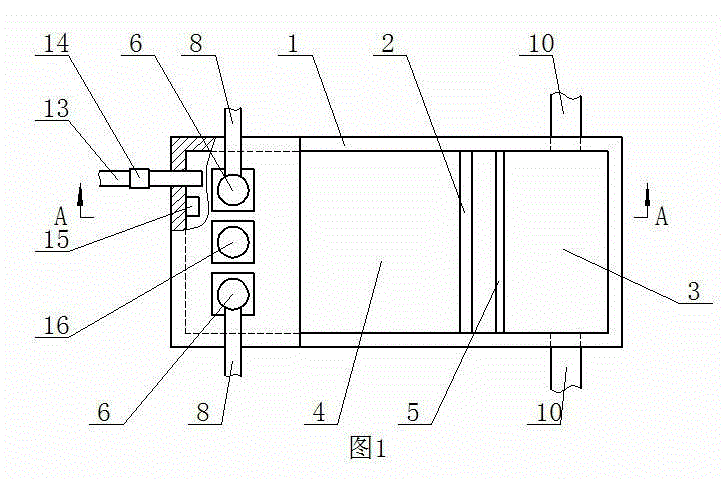

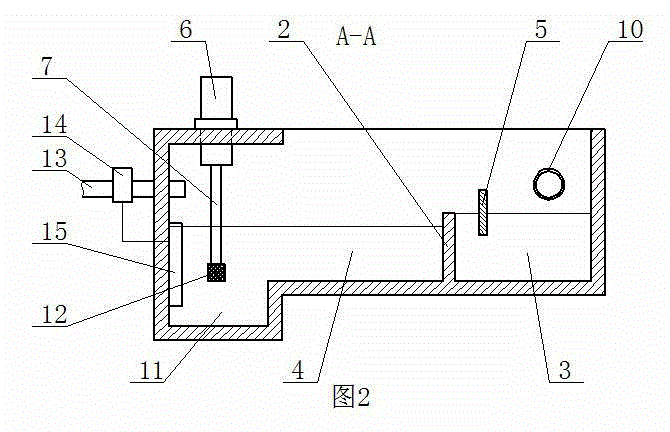

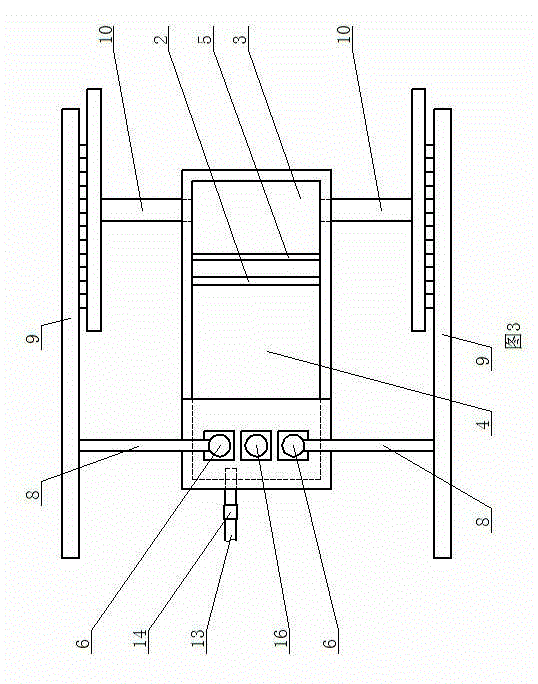

[0009] The emulsion circulation device of the present invention includes a circulation tank 1, an overflow weir 2 is arranged in the circulation tank 1, and the overflow weir 2 divides the circulation tank 1 into a sedimentation tank 3 and a purification tank 4, and a filter is installed in the sedimentation tank 3. Plate 5, the level of the upper end of the filter plate 5 is higher than the level of the upper end of the overflow weir 2, and the level of the lower end of the filter plate 5 is lower than the level of the upper end of the overflow weir 2. A circulating pump 6, a circulating pump is installed above the purification tank 4 The liquid inlet of 6 is connected to one end of the liquid suction pipe 7, and the other end of the liquid suction pipe 7 is located in the purification tank 4. The liquid outlet of the circulating pump 7 is connected with the steel production line 9 through the circulating liquid supply pipe 8. The circulation return pipe 10 is in communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com