Electromagnetic control method for directly restricting and controlling liquid level fluctuation of conducting metal fluid

A conductive metal, constraint control technology, applied in the field of electromagnetic processing and forming of materials, can solve the problems of constraining conductive metal fluid level fluctuations and propose a more universal method, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The copper direct conduction coil is used as the parallel direct conduction coil, and the specific parameters of the copper direct conduction coil are shown in Table 2:

[0034] Table 2 Specific parameters of copper direct conduction coil

[0035] copper coil

parameters

6.94×10 6 S / m

1

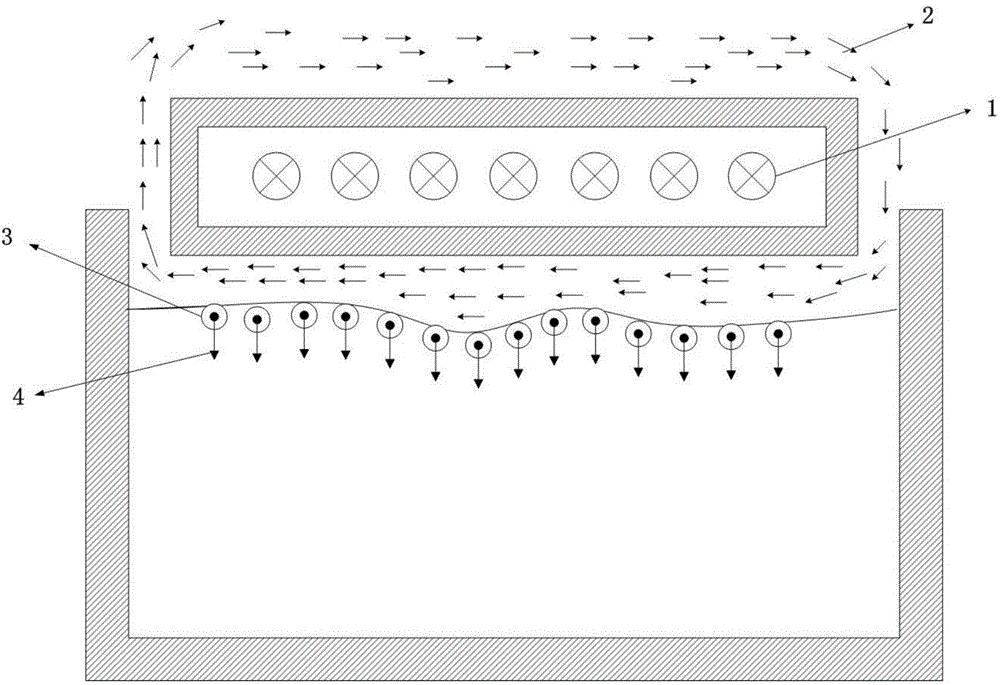

[0036] Such as figure 1 As shown, the parallel direct conduction coil 1 with 11 turns is arranged horizontally on the liquid surface of the conductive metal fluid that needs to control the fluctuation of the liquid level. The top view of the parallel direct conduction coil is as follows figure 2 shown.

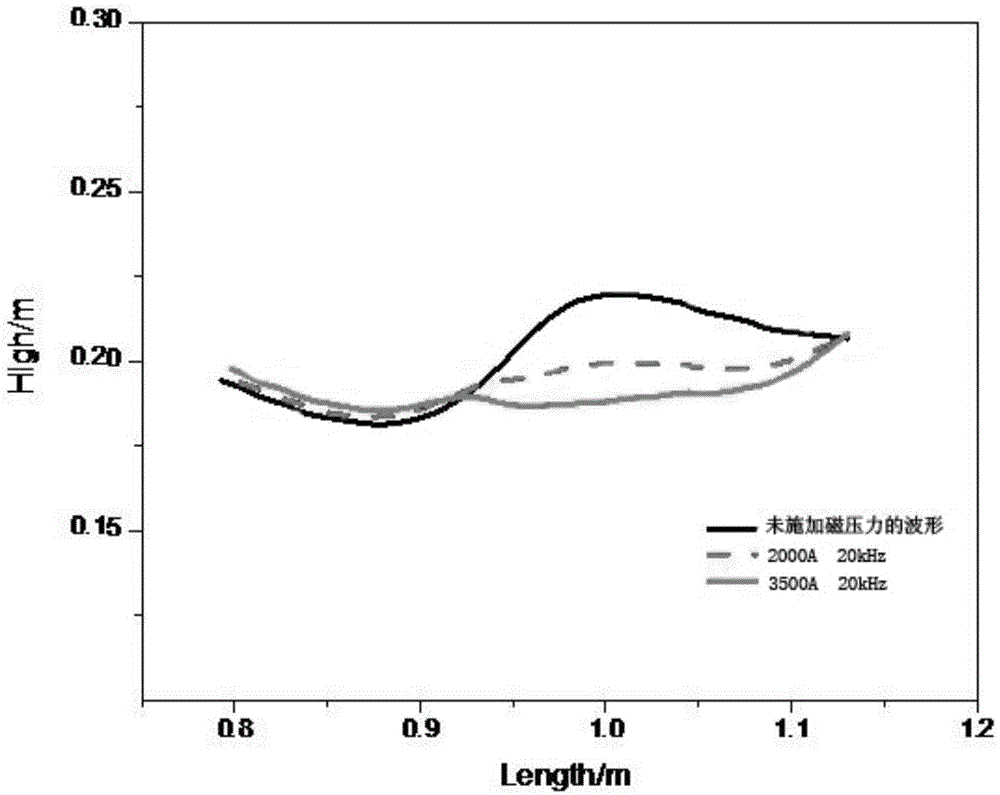

[0037] The current size is 2000A, the frequency is 20kHz harmonic AC and the frequency is 3500A, the frequency is 20kHz harmonic AC, and the height of the parallel direct coil from the conductive metal fluid surface is 10mm, so that the conductive metal fluid surface is in a horizontal direction In the al...

Embodiment 2

[0039] A copper disc-shaped conductor coil is used as the disc-shaped conductor coil. Such as Figure 4 As shown, a disk-shaped conductor coil 5 with 10 turns is arranged horizontally on the liquid surface of the conductive metal fluid that needs to control the fluctuation of the liquid level. The top view of the disk-shaped conductor coil is as follows Figure 5 shown.

[0040] The current size is 2000A, the frequency is 20kHz harmonic AC and the frequency is 3500A, the frequency is 50kHz harmonic AC, the height of the disc-shaped conductive coil from the liquid surface of the conductive metal fluid is 10mm, so that the liquid surface of the conductive metal fluid is in a horizontal direction In the alternating magnetic field 6, according to the action of electromagnetic induction, the alternating magnetic field generates an induced current 7 in the conductive metal fluid, and the induced current interacts with the alternating magnetic field to form a magnetic flux perpendic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com