Four-axle turn-mill combination vertical processing center

A vertical machining center, turning and milling technology, applied in metal processing equipment, metal processing machinery parts, tool holders, etc., can solve the problems of inability to turn workpieces, affect product accuracy, and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

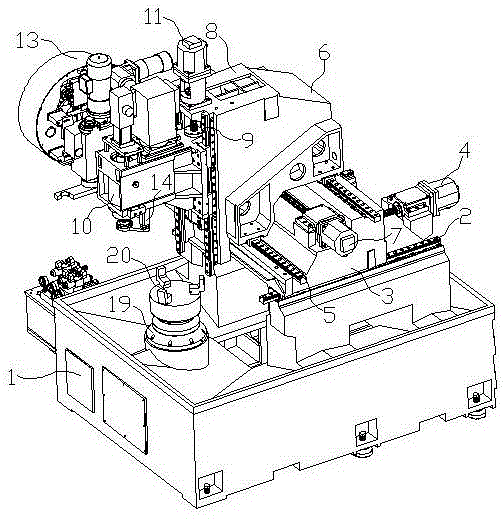

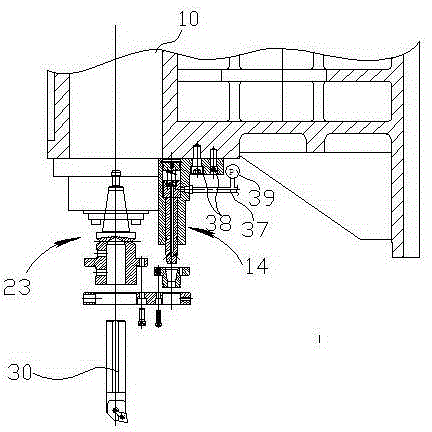

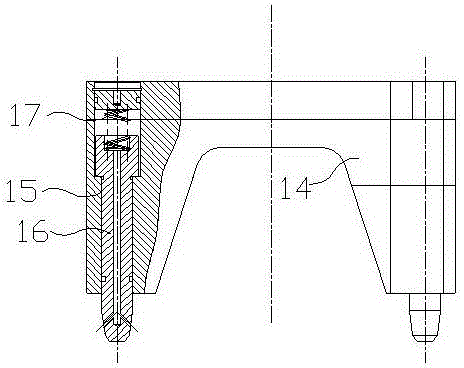

[0032] Figure 1~Figure 10 Among them, the four-axis turning-milling compound vertical machining center has a bed 1, and a horizontal longitudinal slideway 2 is provided on the rear of the bedside, and a longitudinal slide seat 3 that can slide on the longitudinal slideway is arranged on the longitudinal slideway, and the bed and the longitudinal slideway There is a longitudinal feed device 4 between the seats, a horizontal slideway 5 is arranged on the longitudinal slideway, and a horizontal slideway 6 that can slide on the horizontal slideway is arranged on the horizontal slideway, and there is a longitudinal feeder between the horizontal slideway and the longitudinal slideway. For the device 7, the positioning on the horizontal sliding seat is connected with a column 8, and the vertical slideway 9 perpendicular to the horizontal plane is arranged on the column. There is a main motor and a main shaft connected by a transmission device in the body. There is a vertical feed de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com