Reducer for translational mechanism

A translation mechanism and reducer technology, applied in mechanical equipment, grinding machines, metal processing equipment, etc., can solve the problems of wasting billet materials, affecting billet quality, and large manual cutting seams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

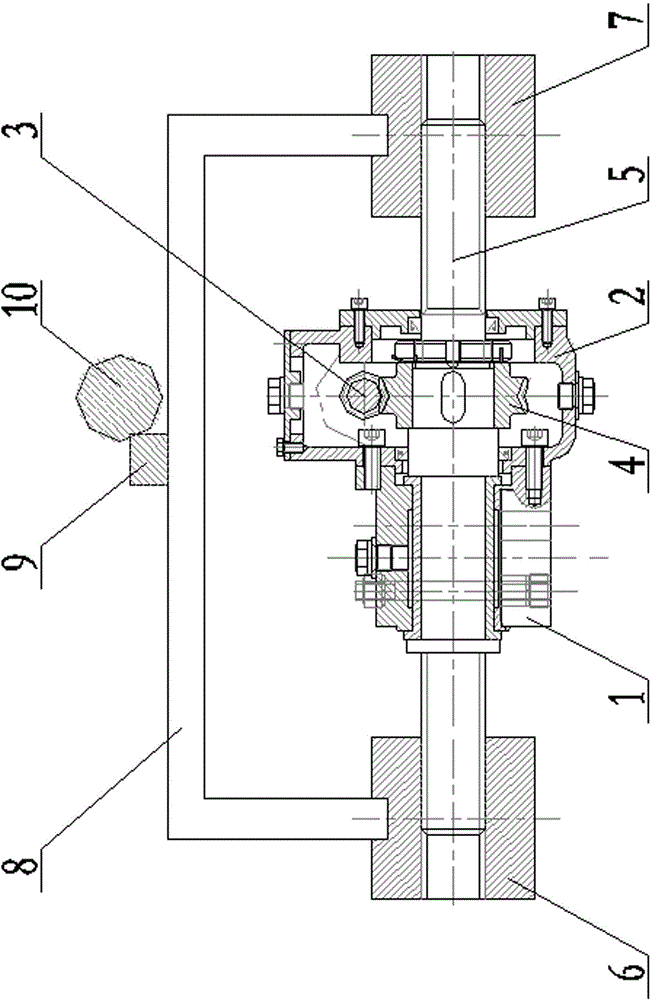

[0010] figure 1 As shown, a speed reducer for a translation mechanism includes a fixed seat 1, a box body 2, a worm 3, a worm wheel 4, a screw 5, a left nut 6, a right nut 7 and a crossbeam 8, and the crossbeam 8 is erected on the left and right nuts 6, 7 is in the state of driving the steel billet 9 on it towards or away from the cutting wheel 10, and the left and right nuts 6 and 7 are threadedly connected with the screw mandrel 5, and the screw mandrel 5 is fixedly connected to the fixed seat 1, and the fixed seat 1 is connected to the box The body 2 and the box body 2 are provided with a worm wheel 3 and a worm screw 4 that are self-locking and meshing with each other, and the worm wheel 4 is fixedly connected to the screw rod 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com