A kind of moso bamboo cutting control system

A control system and bamboo technology, which are used in agricultural machinery and implements, electric pruning saws, gardening, etc., can solve problems such as the inability to meet the needs of automated production and the inability to automatically cut out waste, so as to improve the effective utilization rate and avoid waste. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the technical solution of the present invention will be described in detail through specific examples.

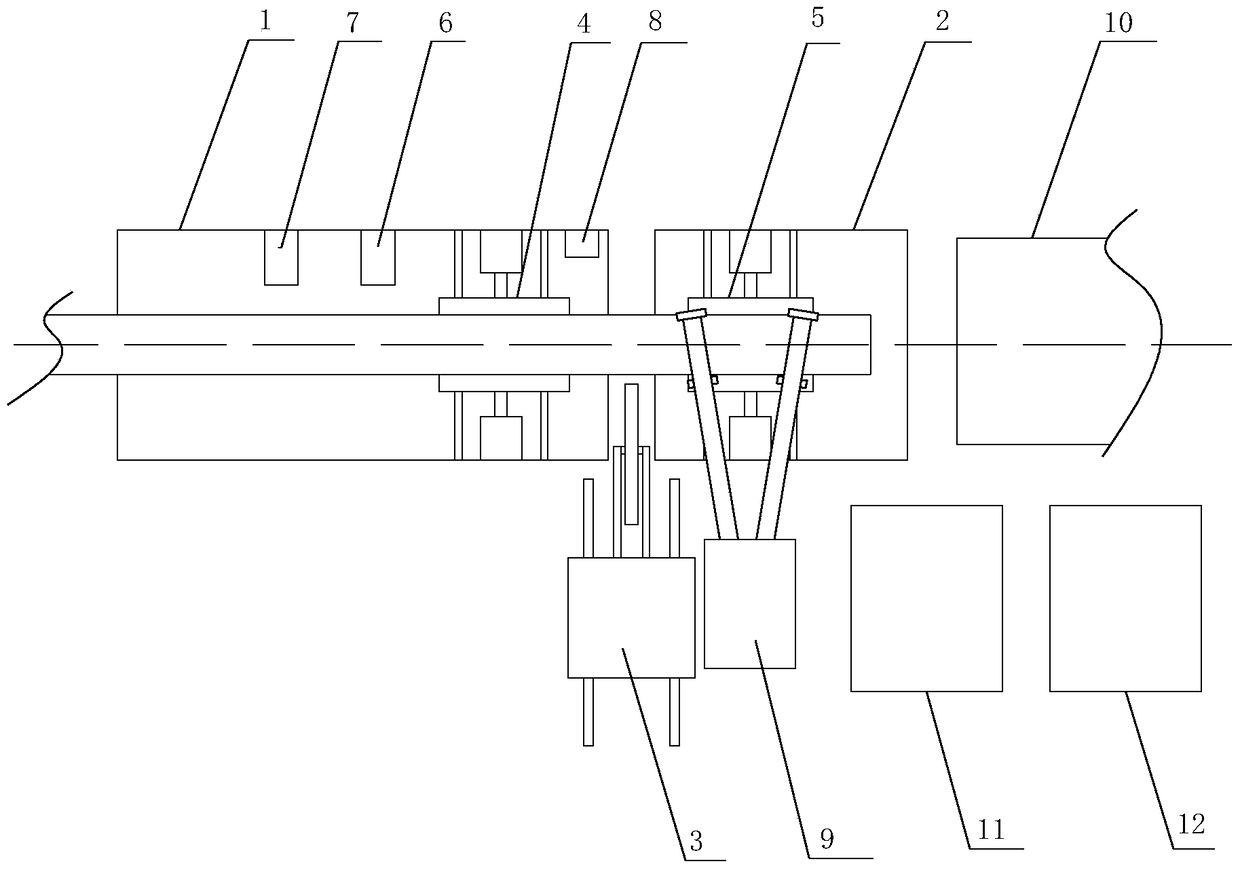

[0027] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a moso bamboo cutting control system proposed by the present invention.

[0028] refer to figure 1 , a kind of moso bamboo cutting control system that the embodiment of the present invention proposes, comprises: the first supporting table 1, the second supporting table 2, cutting device 3, the first clamping device 4, the second clamping device 5, manipulator 9, output Device 10, waste collection container 11, defective product collection container 12, first sensor 6, second sensor 7, timer 8 and control device, wherein:

[0029] The first support platform 1 and the second support platform 2 are arranged side by side, and the first support platform 1 and the second support platform 2 are in the same straight line, and a gap is reserved between the first support platform 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com