A hollow self-cooling grinding disc and cooling method

A self-cooling, grinding disc technology, applied in grinding machines, abrasives, grinding/polishing equipment, etc., can solve the problems of easy damage of cooling water pipes, low utilization rate of cooling water, pollution of laboratory environment, etc., to avoid short-circuit phenomenon and Personal injury, convenient placement and removal of samples, and the effect of accelerating the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

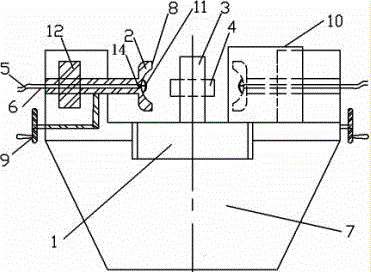

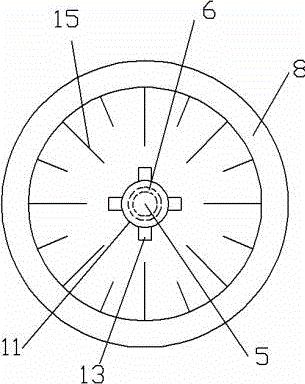

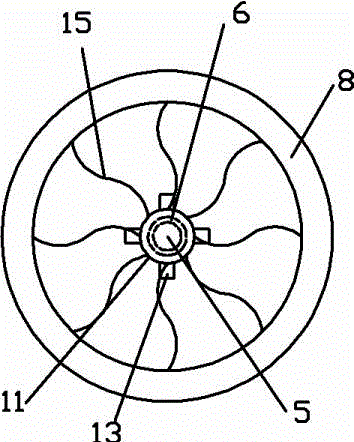

[0022] Such as figure 1 As shown, a hollow self-cooling grinding disc includes a grinding disc head (2), a rotating shaft (6) integrated with the grinding disc head, and a cooling water pipe (5). The periphery of the grinding disc head (2) is a circular grinding disc surface ( 8), the inner side of the grinding disc surface (8) is a circular arc concave surface, the rotating shaft (6) is coaxial with the grinding disc head (2), and the middle part of the rotating shaft (6) and the grinding disc head (2) are both Hollow structure, the cooling water pipe (5) is passed through the hollow structure, the water inlet end of the cooling water pipe (5) is set on the side of the rotating shaft (6), and the water outlet end is set on the side of the grinding head (2), the cooling The water outlet end of the water pipe (5) is provided with a shower (14); the outer side of the disc head (2) is connected with an arc concave baffle (11), and the arc concave baffle (11) is fixed on the The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap