Magnetic-isolating material and flexible treatment method thereof

A processing method and magnetic isolation technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of affecting the service life of tools, improper control, scrapping of tool molds, etc., to improve work efficiency, Good bending effect, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

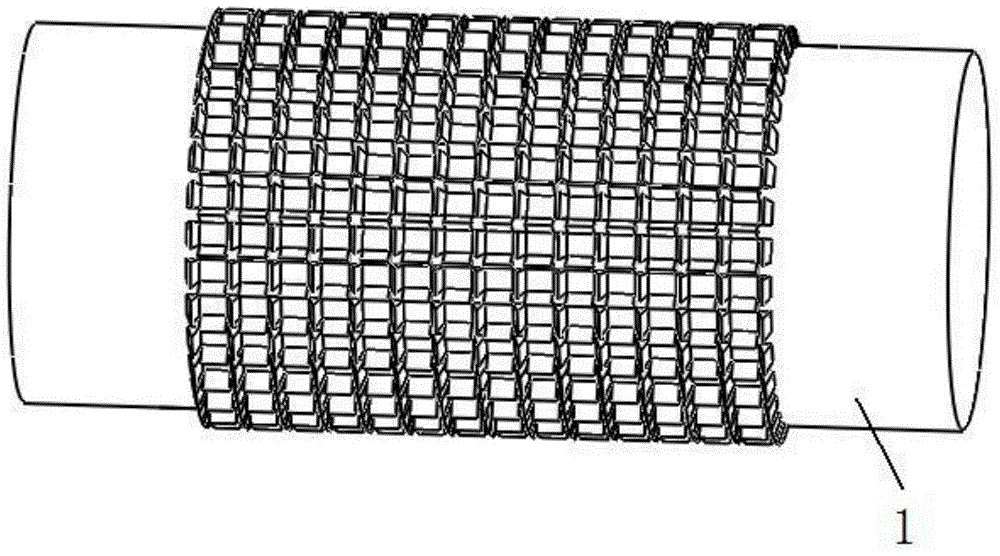

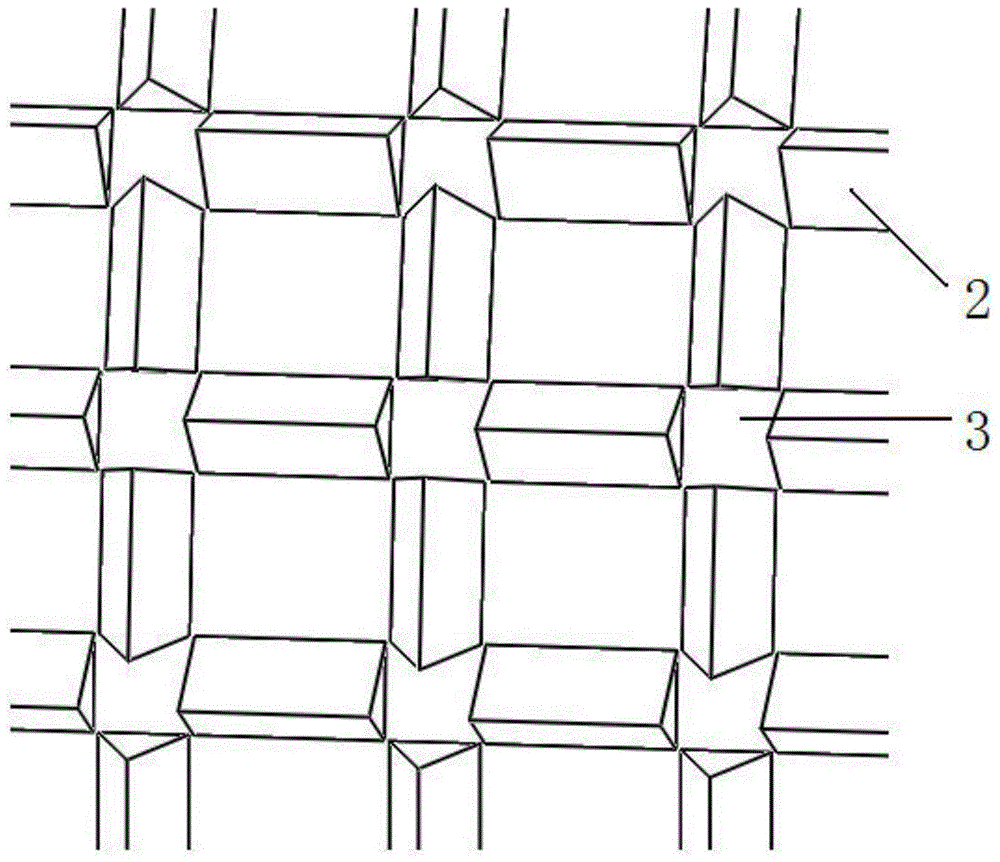

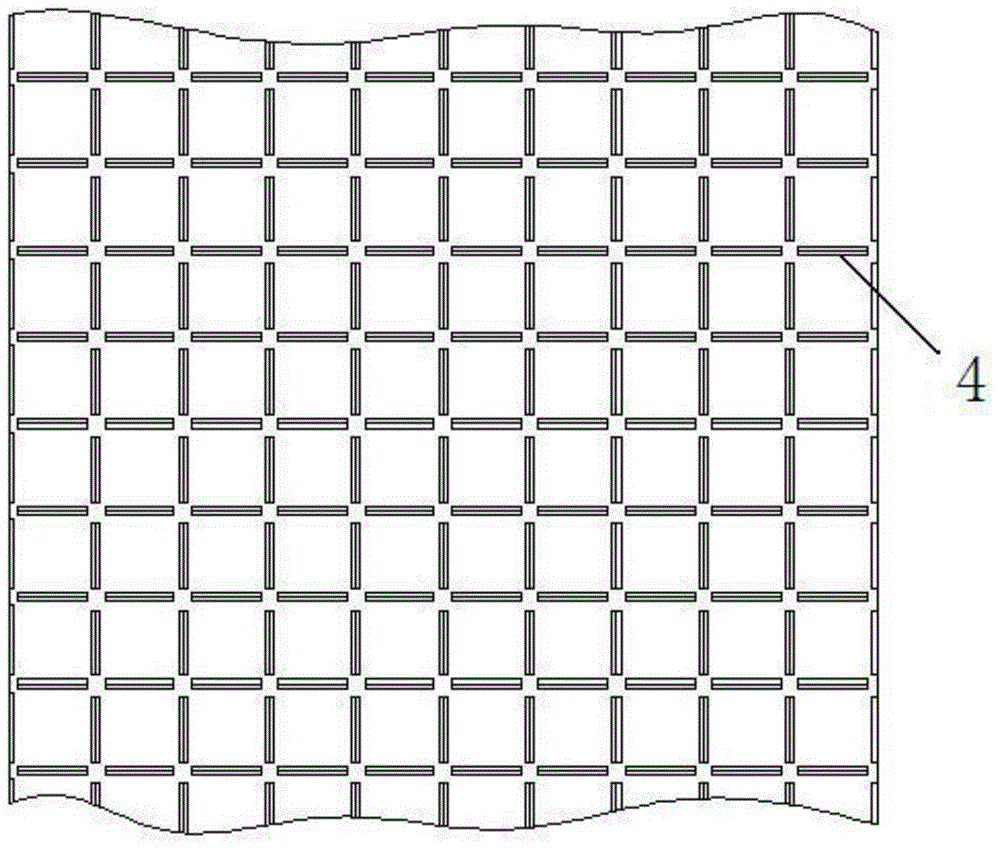

[0033]First, nickel-copper-zinc ferrite powder, solvent (ethanol and toluene or ethanol and xylene binary mixture), binder (polyvinyl butyral (PVB)), plasticizer (dibutyl phthalate Ester (DBP)) and other additives are ball milled and mixed into a slurry according to a certain ratio. The slurry is tape-cast and dried at 40°C to prepare a ferrite green sheet with a thickness of 0.152mm, such as figure 1 As shown, a circular roller die 1 with a diameter of 85mm is used, such as figure 2 As shown, the distance between two adjacent triangular section convex strips 2 is 2.5mm, the height of the triangular section convex strips is 1.2mm, the apex angle of the triangular section convex strips is 25 degrees, and the intersection of the triangular section convex strips 2 The gap 3 is 0.5mm, rolling one side of the ferrite green sheet, such as image 3 As shown, a V-shaped groove 4 with a depth of 0.03 mm is formed on the surface of the ferrite sheet, and the depth of the V-shaped groo...

Embodiment 2

[0035] Using the same method as Example 1 to prepare a ferrite green sheet with a thickness of 0.724 mm, a circular roller die 1 with a diameter of 105 mm is used, the distance between two adjacent triangular section convex lines 2 is 3.6 mm, and the height of the triangular section convex lines is 1.5 mm. mm, the apex angle of the triangular section convex strip is 35 degrees, the gap 3 at the intersection of the triangular section convex strip 2 is 1mm, and one side of the ferrite green sheet is rolled to form a depth of 0.23mm V-shaped groove 4, the prepared ferrite green sheet is fired at 965°C to obtain a well-fired ferrite fired sheet, and one side of the ferrite fired sheet is bonded with a PET protective film Or double-sided tape, the other side is glued with double-sided tape, and then it is rolled by a steel rod with a diameter of 6mm, and the ferrite fired sheet is divided into many small square pieces along the V-shaped groove 4 to form a Magnetic isolation materia...

Embodiment 3

[0037] Use the same method as in Example 1 to prepare a ferrite green sheet with a thickness of 0.072mm, directly burn it at 945°C to form a ferrite fired sheet, and then glue a PET protective film or double-layered ferrite sheet on one side of the ferrite fired sheet. Adhesive tape on the other side and double-sided tape on the other side, and then rolled by a steel rod with a diameter of 6mm, the ferrite fired sheet is randomly broken into many pieces, so that the final magnetic isolation material has a good bending effect. The Agilent 4991A impedance meter tests the complex permeability. When the frequency is 13.56MHz, the measured complex permeability μ′=138.4, μ″=1.86.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com