Forming process for vertical shared exhaust ducts

A molding process and exhaust duct technology, which is applied to vertical pipes, building components, buildings, etc., can solve the problems of insufficient vertical shared exhaust ducts, reduce storage yard and transportation costs, reduce safety risks, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

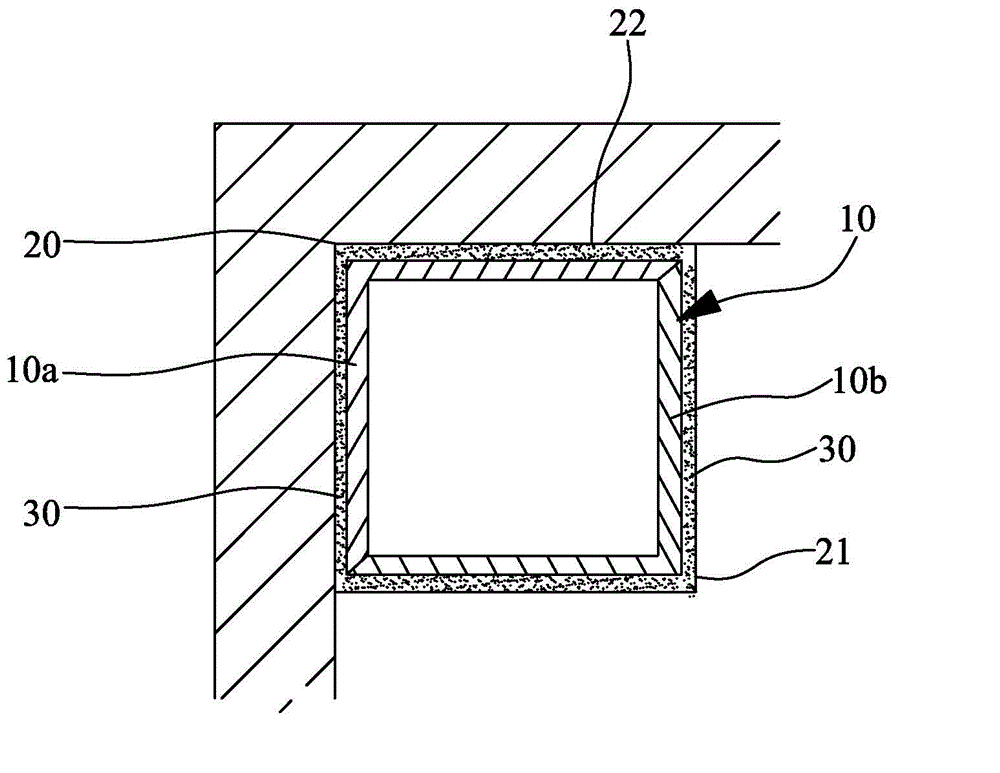

[0044] figure 1 , Is a top view of the vertical shared exhaust duct provided by the first embodiment of the present invention. The vertical shared exhaust duct 10 is formed in the corresponding preset hole 21 on the floor of the inner corner 20 of the floor room. When viewed in cross section, the vertical shared exhaust duct is formed by butting two L-shaped thin-walled members, one of which is L-shaped The thin-walled member is provided with an air inlet (not shown in the figure) for installing a check valve. Here, for ease of description, the L-shaped thin-walled member located on the inner side is named the first L-shaped thin-walled structure 10a, and the L-shaped thin-walled member located on the outer side is named the second L-shaped thin-walled member 10b. Here, the first L-shaped thin-walled member 10a and the second L-shaped thin-walled member 10b have the same structure, and the "first" and "second" here are only used to distinguish the inside and the outside.

[0045...

Embodiment 2

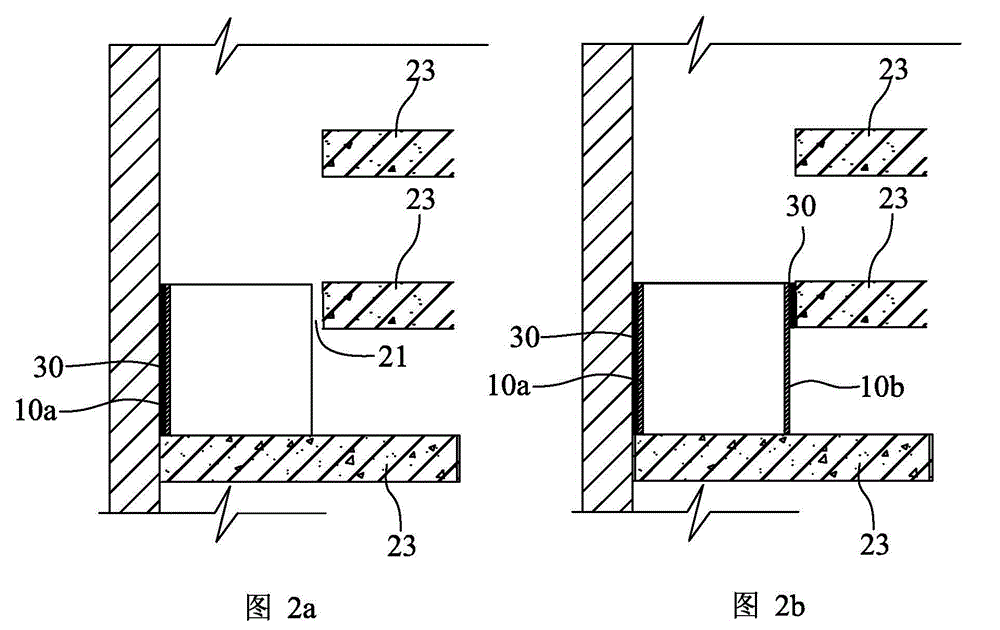

[0058] Figure 5a to Figure 5d , Is a schematic cross-sectional view of the forming process of the vertical shared exhaust passage provided in the second embodiment of the present invention. This embodiment also takes the vertical shared exhaust duct molding between two floors in a residence as an example for description. The molding processes of other floors are the same as in this embodiment, and will not be described in detail here. Moreover, this embodiment is described by taking as an example that the exhaust ducts in each floor are formed by butting and forming a first L-shaped thin-walled structure 10a and a second L-shaped thin-walled member 10b.

[0059] Figure 5a , The first L-shaped thin-walled member 10a is attached to the two wall surfaces 22 of the internal corner 20 of the room on the lower floor. In order to ensure the reliability of the close installation, the two outer wall surfaces of the first L-shaped thin-walled member 30a and the two wall surfaces 22 of th...

Embodiment 3

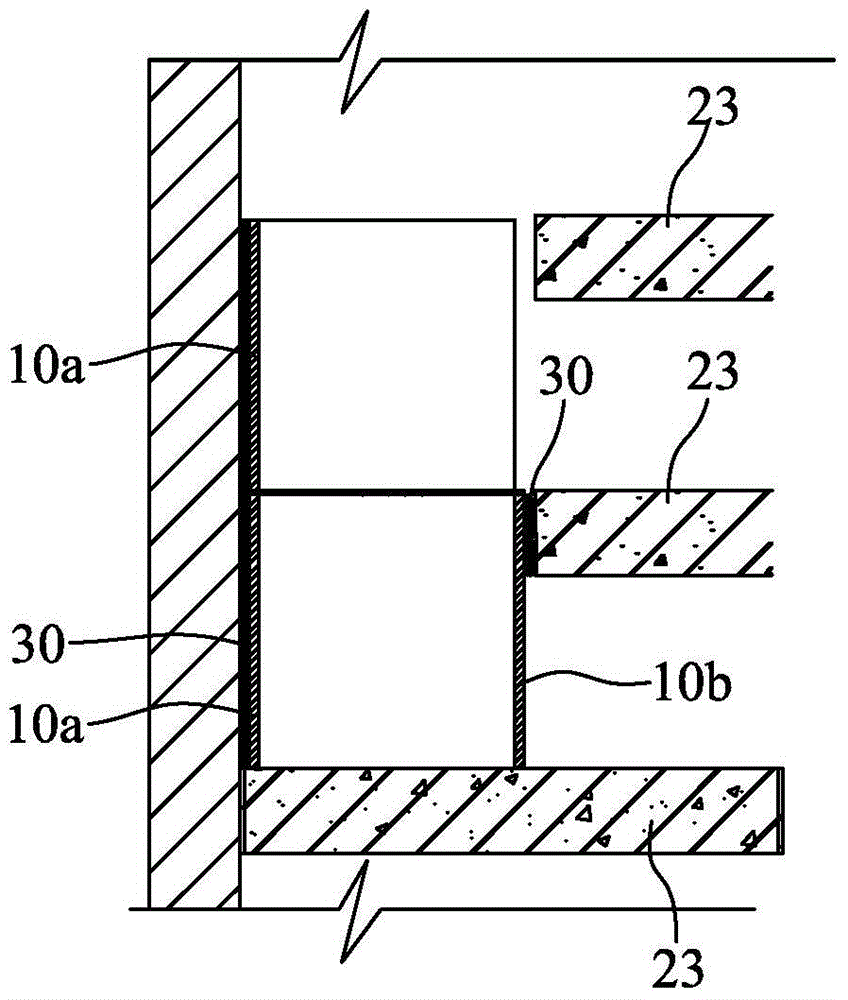

[0066] Image 6 , Is a longitudinal cross-sectional view of the vertical shared exhaust passage provided in the third embodiment of the present invention. In this embodiment, the exhaust duct on each floor is formed by butting two first L-shaped thin-walled members and two second L-shaped thin-walled members. In this way, compared to the first embodiment, the weight of each L-shaped thin-walled member is lighter, and it is easier to handle and install. Here, one floor is taken as an example for description, and the other floors are the same, so I won’t repeat them here. When forming the exhaust duct of the floor, first perform step S1, first fix the first first L-shaped thin-walled member 10a, and then perform step S2, that is, fix the first first L-shaped thin-walled member 10a Butt the first second L-shaped thin-walled member 10b, then repeat step S1, superimpose the second first L-shaped thin-walled member 10a on the first first L-shaped thin-walled member 10a, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com