Land wheel driving mechanism

A transmission mechanism and ground wheel technology, which is applied to transmission parts, mechanical equipment, belts/chains/gears, etc., can solve the problems of the chain transmission mechanism being easy to clip grass, affecting the service life, affecting the work efficiency, etc., and achieving long service life. , mentioned the effect of work efficiency and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described below in conjunction with embodiment and accompanying drawing.

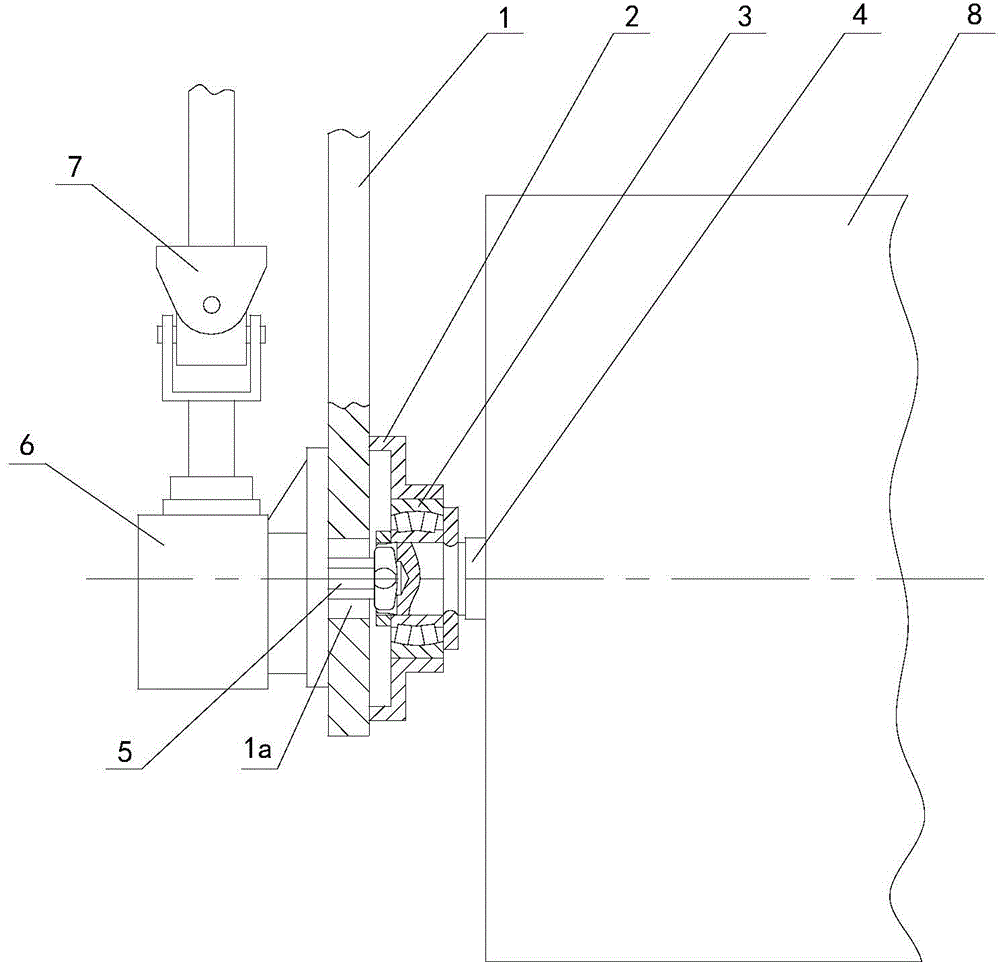

[0013] see figure 1

[0014] The ground wheel transmission mechanism provided by the present invention has a support frame 1, and the gear box 6 and the bearing seat 2 which are arranged oppositely are respectively fixed on the two sides of the support frame 1, and the support frame 1 is provided with the corresponding gear box and the bearing seat. The through hole 1a is equipped with a self-aligning bearing 3 in the bearing seat 2, and the shaft head 4 is installed on the self-aligning bearing 3. The input shaft of the gearbox 6 is connected with a transmission rod 5, and the transmission rod 5 passes through the through hole 1a and the shaft head 4 form a transmission fit. The gear box 6 is a commercially available product.

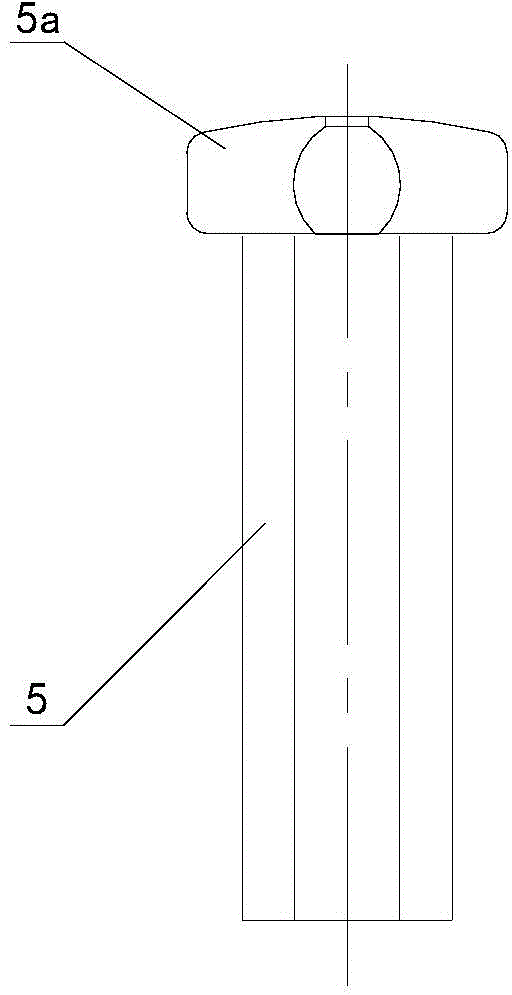

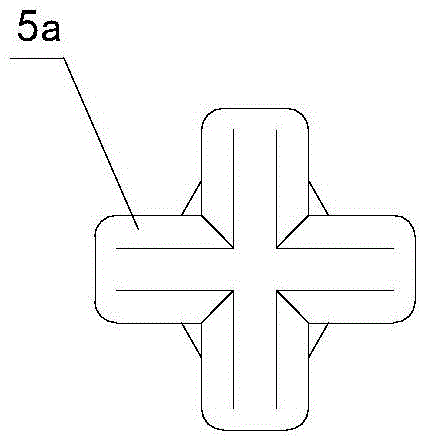

[0015] see Figure 1 to Figure 5

[0016] In this embodiment, the rod body of the transmission rod 5 is in the shape of a hexagonal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com