Oilproof hose coupler

A kind of hose joint, oil-resistant technology, applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of poor use strength, poor reliability, poor matching, etc., to achieve good strength and toughness, universal Good performance and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in combination with specific embodiments.

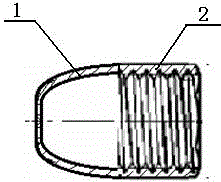

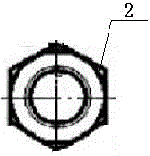

[0011] see figure 1 , figure 2 , an oil-resistant hose joint, including a screw body 1 and a nut 2 sleeved on it, one end of the screw body 1 is provided with an external thread that matches the nut 2, the other end of the screw body 1 is in the shape of a smooth arc, and the nut 2 The outer diameter is consistent with the largest diameter end of the screw body 1; the nut 2 is a hexagonal nut.

[0012] When in use, the arc end of the screw body 1 is inserted into the object to be connected, and then the nut 2 is tightened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com