Bagasse fired boiler

A boiler and bagasse technology, which is applied in the field of boilers using bagasse as fuel, can solve problems such as boiler explosion and blockage of bagasse-burning boiler grate holes, and achieve the effects of ensuring normal operation, improving economy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

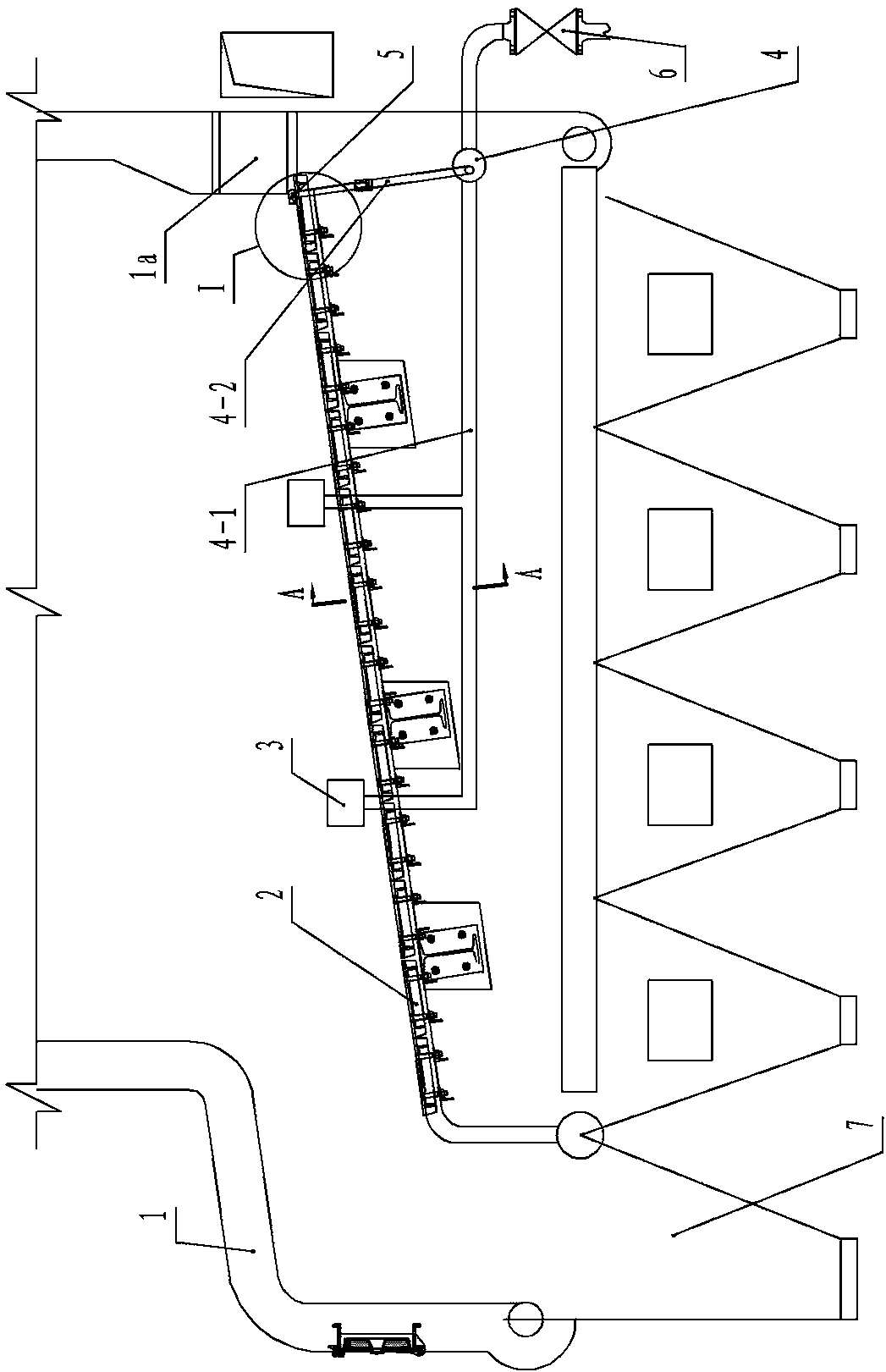

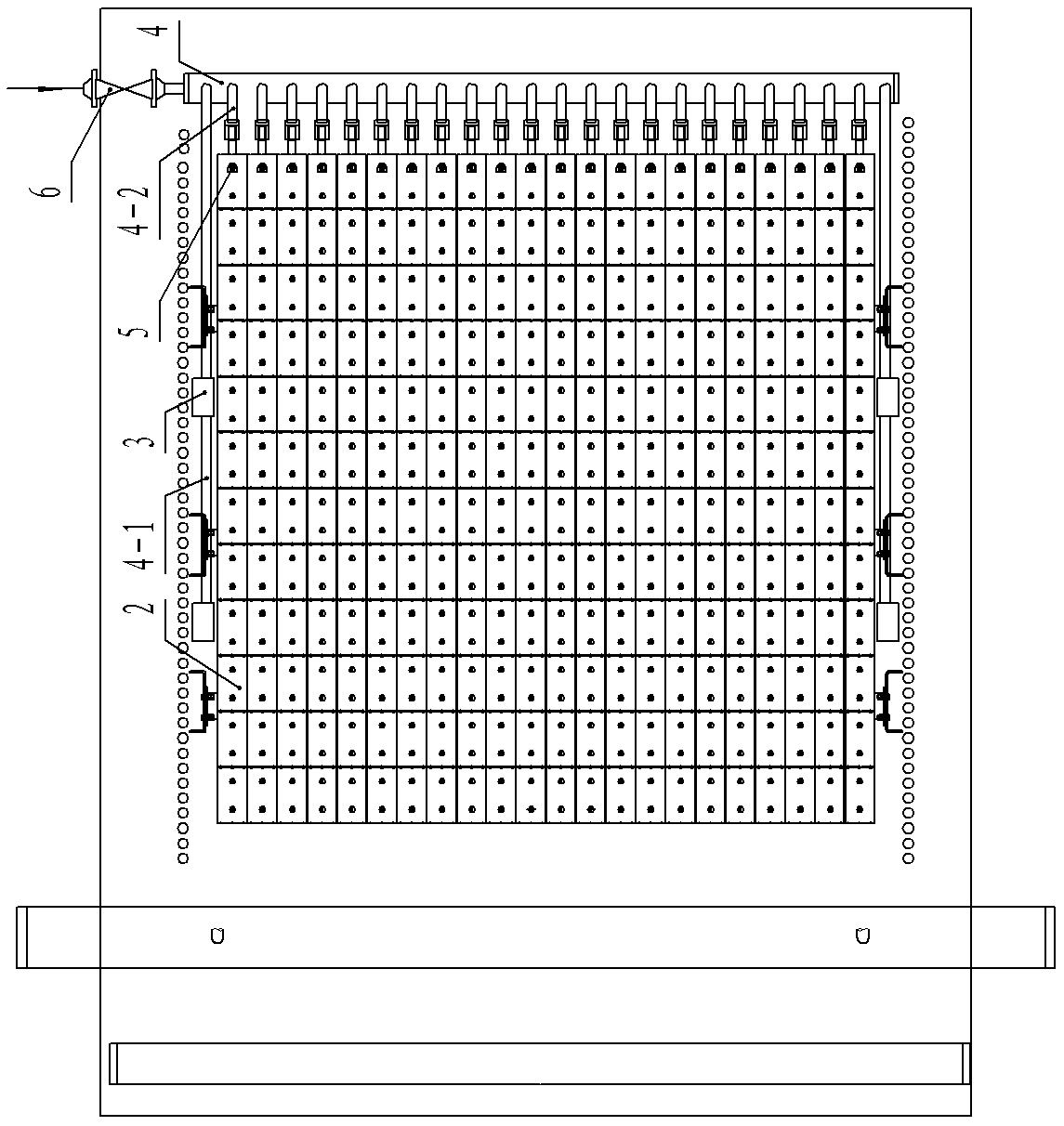

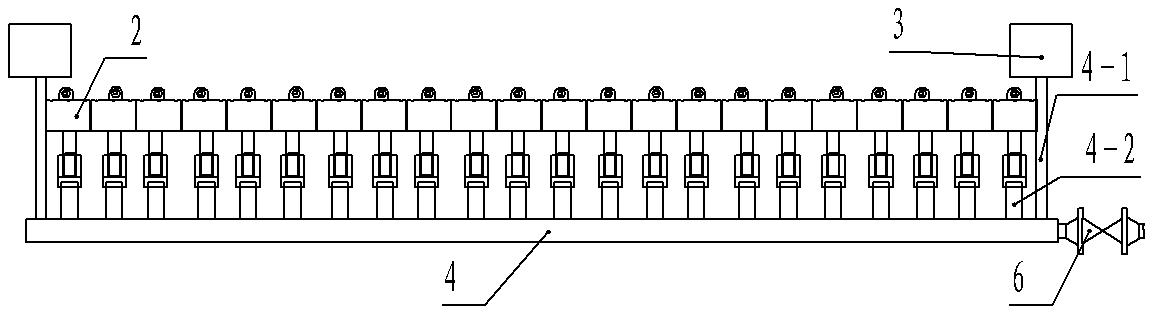

[0016] figure 1 , figure 2 , image 3 The shown bagasse-burning boiler includes a boiler body 1, which is provided with a feed port 1a communicating with the combustion chamber, and a fire grate 2 is arranged in the combustion chamber, and the fire grate 2 is spliced by a plurality of fire grate pieces with through holes. There are gaps between the grate pieces, the grate 2 is arranged obliquely, and the angle between the grate 2 and the horizontal direction is 5°; the front end of the grate 2 is close to the feed port 1a and is higher than the end of the grate 2, and the grate The bottom of the 2 ends is provided with a receiving hopper 7, such as Figure 4 There are 22 nozzles 5 connected to the main gas pipe 4 through the nozzle 4-2 at the front end of the grate 2, and the nozzles 5 face the end of the fire grate; 4 connected 4 acoustic soot cleaners 3, the main gas pipe 4 is connected to the gas tank, and the sonic soot cleaner 3 is connected to the controller throug...

Embodiment 2

[0018] The angle between the fire grate 2 and the horizontal direction is 10°; the rest are the same as in the first embodiment.

[0019] Both sides of the grate of the present invention are equipped with sonic soot cleaners, and nozzles are added to the front end of the grate. When the boiler is working, it is automatically controlled by an electromagnetic valve. The sonic soot cleaner converts the compressed air potential energy into low-frequency sound energy, and passes The medium transmits the sound energy to the sand and ash carried during the bagasse burning process, so that the sound waves will have the effect of "sound-induced fatigue" on the sand and ash, causing its structure to be destroyed due to fatigue; at the same time, the nozzle is controlled to open, and the The sediment is sprayed out without clogging the grate holes. The sonic soot cleaner 3 of this embodiment starts once every 20 minutes and works for 10 seconds each time, which ensures the normal operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com