A moving seal for a preheating furnace

A sealing element and preheating furnace technology, applied in the field of high temperature sealing, can solve the problems of aggravating the load of the movable stage, increasing the occurrence of accidents, adversely affecting the stability of the equipment, etc., so as to improve the production quality, avoid water leakage accidents, and avoid direct heat radiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

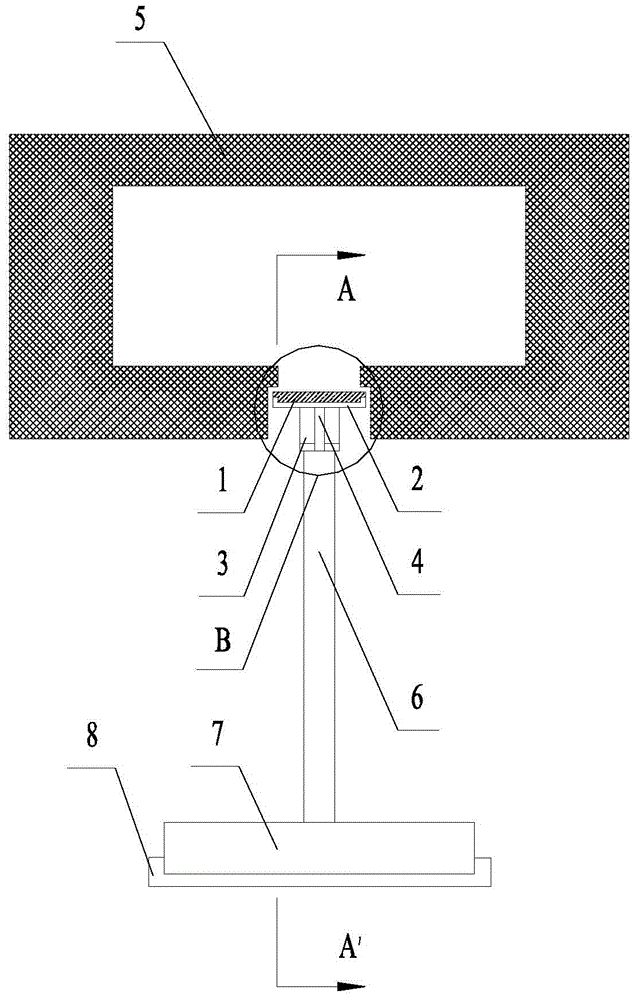

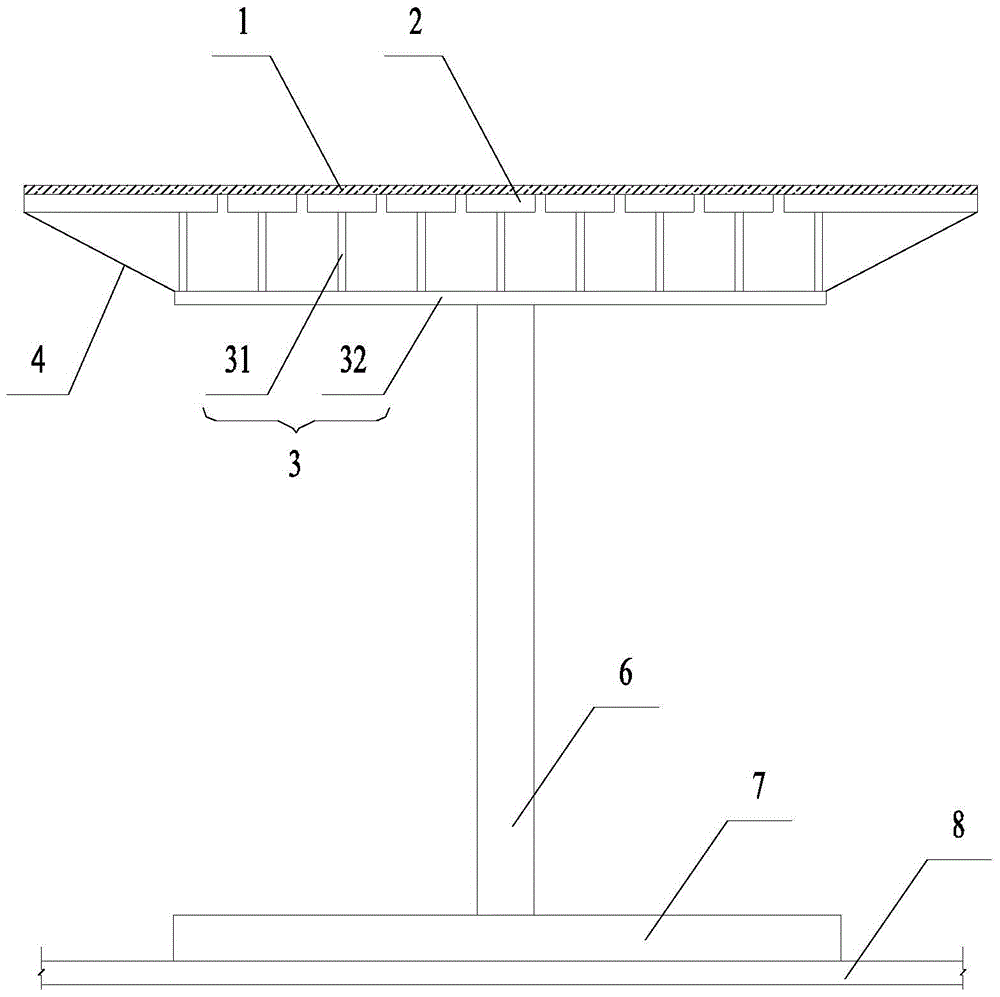

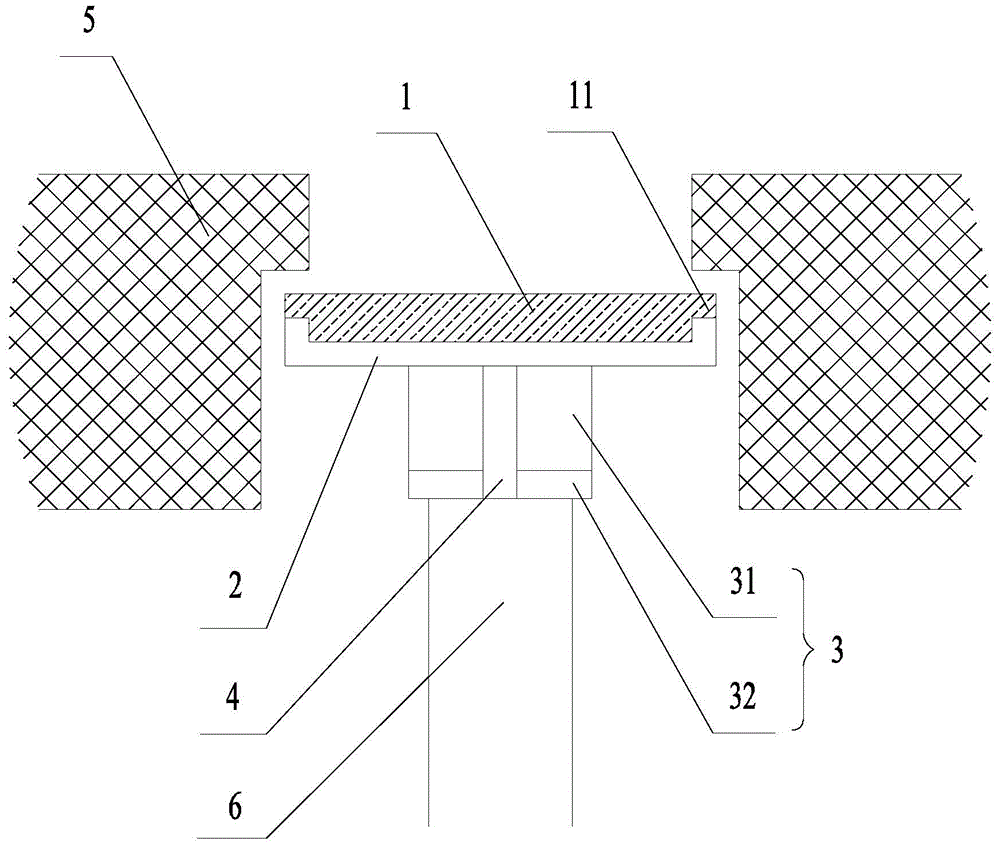

[0024] like figure 1 and figure 2 As shown, the present invention provides a moving seal of the preheating furnace, which is arranged at the furnace mouth of the preheating furnace 5, and is connected with the movable platform 7 through the connecting shaft 6, and the movable platform 7 is slidably arranged on the ground track 8, and drive the moving seal to move back and forth along the length of the furnace mouth. The moving seal includes a heat insulating board 1, the bottom of which is wrapped by a plurality of U-shaped grooves 2, and the bottom of the U-shaped groove 2 is connected with a connecting shaft 6 through a bracket 3, and the bracket 3 Comprising a plurality of vertical bars 31 and a cross bar 32, the bottom of each U-shaped groove 2 is correspondingly connected to a vertical bar 31, and the bottoms of all vertical bars 31 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com