Method for detecting gear meshing nominal clearance

A detection method, gear measurement technology, applied in the direction of mechanical clearance measurement, etc., can solve the problems of time-consuming and laborious measurement, high measurement cost, inaccuracy, etc., and achieve the effect of simple and reliable measurement method and small measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

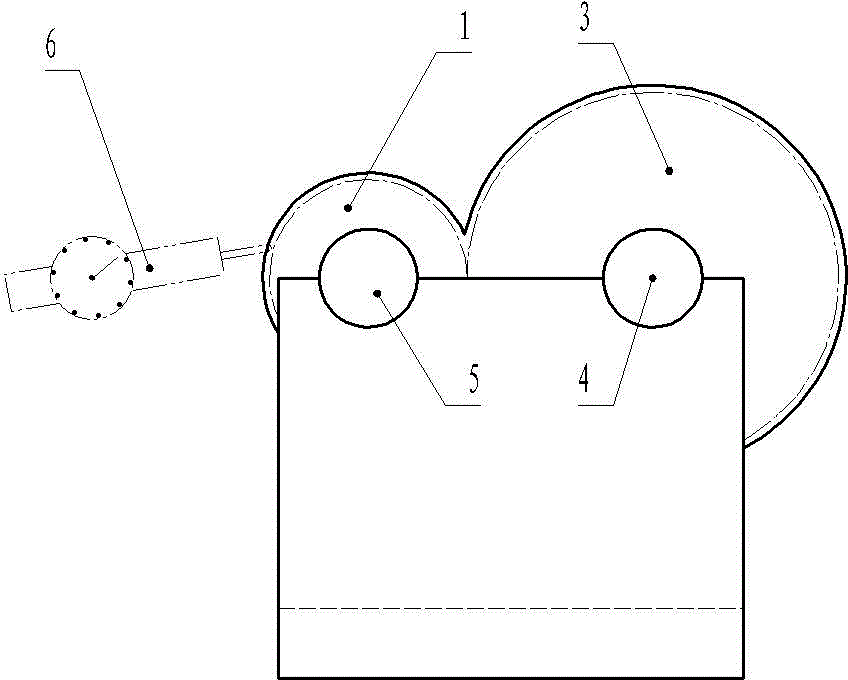

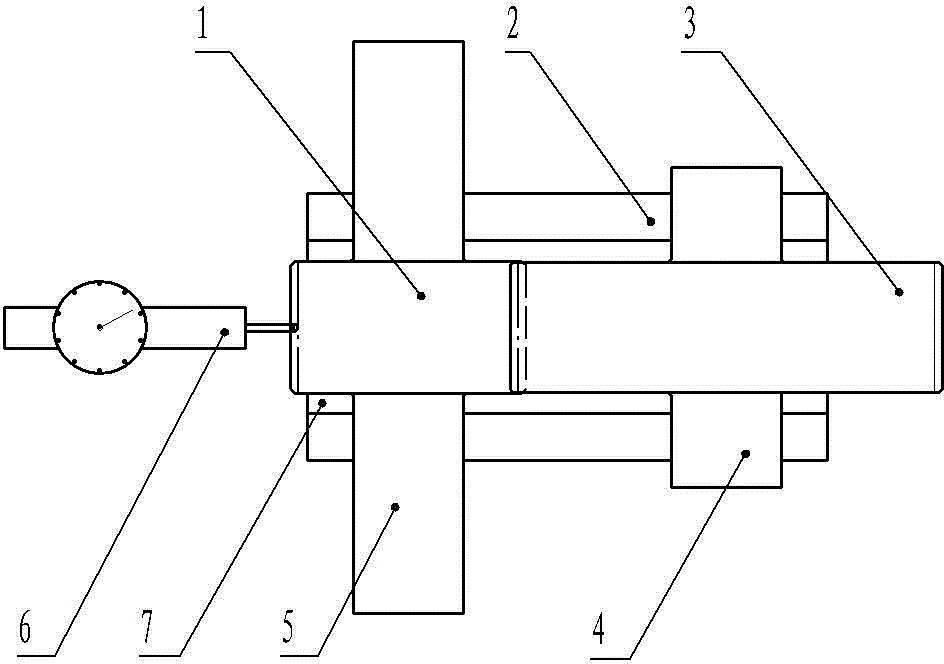

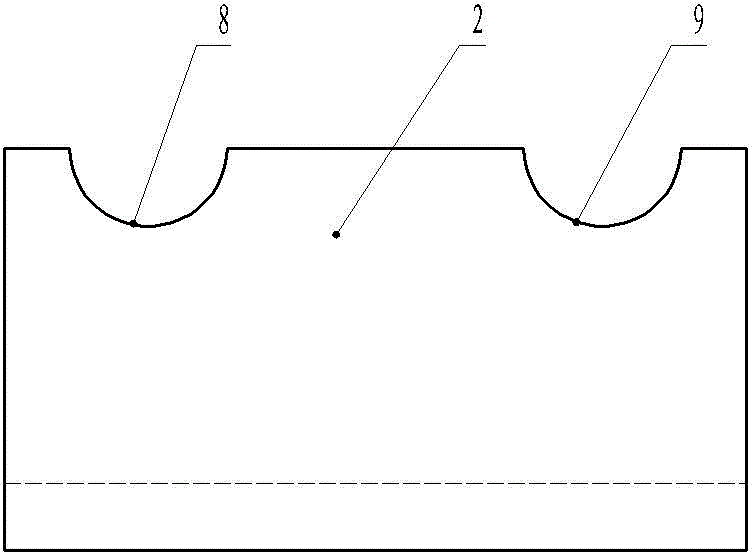

[0016] The first gear 1 and the second gear 3 are a pair of gears, and the detection method for the gear meshing normal clearance is to use such as image 3 Shown measuring device, this measuring device comprises two supporting plates 2 arranged in parallel and a bottom plate 7 connected to the lower parts of the two supporting plates 2, and the first concaves arranged coaxially are arranged on the top surfaces of the two supporting plates 2. Groove 8 and second groove 9; The first groove 8 and the second groove 9 are semicircular grooves arranged in parallel, and the distance between the axes of the two semicircular grooves is the first gear 1 and the second The sum of the pitch circle radii of the second gear 3;

[0017] The gear meshing normal backlash detection method includes the following steps:

[0018] A. Set the first gear 1 and the second gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com