Measuring method for additive manufacturing powder bed quality

A measurement method and additive manufacturing technology, applied in the direction of additive manufacturing, processing and manufacturing, manufacturing tools, etc., can solve problems such as the inability to control the uniformity of the powder layer thickness, the poor quality of molded parts, and the lack of scientific measurement methods for the thickness of the powder layer. , to achieve the effect of improving the quality of additive manufacturing powder bed, convenient operation, and simple and reliable measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

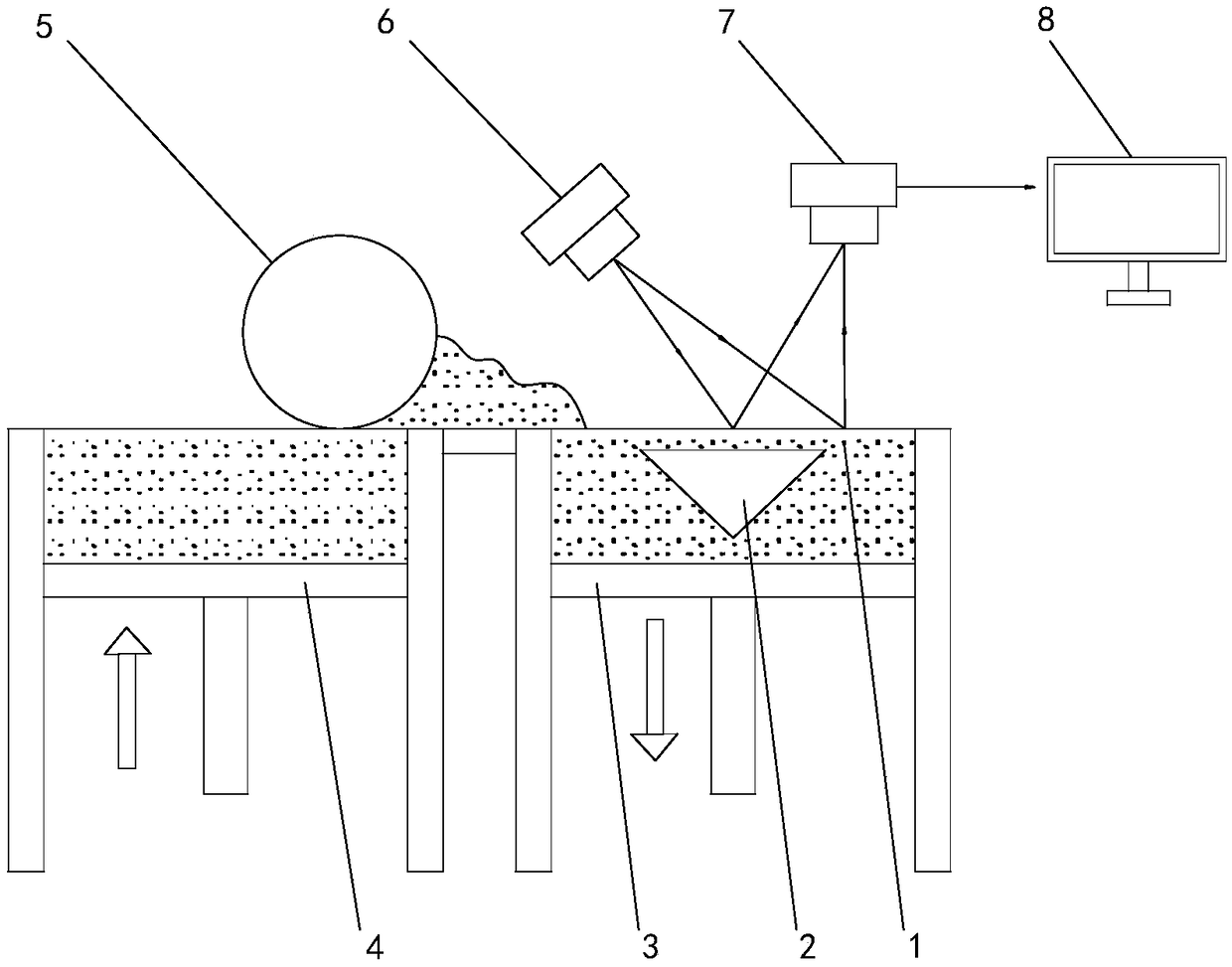

[0019] Please check figure 1 , the present embodiment takes nylon powder as object, and its measuring method is as follows:

[0020] The following devices are used: powder feeding cylinder 4, powder spreading roller 5, forming cylinder 3, motor assembly, light source transmitter 6, camera 7, image processing and display system 8;

[0021] The powder feeding cylinder 4 and the forming cylinder 3 are arranged side by side, and the upper edges of the two are flushly connected to form a workbench. The bottom of the powder feeding cylinder 4 is movable in the vertical direction to adjust the capacity of the powder feeding cylinder 4. The forming cylinder 3 is used to form the powder bed 1, and the forming part 2 is arranged in the forming cylinder 3, and the bottom of the forming cylinder 3 is movable in the vertical direction for adjusting the capacity of the forming cylinder 3;

[0022] The powder spreading roller 5 is arranged on the top of the powder feeding cylinder 4, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com