A monitoring method for efficient and safe operation of belt conveyors in coal mine working faces

A belt conveyor, safe operation technology, used in conveyor control devices, conveyor objects, volume measurement and fluid conveying, etc., can solve the problem of low calculation accuracy of instantaneous cross-sectional area, low detection accuracy, and low automation. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] like figure 1 , figure 2 and Figure 4 As shown, the efficient and safe operation monitoring method of belt conveyor in coal mine working face of the present invention comprises the following steps:

[0068] Step 1. Arrange hardware devices for monitoring. The specific process is:

[0069] Step 101. Arrange the visual sensor and the crusher on the transfer machine of the coal mine face, and make the visual sensor face the coal block measurement area on the transfer machine, so that the crusher is located in the middle of the visual sensor and the belt conveyor; a square black and white grid will be printed Place the calibration plate directly in front of the visual sensor, and make the calibration plate parallel to the plane of the coal block to be measured;

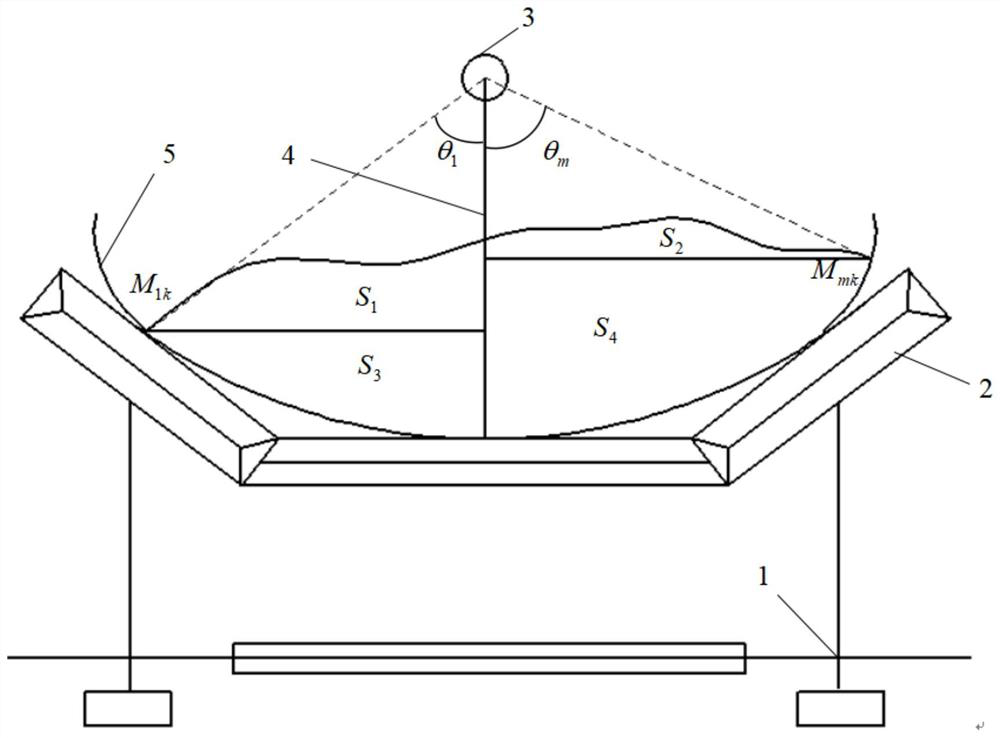

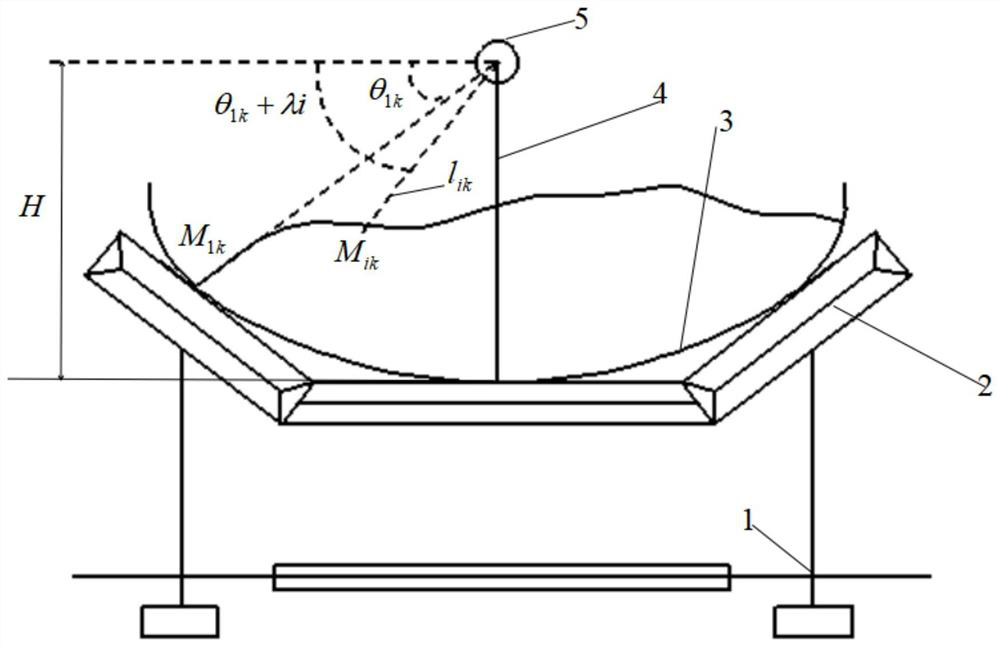

[0070] Step 102, installing the laser radar 5 at a position of H above the middle position of the belt conveyor belt 3, and making the scanning plane of the laser radar 5 perpendicular to the direction in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com