Method and system of performing interference testing on aspheric surface optical element

An interference system and optical element technology, used in diffractive optical elements transmitted by test and reference beams multiple times, interference test field, can solve problems such as difficulty of test beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

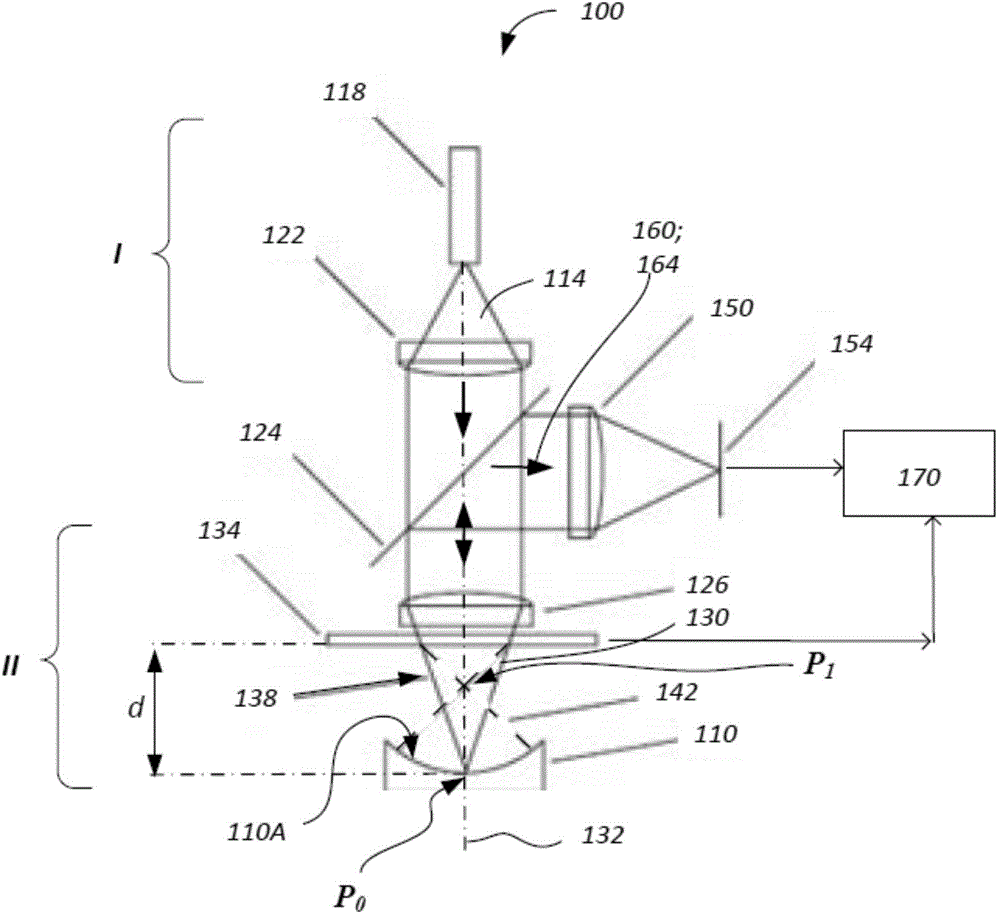

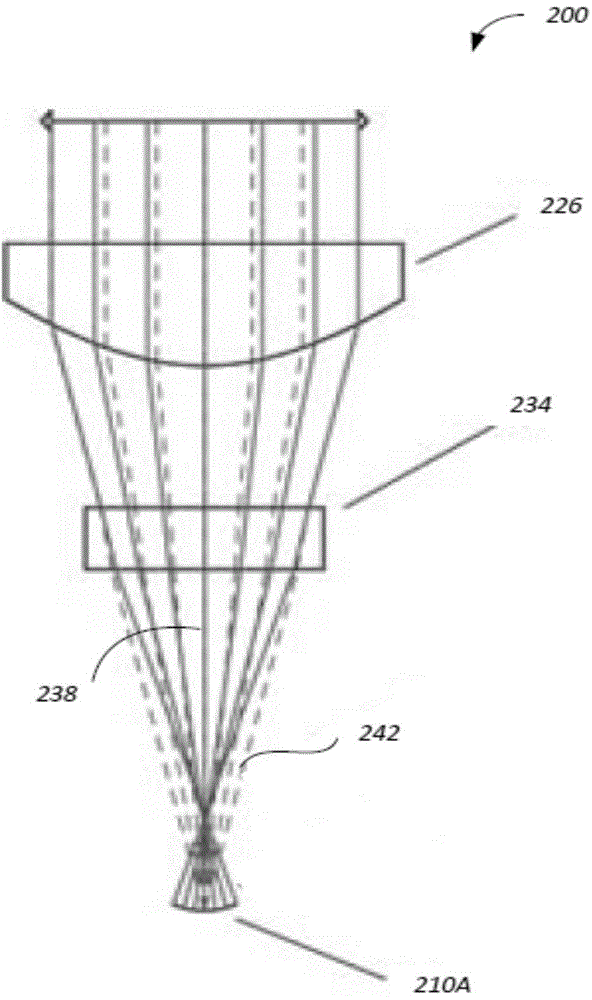

[0054] This embodiment provides a common path interference system, such as figure 1 As shown, the interference system is a single-arm interference system of the solution 100 of the present invention. To test an optical element 110 (eg, an aspheric lens) in the aspheric optical system 110A, a collimated beam 114 of wavelength λ from a coherent light source (in one approach—laser 118 ) will be used. The light beam 114 is collimated by using a collimating optical system 122 (which may include a lens or a plane mirror, for simplicity it is a collimating lens). During the collimation process, the light beam is further transmitted to a beam splitter 124 and a wavefront converging (for example, focusing) optical system 126 (simply speaking, a focusing lens), thereby forming a spatially focused light beam 130, which There is a spherical wavefront propagating along optical axis 132 . In the present invention, the space I in front of the collimating lens 122 is an object space, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com