Capsule alignment precision tester

A tester and accuracy technology, which is applied in the field of capsule centering precision tester, can solve the problems of inaccurate judgment of capsules, inability to distinguish them, high scrap rate, etc., and achieve the effects of saving manpower, facilitating detection, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

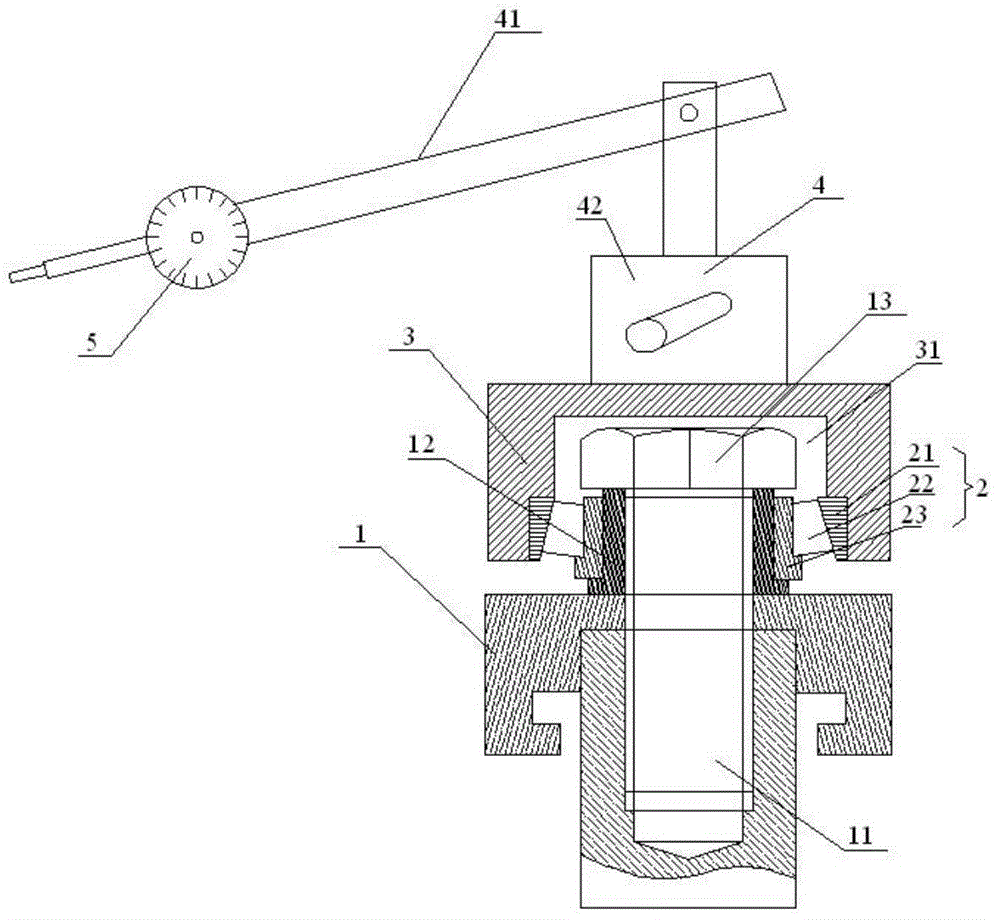

[0011] Hereinafter, the capsule centering accuracy tester of the present invention will be described in detail with reference to the drawings.

[0012] Capsule centering accuracy tester, including center mechanism 1, tapered roller bearing 2, ring seat 3, universal meter seat 4 and universal meter 5. Such as figure 1 As shown, a bolt 11 is provided in the center of the center mechanism 1, and the bolt 11 is screwed into the thread of the center mechanism 1 through a thread. In the middle position, the bolt 11 is higher than the center mechanism 1. The bolt 11 is covered with a nut 12, which is located between the bolt head 13 and the central mechanism 1. In order to facilitate the installation of the tapered roller bearing 2, the outer diameter of the nut 12 must be smaller than the outer diameter of the bolt head 13, so that it can be left Install tapered roller bearings 2 at a certain distance.

[0013] The ring seat 3 is installed above the center mechanism 1 through a tapered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com