Method for extracting fault features of rotating mechanical equipment

A technology of rotating mechanical equipment and fault characteristics, applied in the field of mechanical equipment fault diagnosis, can solve the problems of destroying data continuity, unable to realize continuous state monitoring, and reducing Fourier transform frequency domain resolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be described below by taking the bearing fault diagnosis of a certain type of wind turbine as an example in conjunction with the accompanying drawings.

[0029] 1. Sampling the vibration signal at equal time intervals and performing time domain processing to extract time domain features.

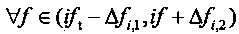

[0030] The analog signals output from the vibration sensor and the rotational speed sensor are transformed and amplified by the conditioning circuit, and the vibration signal is also subjected to anti-aliasing low-pass filtering, and then 200kbps digital sampling is performed synchronously. After the sampled vibration signal is processed by removing outliers, eliminating noise, filtering, and baseline normalization, the vibration signal x(n) at equal time intervals is obtained. Then calculate the effective value, variance, standard deviation, skew index, degree index, waveform index, peak index, pulse index, margin index and ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com