Longitudinal multi-level spectrum loading test bed provided with control arm assembly and used for auxiliary frame as well as test method adopting test bed

A loading test and sub-frame technology, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of long test period, single load, and affecting the fatigue performance of parts, so as to shorten the test period, The effect of high test accuracy and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

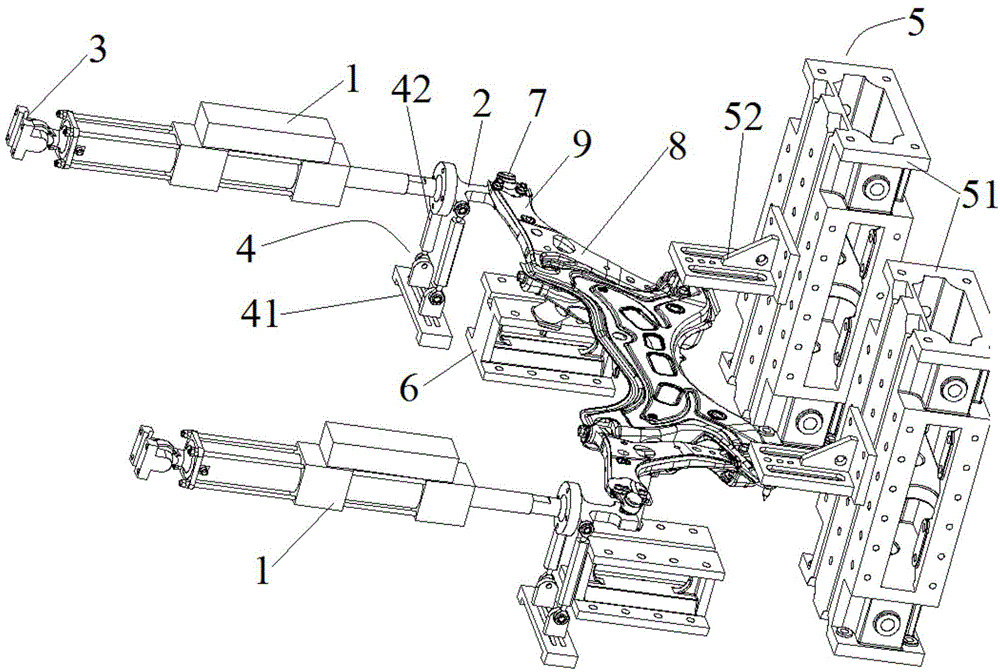

[0025] Such as figure 2 As shown, the present invention provides a longitudinal multi-stage spectrum loading test bench with a subframe with a control arm assembly. The subframe with a control arm assembly is composed of a subframe, two control arms and two ball pins The two control arms are respectively connected to the sub-frame on one side of the sub-frame, and the two ball pins are respectively arranged on one control arm. The test bench includes the first combination bracket for fixing the subframe and two drivers for applying load to the ball pins on the control arms on both sides of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com