Stamping processing online visual inspection device and stamping processing online visual inspection method

A visual inspection device and stamping processing technology, applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as low detection efficiency and out-of-tolerance dimensions, and achieve easy acquisition, avoid continuous production, and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in combination with specific embodiments.

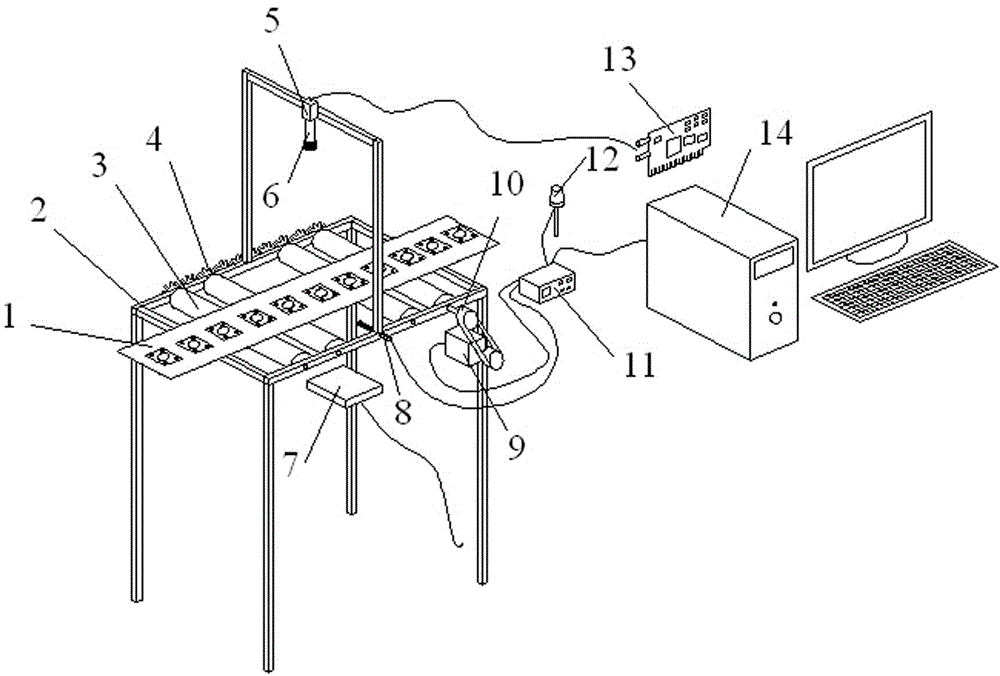

[0034] Such as figure 1 Shown: an online visual inspection device for stamping processing, the device includes a conveying mechanism, a position detection component, an image acquisition component, a central processing module, a control unit 11, an audible and visual alarm component 12, and a workbench 2, on the table top of the workbench 2 A visual inspection area for the stamping strip 1 to be tested is provided;

[0035] Described conveying mechanism is made up of belt 10, stepper motor 9, some rollers 3 and some gears 4, and roller 3 is installed in the workbench 2 table tops of both sides of visual inspection area of stamping strip 1 to be tested, and all rollers The same end of the column 3 is provided with a gear 4, and an intermediate gear is provided between adjacent rollers, and the movement is transmitted through the meshing between these gears, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com