Image segmentation method for micro-fine cohesive core particles based on angular point and curvature detection

A curvature detection, image segmentation technology, applied in image analysis, image enhancement, image data processing and other directions, can solve problems such as large errors, and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

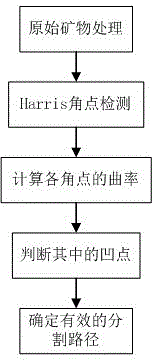

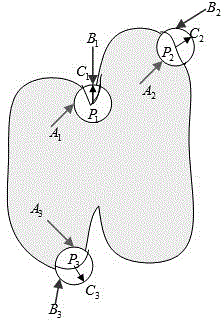

[0020] Such as figure 1 As shown, the method for image segmentation of fine grained ore particles based on corner point and curvature detection of the present invention, its steps are as follows:

[0021] a. Use a scanning electron microscope to take pictures of the ground ore particles, and use the smooth function to sequentially smooth the ore particle images, image thresholding, morphological filtering, and remove edge particles, so as to complete the binary image of the ore particles change;

[0022] b. Select the image with fine particle adhesion in the binarized ore particle image as the target area, and perform Harris corner detection on the ore particle image in the target area:

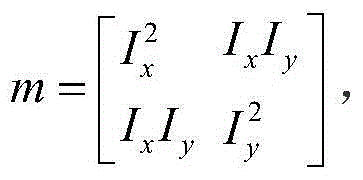

[0023] 1) Use the horizontal and vertical difference operators to filter each pixel in the ore particle image of the target area, and obtain the first derivative I of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com