6/8/12-pole single-winding three-speed asynchronous motor stator winding mode

An asynchronous motor and stator winding technology, which is applied to asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of frequent motor replacement, reduction of rotation speed, failure to achieve speed regulation and energy saving, etc., to improve power quality and operation reliability. , the effect of eliminating the circulation loss and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

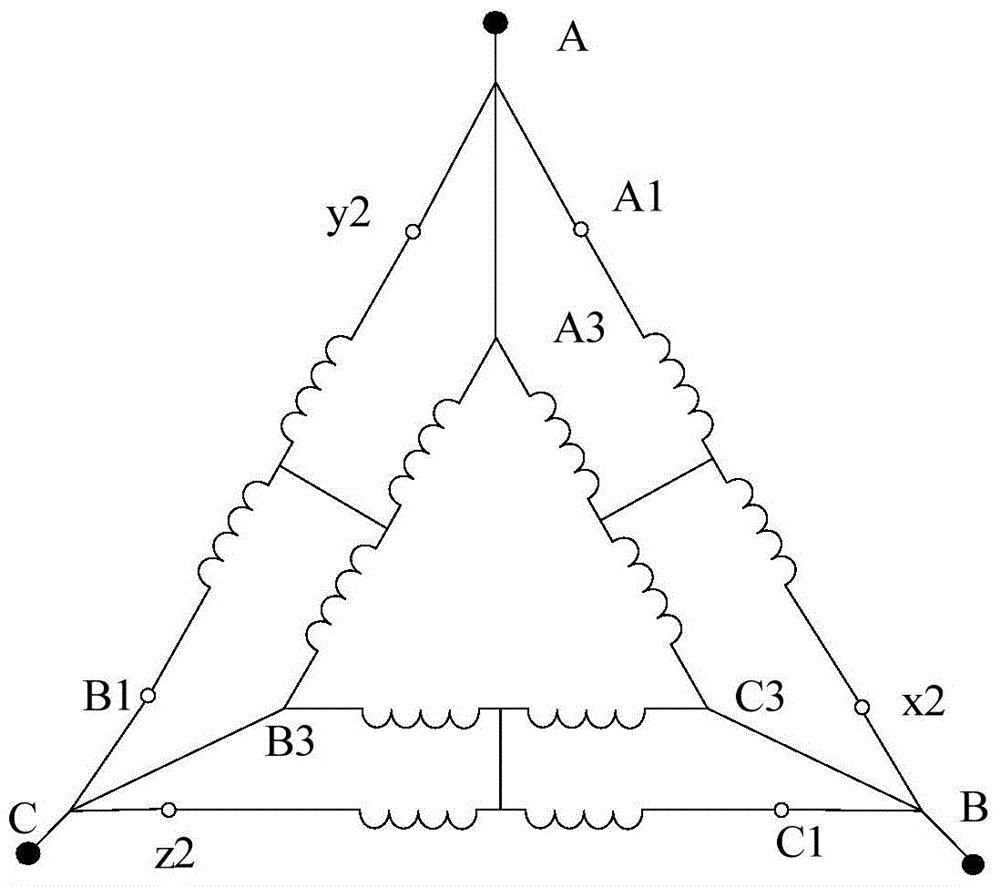

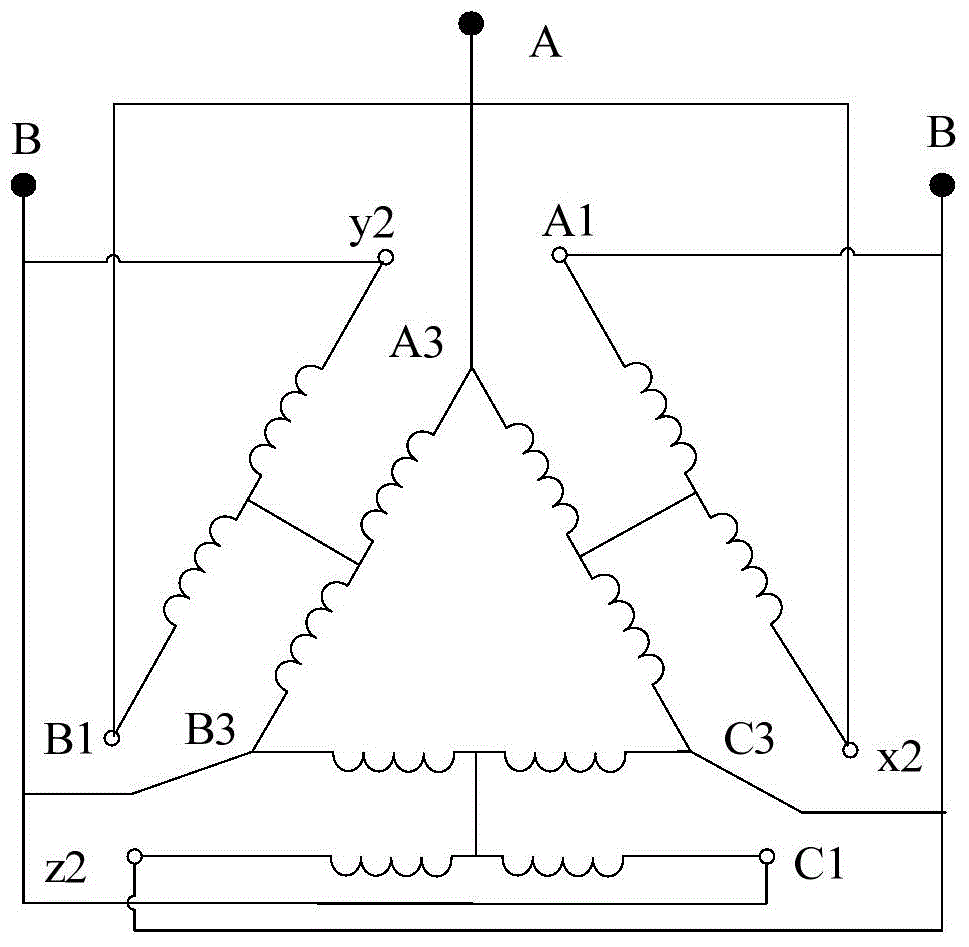

Embodiment 1

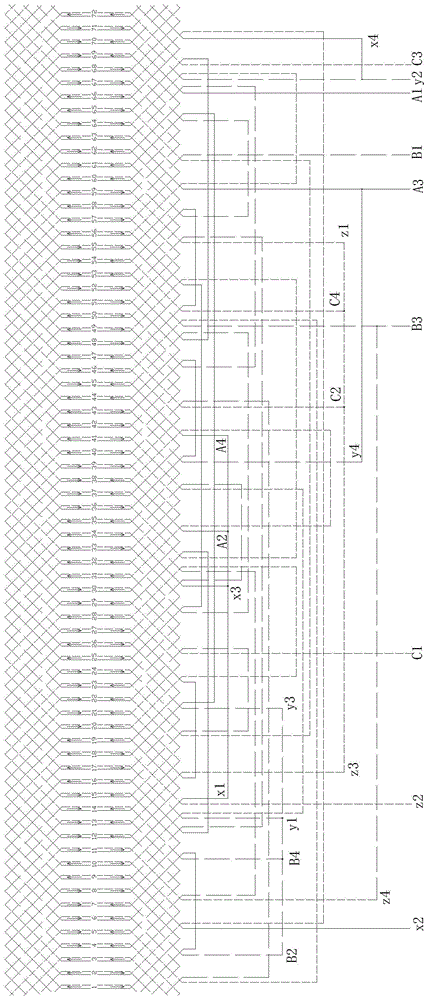

[0039] The number of stator and rotor slots is 72 / 56 respectively, the base adopts 280, the length of the stator core is 260mm, the rotor adopts inclined slots, and the corresponding synchronous speeds are 1000 rpm and 750 rpm when the motor adopts 6, 8 and 12 poles respectively. The corresponding rated power is 45kW, 30kW, and 18.5kW respectively, and the rated operating efficiencies at the three speeds are 83%, 87%, and 83%, respectively. In an oilfield field application, the power saving effect is 13% %.

Embodiment 2

[0041] Still taking the single-winding three-speed motor in Embodiment 1 as an example, its starting current waveform during 6-pole operation is shown in the attached Figure 5 As shown, the starting current is 664A; the starting speed curve in 6-pole operation is as follows Image 6 As shown, the time to reach a stable speed is about 0.9 seconds, and the speed after entering the steady state is about 978 rpm; the full-load steady-state current waveform during 6-pole operation is as follows Figure 7 As shown, the current value in steady state operation is about 106A.

Embodiment 3

[0043] Still taking the single-winding three-speed motor in Embodiment 1 as an example, its starting current waveform during 8-pole operation is as follows: Figure 8 As shown, the maximum starting current can reach 654.5A; the starting torque and speed curves of 8-pole operation are as follows Figure 9 with Figure 10 As shown, the time to reach a stable speed is about 0.6 seconds, and the speed in a steady state is about 729 rpm; the full-load steady-state current waveform in 8-pole operation is as follows Figure 11 As shown, the current amplitude is about 87A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com